Front-lifting type double-contact connector

A connector and double-contact technology, which is applied in the direction of connection, parts of connection devices, protective grounding/shielding devices of connection parts, etc., can solve inconvenient insertion, high installation requirements, and inability to insert wrong FPC/FFC cables, etc. problem, to achieve the effect of easy opening of the flip cover, not easy to fall off, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

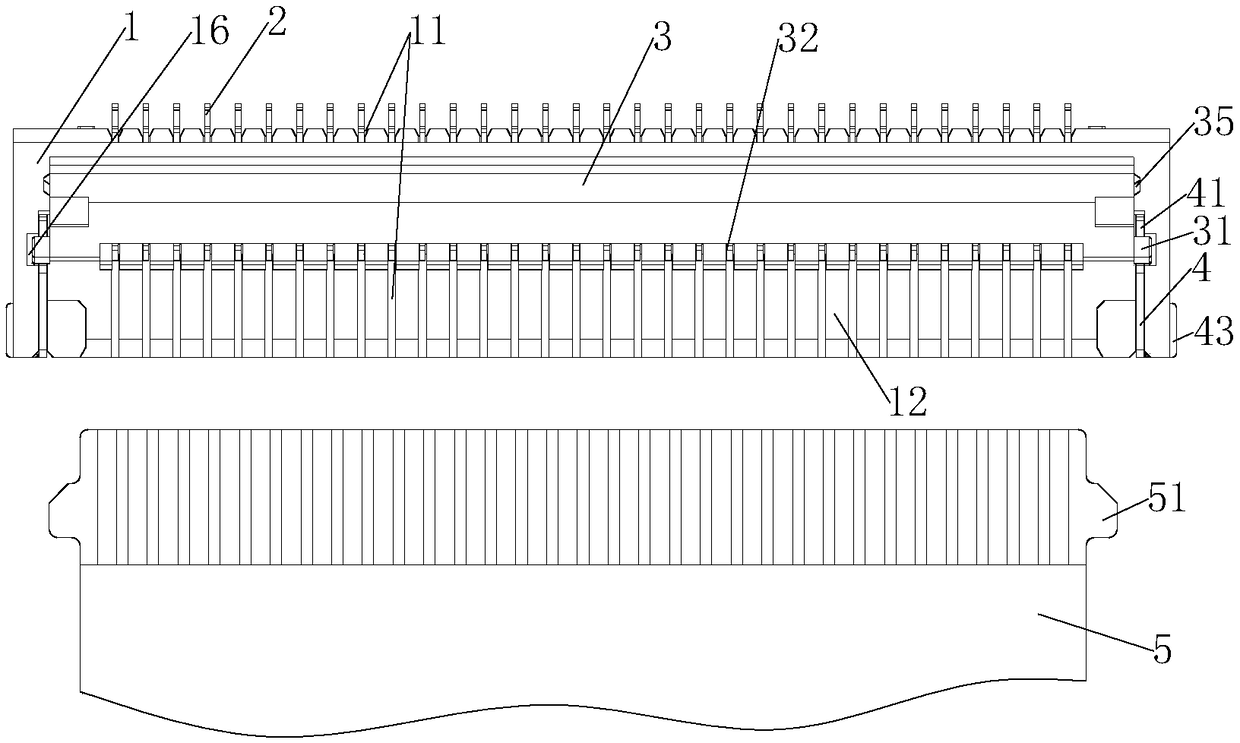

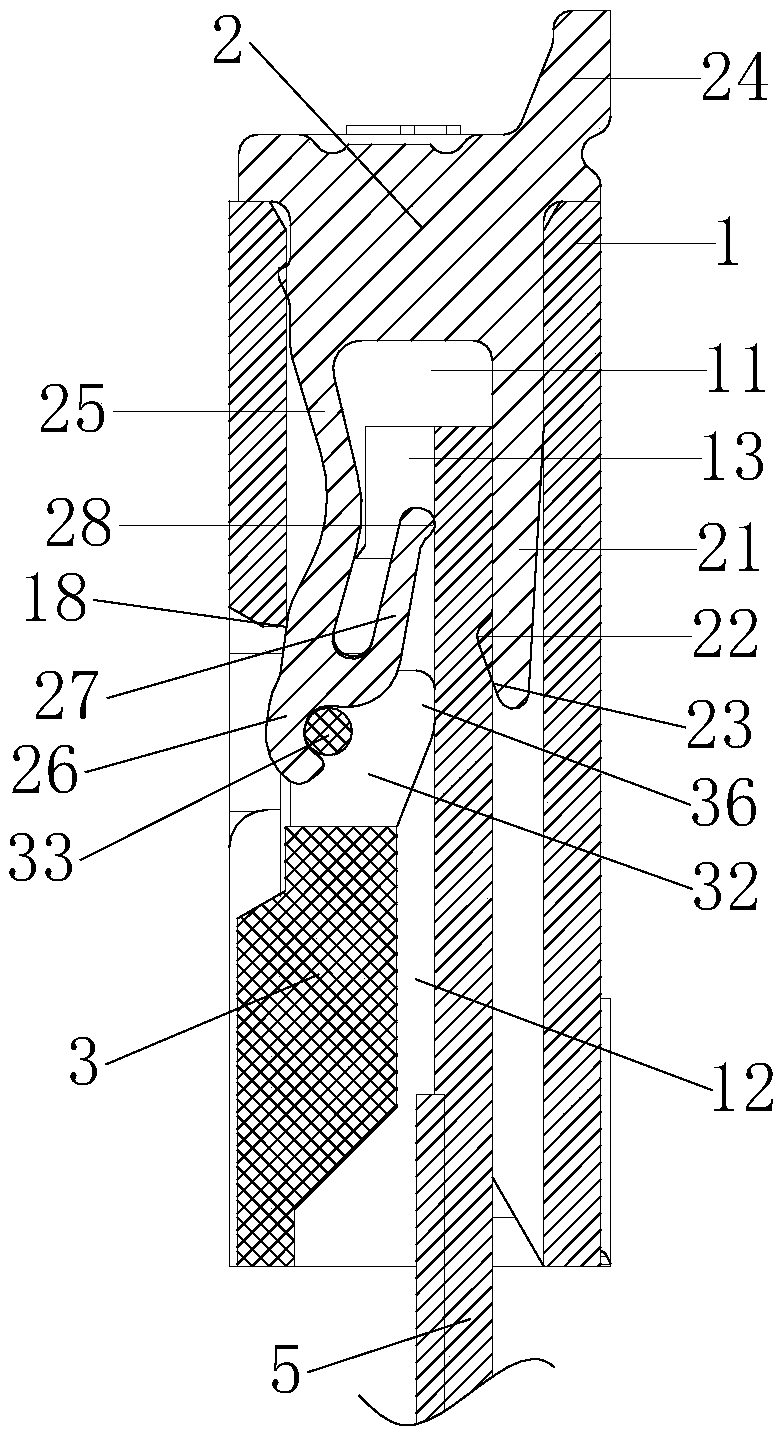

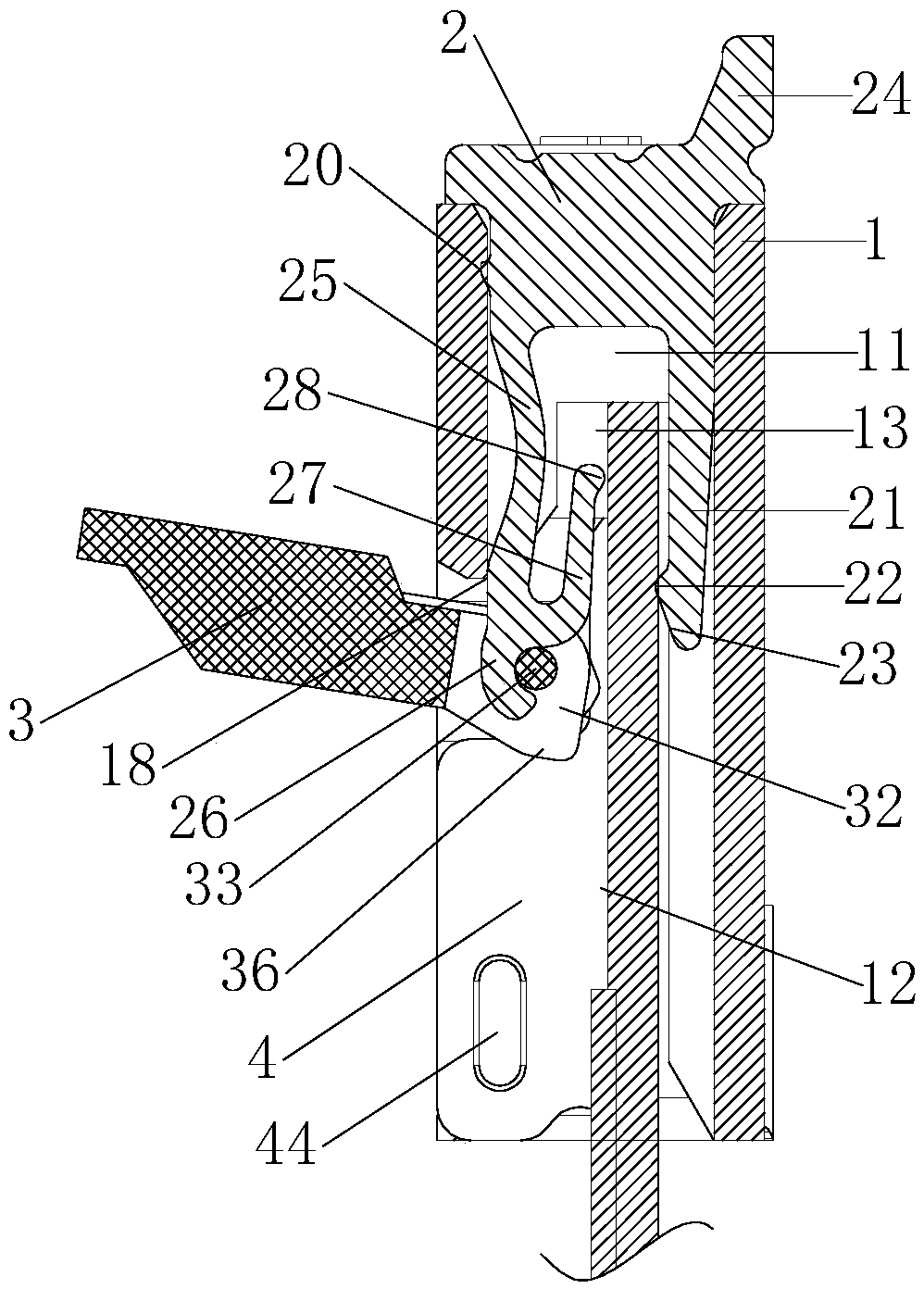

[0039] Such as Figure 1 to Figure 7 As shown, the front flip-type dual-contact connector includes an insulating base 1, a