Traction adjusting device of wire tying machine

The technology of an adjusting device and a wire tying machine is applied in the direction of conveying sausages, ligating sausage casings, slaughtering and other directions in a horizontal position. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

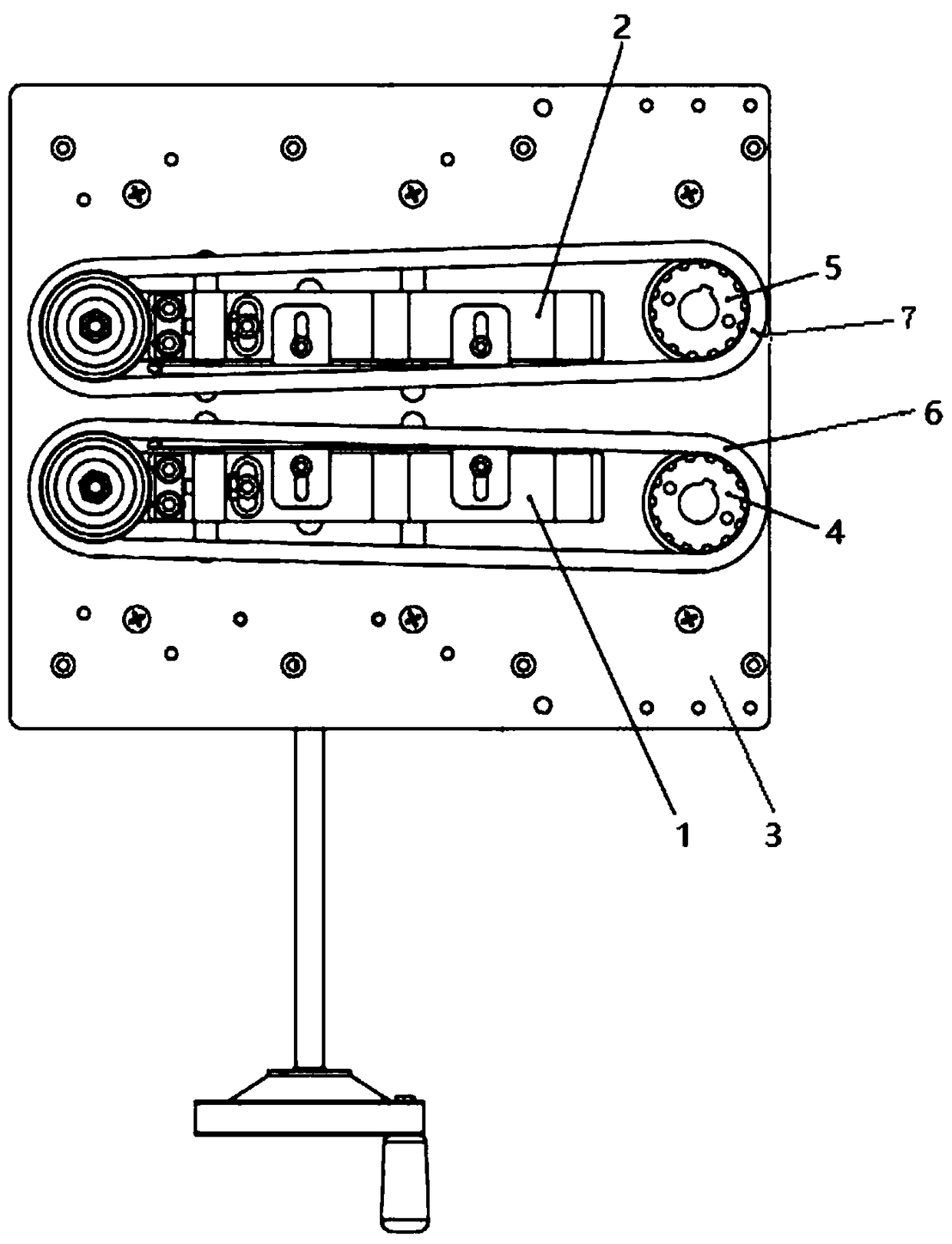

[0061] The invention provides a traction adjustment device for a wire binding machine, which includes a left traction guide mechanism 1, a right traction guide mechanism 2, a panel 3 and a single-channel spacing adjustment device.

[0062] The left traction guide mechanism 1 and the right traction guide mechanism 2 are symmetrically arranged and a single conveying channel is formed between them, and the left traction guide mechanism 1 and the right traction guide mechanism 2 are slidably connected with the panel 3 .

[0063] The single-channel spacing adjustment device includes a driving device and a single-channel transmission device. The driving device drives the single-channel transmission device to move synchronously. The single-channel transmission device drives the left traction guide mechanism 1 and the right traction guide mechanism 2 to move to adjust the distance between them.

