Fabricated steel structure beam and column joint capable of consuming energy in earthquake, and manufacturing method thereof

A beam-column joint and assembled technology, which is applied in building structure, earthquake resistance, building components, etc., can solve the problems of difficult to achieve strong joints, poor bolt hole energy dissipation capacity, complex bolt hole technology, etc., and achieve repair costs Low energy consumption, strong energy consumption and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

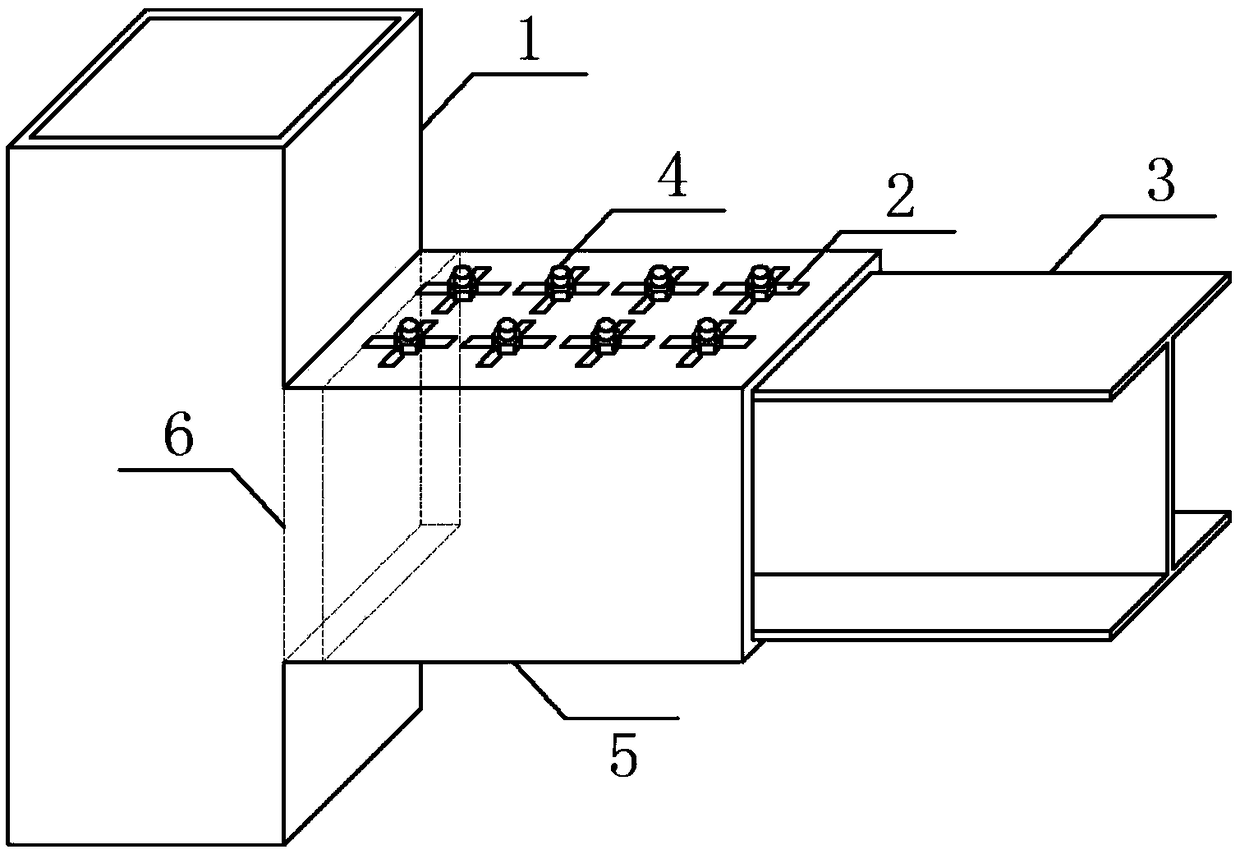

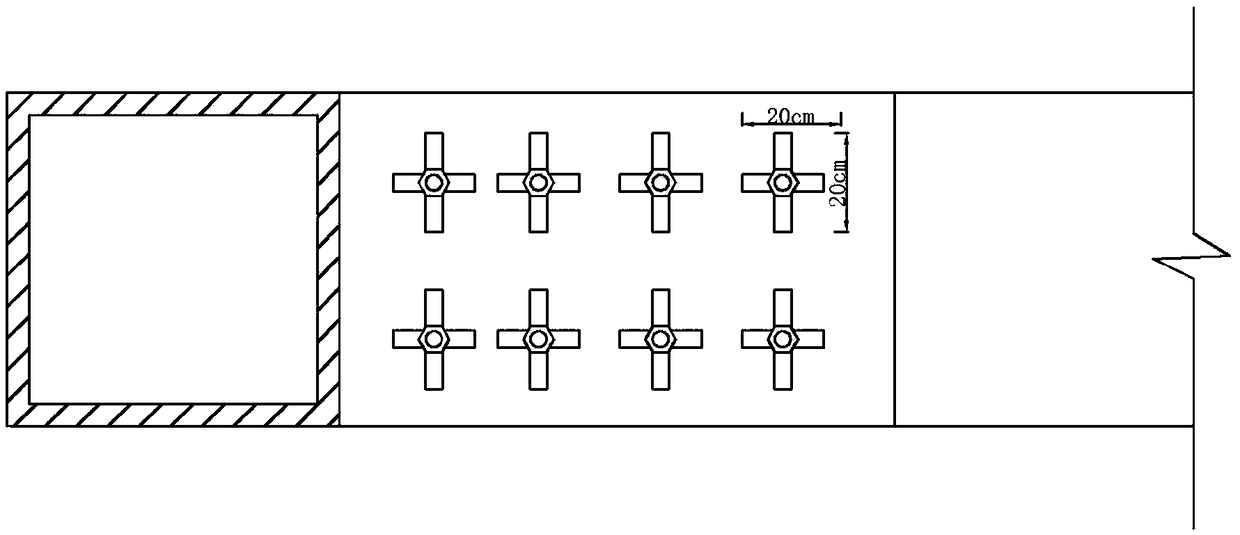

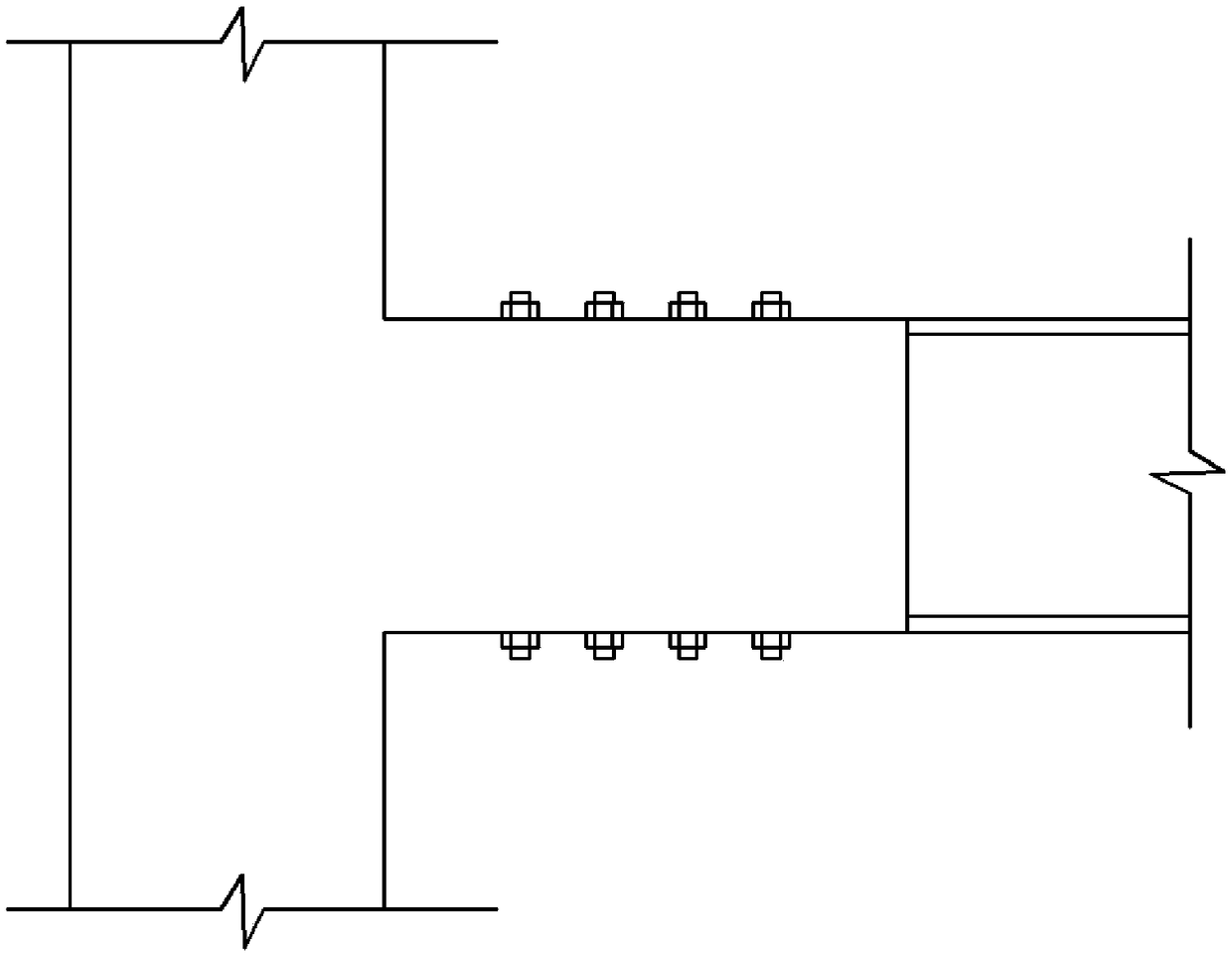

[0020] Such as figure 1 As shown, an assembled beam-column joint of steel structure that can dissipate energy in an earthquake includes a column 1, a beam 2, and high-strength bolts 3; the column 1 includes a horizontal sleeve 11, and the beam 2 extends into the horizontal sleeve 11. The sleeve 11 is provided with cross bolt sliding grooves 111; the beam 1 is specifically an I-beam, and the flanges on both sides of the beam 1 are provided with cross bolt sliding grooves 111 corresponding to the cross bolt sliding grooves 111 on the horizontal sleeve 11. Sliding groove: the flanges on both sides of the beam 1 are respectively connected with the two surfaces of the sleeve 11 provided with the cross bolt sliding groove 111 . The high-strength bolts 3 pass through the cross bolt sliding grooves 111 on the flange of the beam 1 to connect and fix the beam 1 and the sleeve 11 .

[0021] A shock absorber 4 is provided at the contact surface between the beam 2 and the vertical column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com