flip cover 3, a conductive terminal 2, and a ground terminal 4. The front end of the insulating base 1 is provided with a cable slot 13 and a grounding slot 14, and the grounding plug The slots 14 are located at both ends of the insulating base 1, and the grounding terminals 4 are inserted into the grounding slots 14. The rear end of the insulating base 1 is arrayed with a plurality of terminal slots 11, and the terminal slots 11 communicate with the cable slot 13 and are conductive. The terminal 2 is inserted in the terminal slot 11, the conductive contact of the conductive terminal 2 is located in the cable slot 13, the top of the insulating base 1 is provided with a cover plate groove 12, and the flip cover 3 is rotatably installed in the cover plate groove 12.

[0040] Such as Figure 1 to Figure 4 As shown, the cover slot 12 passes through the front end ...

Embodiment 2

[0055] On the basis of the first embodiment, the upper elastic arm 25 is also provided with a compression elastic arm 27, and an elastic groove 271 is provided between the compression elastic arm 27 and the upper elastic arm 25, and the elastic arm 27 and the upper elastic arm are compressed. 25 is U-shaped, and the upper conductive contact 28 is located at the end of the elastic pressing arm 27.

[0056] Compressing the elastic arm 27 can increase a larger deformation space, and can be applied to FFC cables 5 of different thicknesses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com