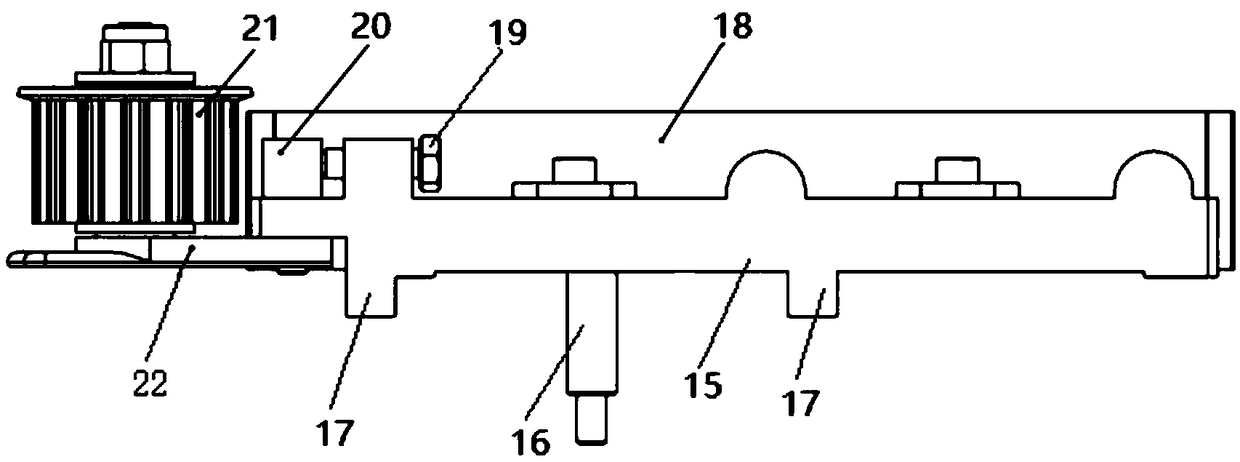

[0064] Specifically, the left traction guiding mechanism 1 includes a left driving synchro...

Embodiment 2

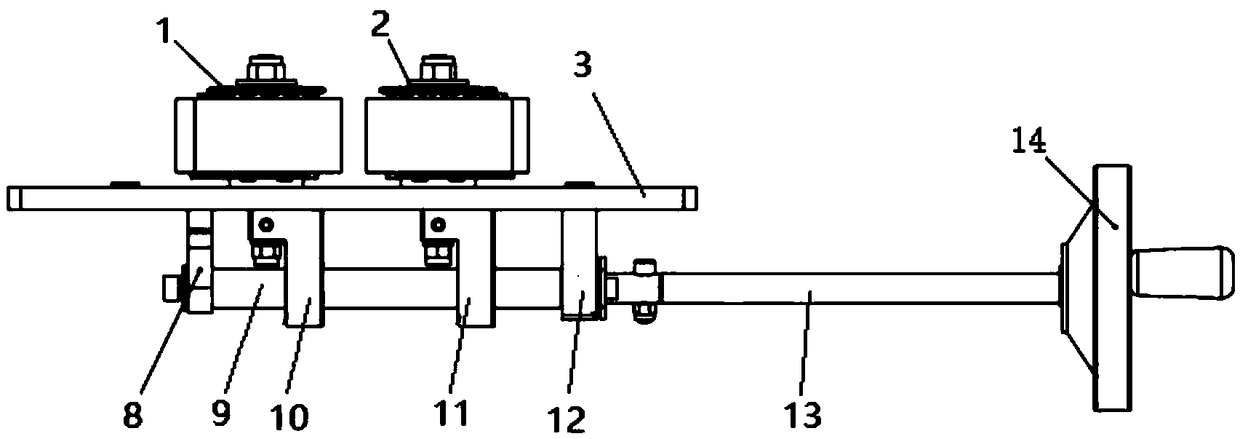

[0076] This embodiment is further improved on the basis of Embodiment 1. In this embodiment, a plurality of wire binding machine traction adjustment devices are placed side by side on the panel 3. Preferably, in order to save the space of the equipment itself, a 3. Place 2 binding machine traction adjustment devices side by side to form a double conveying channel device. It is just that the transmission device for adjusting the spacing is different from the single-channel transmission device of Embodiment 1.

[0077] Provisions: in use, the side of the panel 3 close to and facing the ground is the bottom surface, and the side facing away from the ground is the top surface.

[0078] Specifically, two binding machine traction adjustment devices are placed side by side on the panel 3, and a dual-channel spacing adjustment device is arranged on the bottom surface of the panel 3. The dual-channel spacing adjustment device includes a driving device and a dual-channel transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com