Intelligent optimization algorithm based on load balancing

An intelligent optimization algorithm and balanced technology, applied in computing, commerce, instruments, etc., can solve the problems of too random loading, prolonged operation time, and uneven loading of shelves, so as to reduce the risk factor, improve economic efficiency, and improve loading The effect of the degree of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

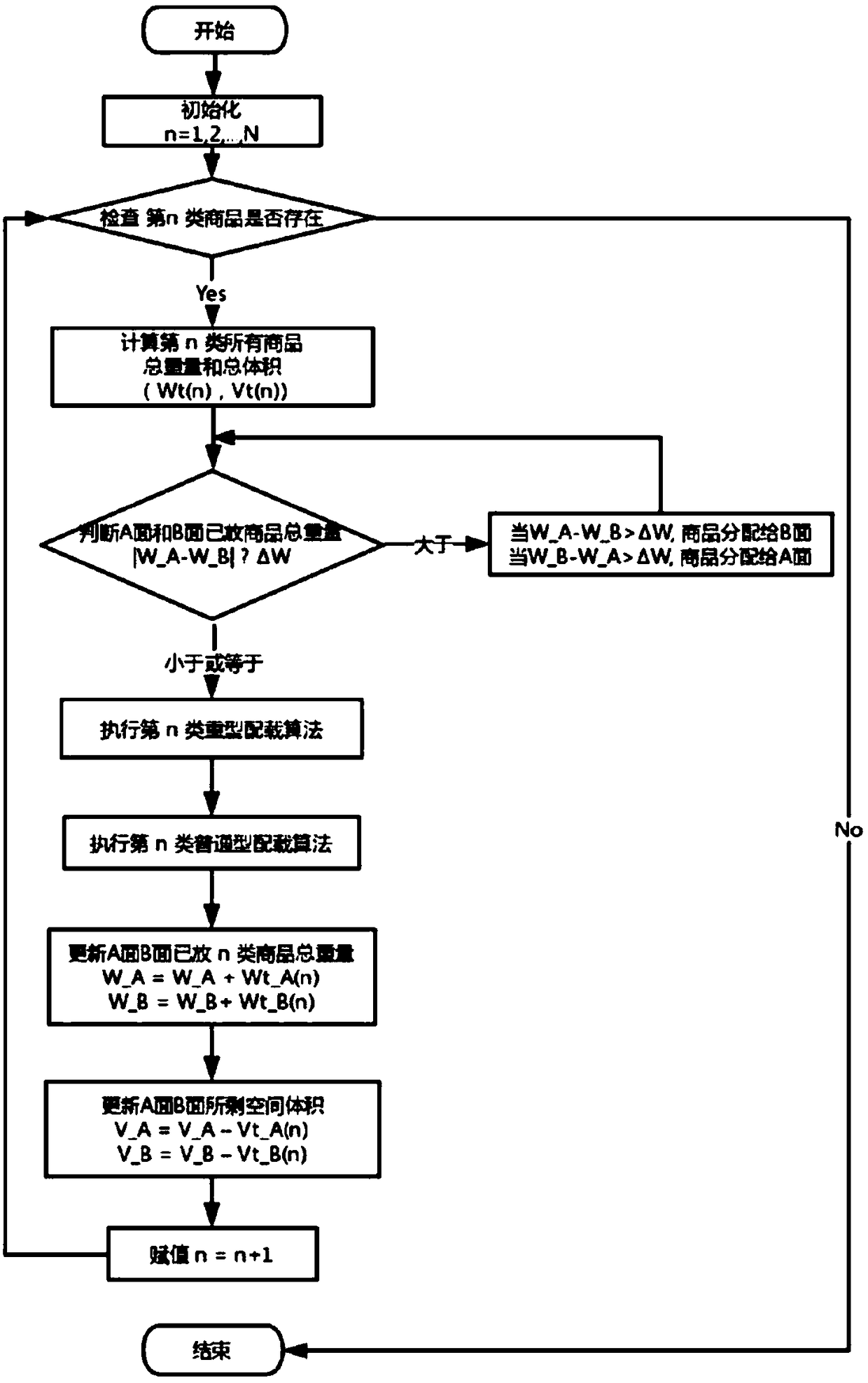

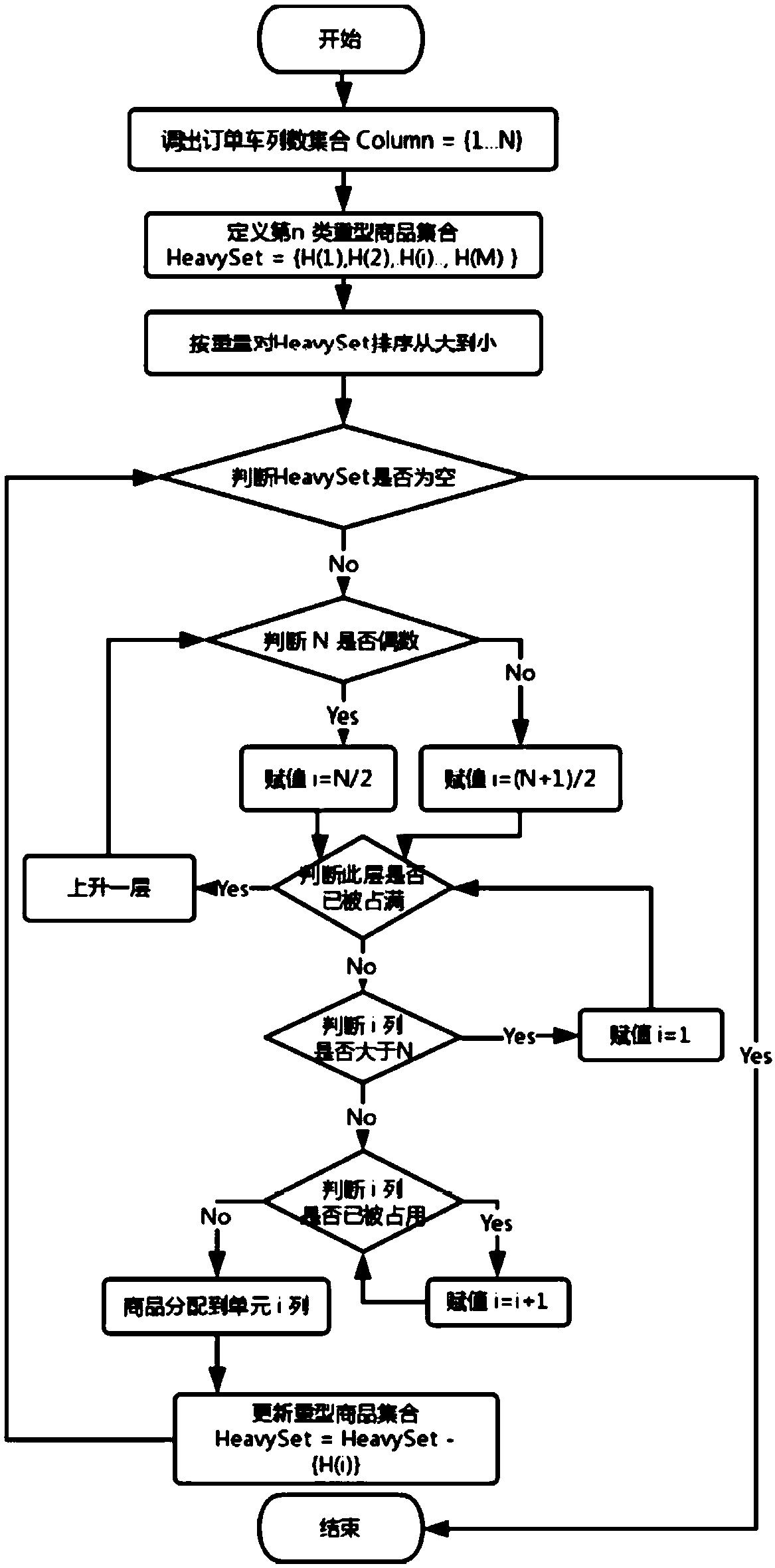

[0065] An intelligent optimization algorithm based on load balancing, comprising the following steps:

