Connecting mode and structure of reinforced concrete hollow pipe pier joints based on steel plate connection

A reinforced concrete and node connection technology, which is applied in infrastructure engineering, bridge parts, bridge materials, etc., can solve the problems of plastic hinges that are difficult to repair, life-threatening, and difficult bridge repairs, so as to increase energy consumption and reduce plasticity. Distortion and vibration-absorbing effects are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

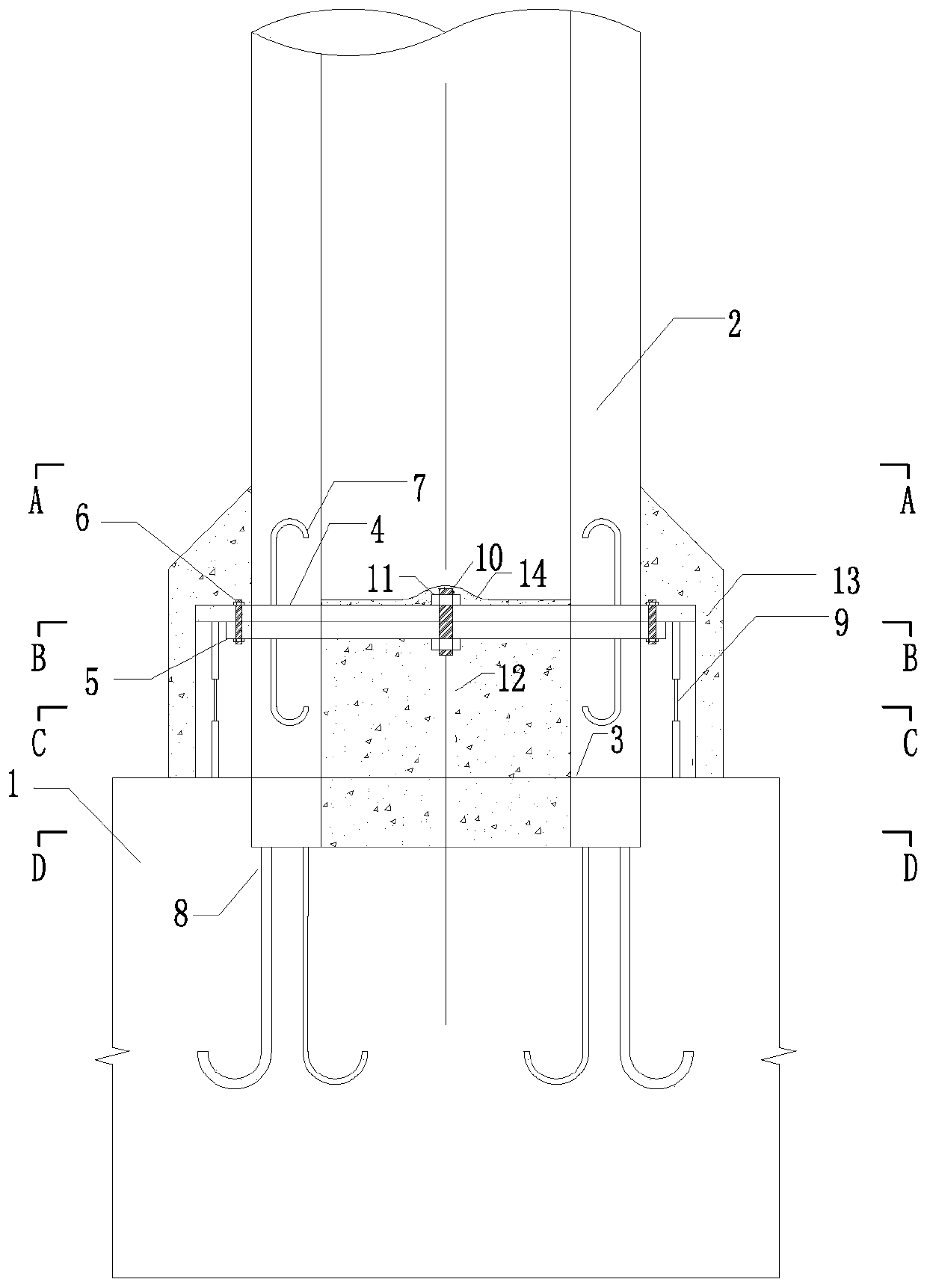

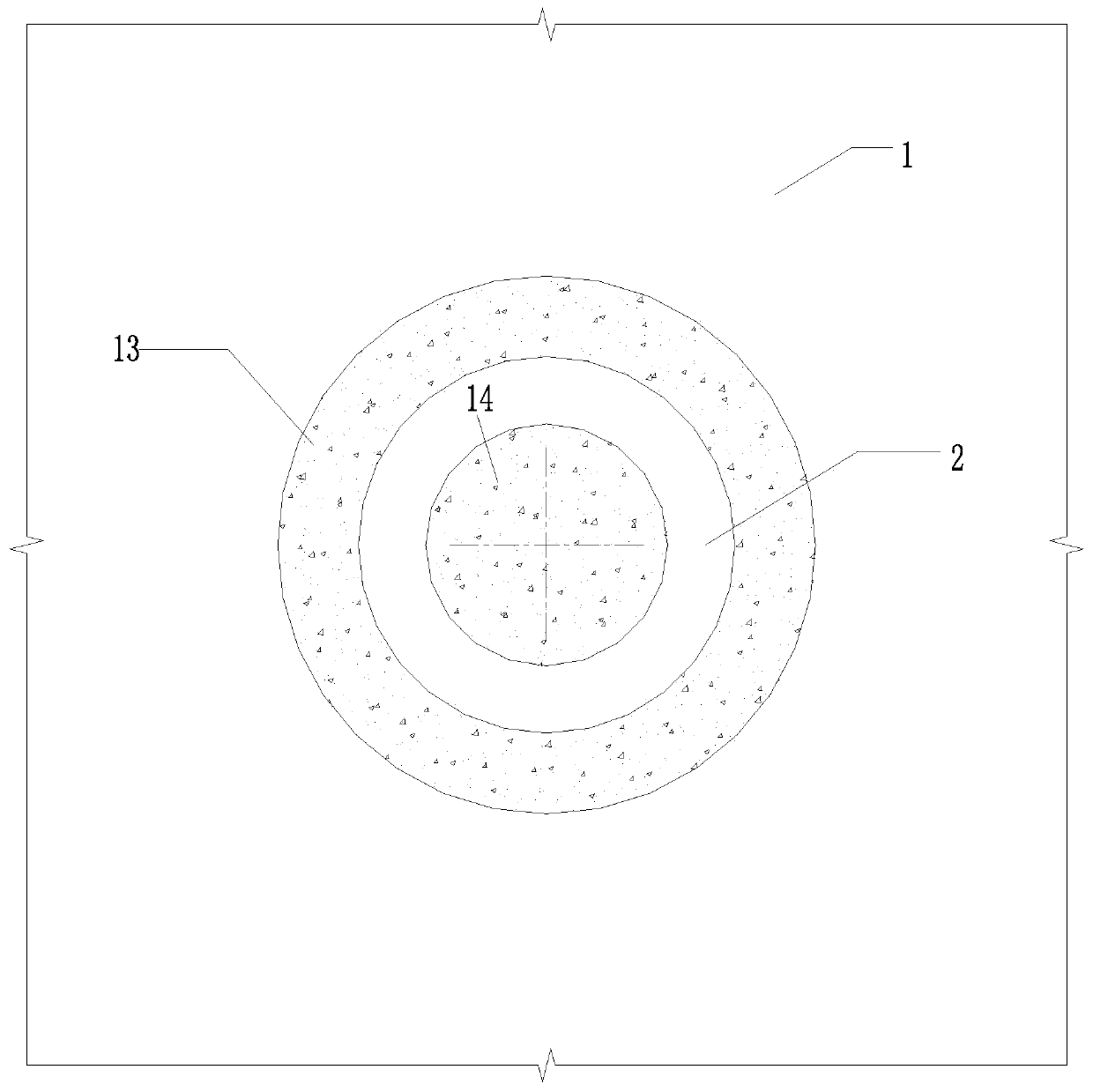

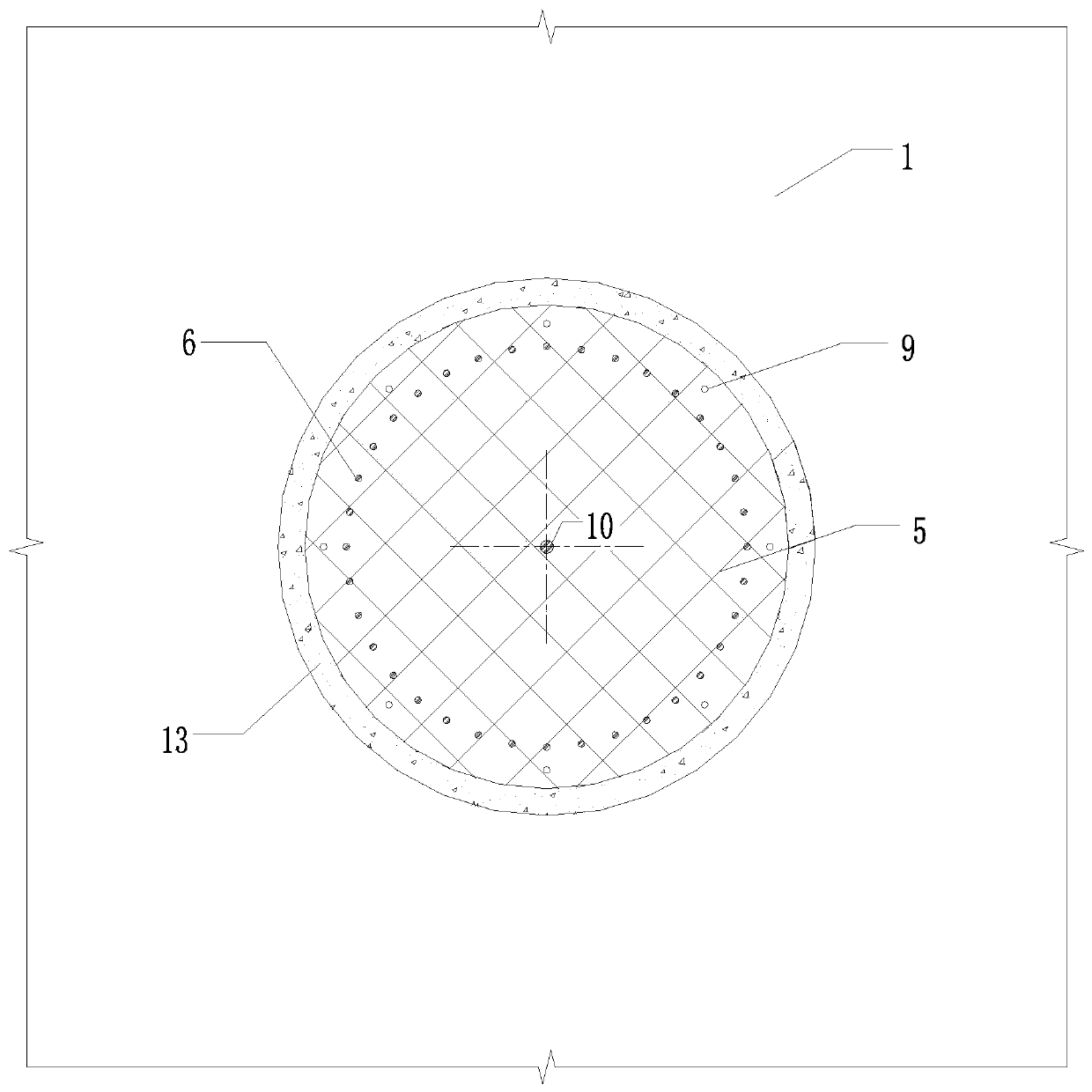

[0037] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0038] The realization of the connection mode and structure of the above-mentioned reinforced concrete hollow pipe pier joint based on steel plate connection mainly includes the following steps:

[0039] S1 Prefabricate pier section 2 and pier section 3 in the factory and reserve steel plates.

[0040] S2 Pouring low-strength concrete in the middle area of the prefabricated pier segment 3 and presetting SMA tendons.

[0041] S3 inserts the prefabricated pier segment 3 into the reinforcement cage of the cap, and pours the cap.

[0042] S4 connects the prefabricated pier segment 2 and the prefabricated pier segment 3 through steel plates with SMA bolts, and tensions the SMA tendons.

[0043] S5 installs a plurality of dampers circumferentially between the bottom surface of the steel plate (4) and the top surface of the platform.

[0044] S6 Pouring low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com