Electromagnetically operated valve

An electromagnetic drive, electromagnetic coil technology, applied in engine components, machines/engines, charging systems, etc., can solve problems such as discontinuity, and achieve high dynamic strength and easy connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

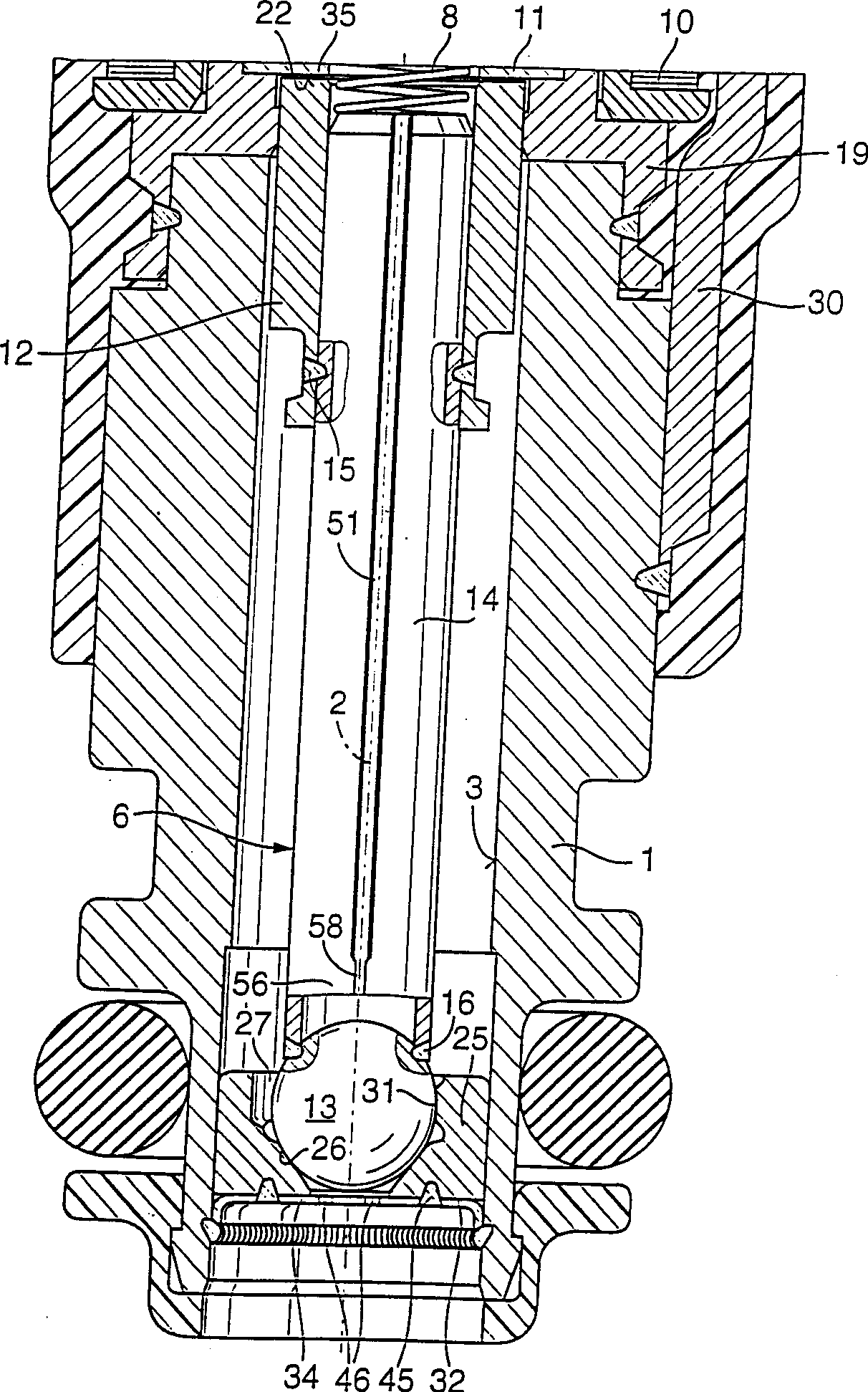

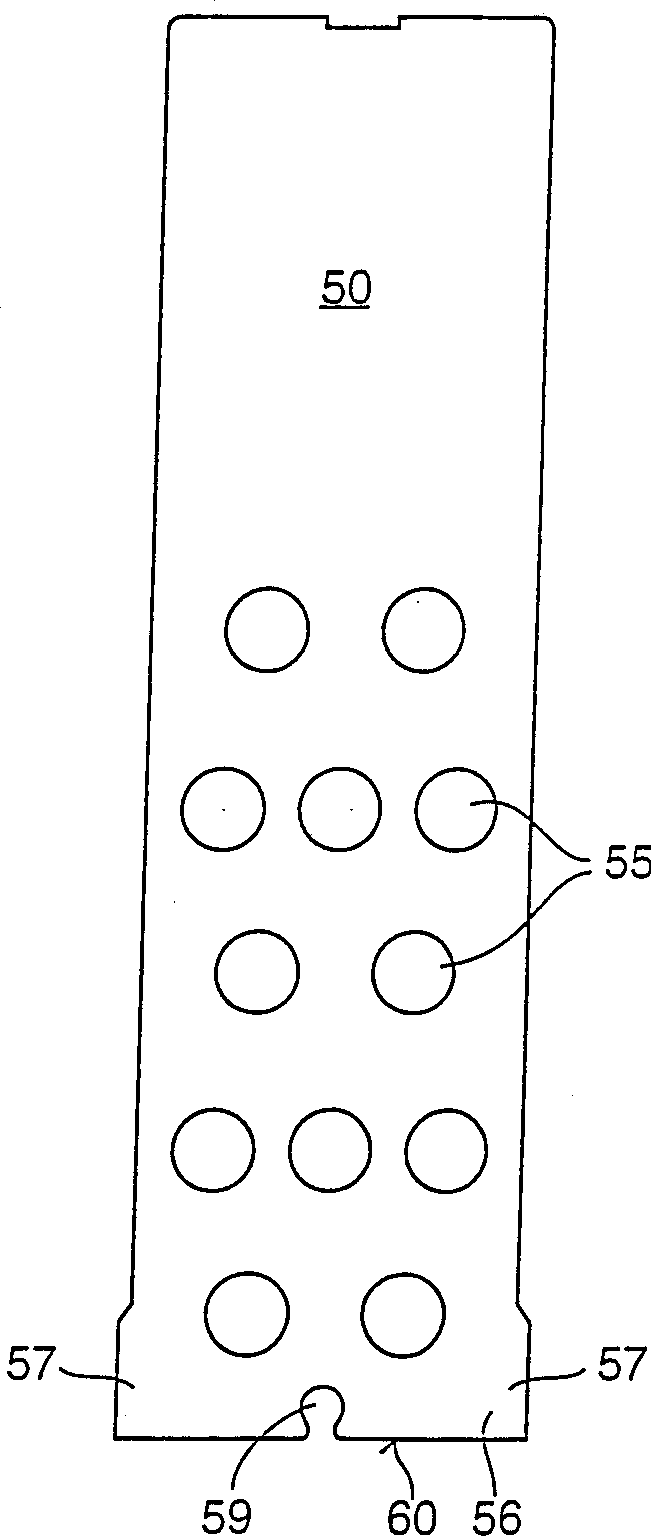

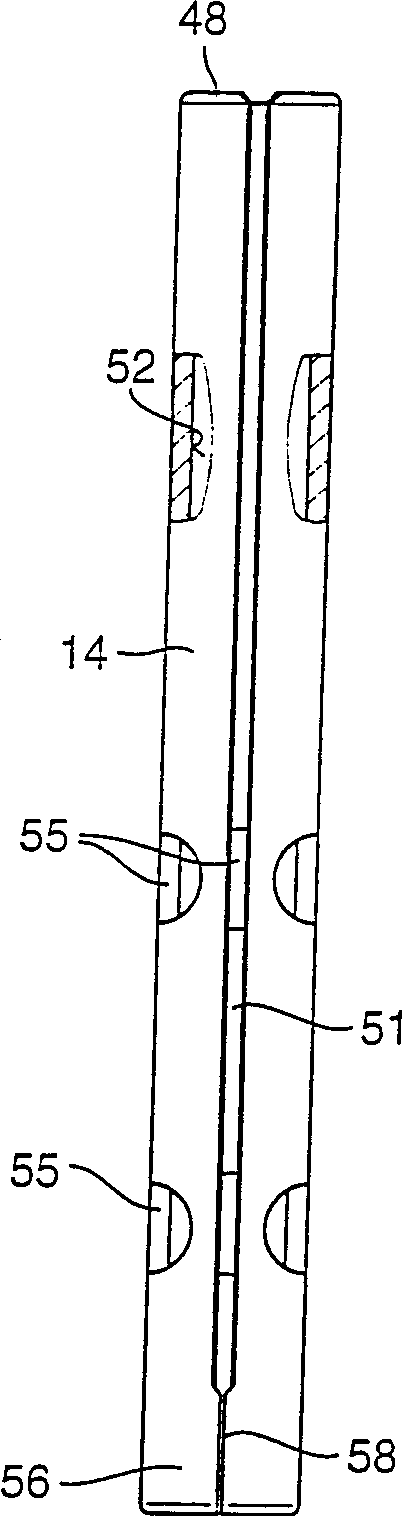

[0015] In FIG. 1 , an electromagnetically actuatable valve in the form of an injection valve of a fuel injection system of a mixture-compressing, forced-ignition internal combustion engine is shown as part of the exemplary embodiment. The valve has a tubular seat carrier 1 in which a longitudinal bore 3 is formed coaxially to the valve longitudinal axis 2 . An axially displaceable valve needle 6 is arranged in the longitudinal bore 3 .

[0016] Solenoid actuation of the valve takes place in a known manner. A solenoid circuit, only partially shown, with a solenoid coil 10 , a core 11 and an armature 12 is used to move the valve needle axially and thus to open or close the valve against the spring force of the return spring 8 . The valve needle 6 consists of an armature 12 , an eg spherical valve closing body 13 and a connecting piece 14 connecting the two parts, wherein the connecting piece 14 has a tubular shape. The return spring 8 bears with its lower end on the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com