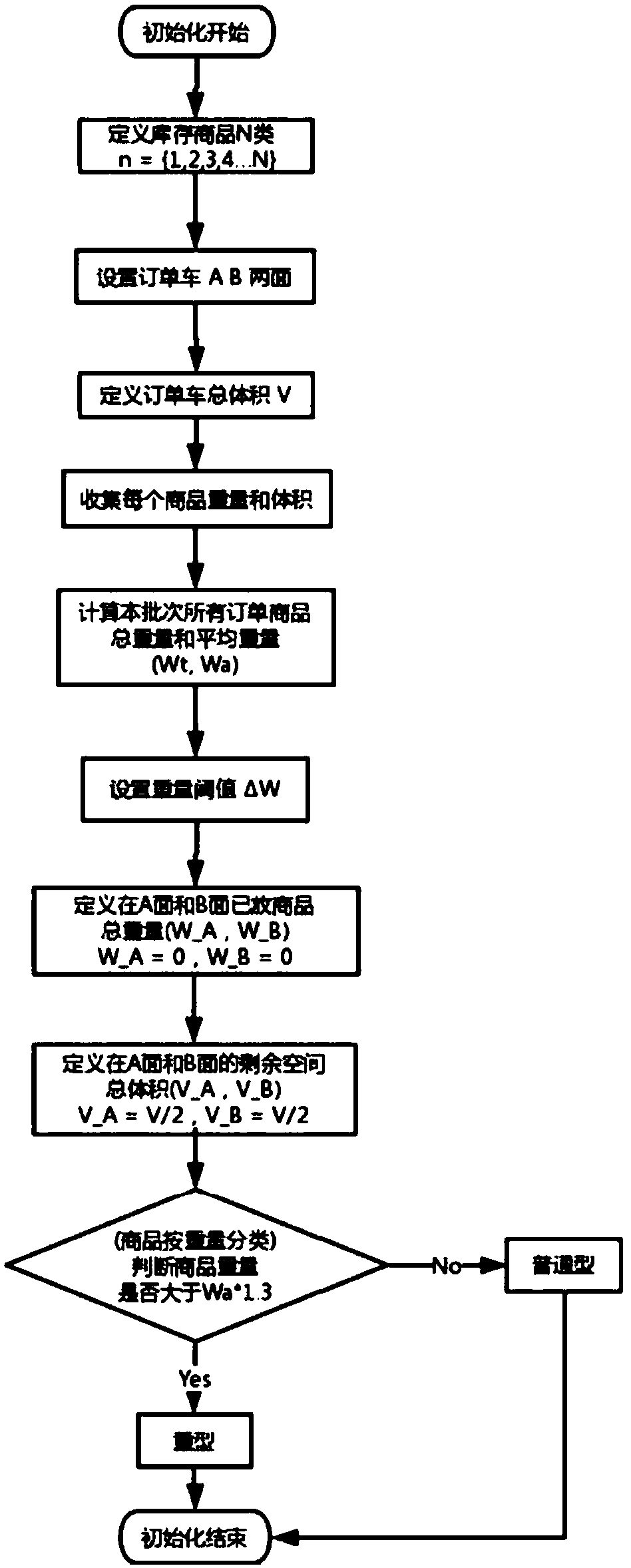

[0066] S1. Initialization:

[0067] i. Inventory goods are divided into N categories, N=1, 2, 3, 4...n;

[0068] ii. The order cart unit has both front and back sides for delivery (side A and side B);

[0069] iii. The total volume of the order cart is a constant V;

[0070] iv. Extract the weight and volume of each commodity;

[0071] v. Calculate the total weight Wt and average weight Wa of all order items in this batch;

[0072] vi. Define the total weight W_A and W_B of the goods on the A side and the B side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com