High-precision no-load current testing device for electromagnetic voltage transformer

A technology of voltage transformer and no-load current, applied in measuring devices, measuring current/voltage, instruments, etc., can solve the problems of low test accuracy, easy to burn ammeter, poor test safety, etc., to improve work efficiency, not easy Error, simple wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

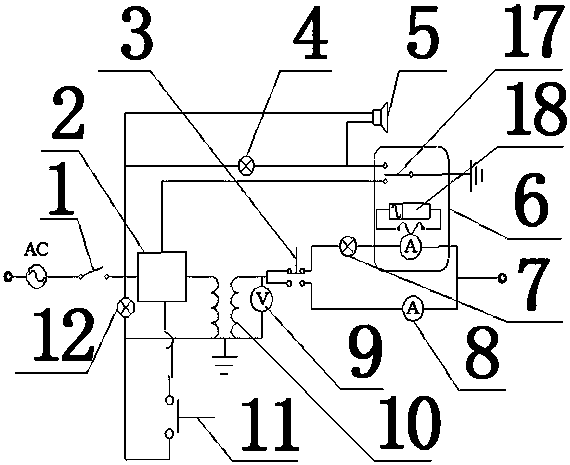

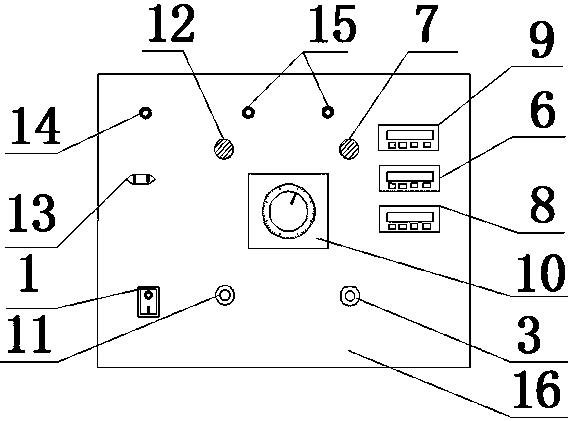

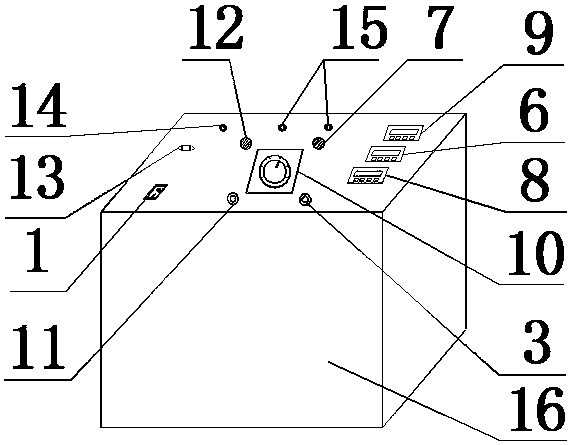

[0019] Embodiment 1: A high-precision electromagnetic voltage transformer no-load current test device, the structure of which is: a voltage adjustment knob (10) is arranged on the upper surface of the main body (16) of the tester, and the left side of the voltage adjustment knob (10) is A power switch K1 (1) and a power jack (13) are provided, an ammeter A1 (6), an ammeter A2 (8) and a voltmeter (9) are arranged on the right side of the voltage adjustment knob (10), and the voltage adjustment knob (10 ) is provided with contactor conduction blocking switch K2 (11) and switch K3 (3), above the voltage adjustment knob (10) is provided with display lamp L1 (12) and display lamp L3 (7), ammeter A1 (6 ) is equipped with an emergency switch (17) and a fuse (18), and the upper surface of the tester main body (16) is also provided with a ground wire jack (14) and a measuring pen connection hole (15); the contact in the circuit The contactor (2) is connected to the positive pole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com