Oyster shell prying device

A technology for prying oyster shells and oysters, which is applied in the field of food processing equipment, and can solve problems such as scratching fingers, time-consuming and laborious, and exacerbating the difficulty of prying oyster shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

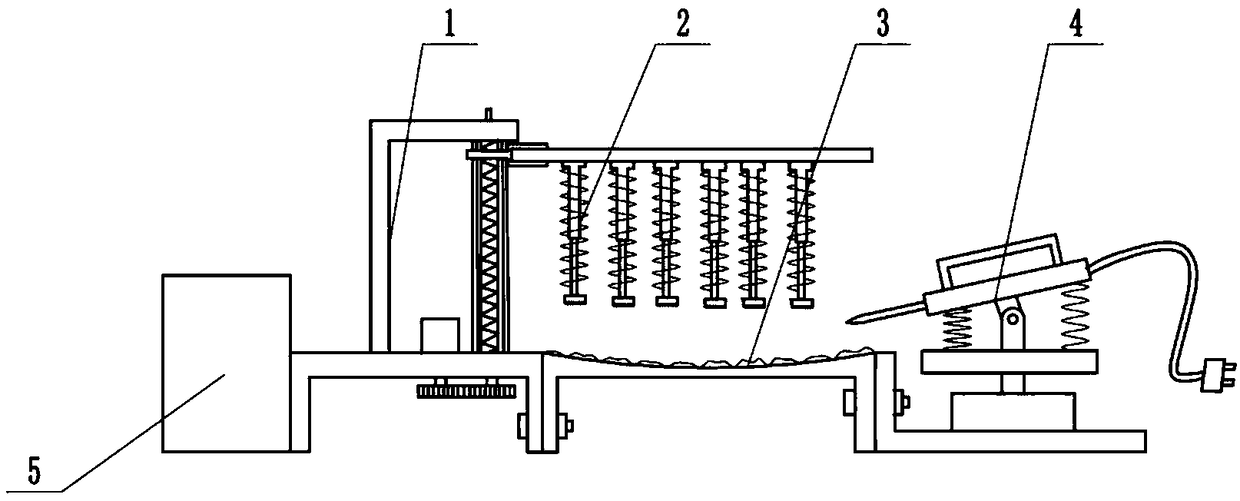

[0019] An oyster prying device is composed of a lifting device 1, an upper fixing device 2, a lower fixing device 3, a prying device 4 and a console 5. The lifting device 1 is fixed on the ground, and the upper fixing device The device 2 is installed on the upper side of the lifting device 1, the lower fixing device 3 is installed on the lower side of the lifting device 1, the prying device 4 is installed on one end of the lower fixing device 3, and the console 5 is placed on On one side of the lifting device 1, the output end of the console 5 is connected with the input end of the lifting device 1 and the input end of the prying device 4 respectively.

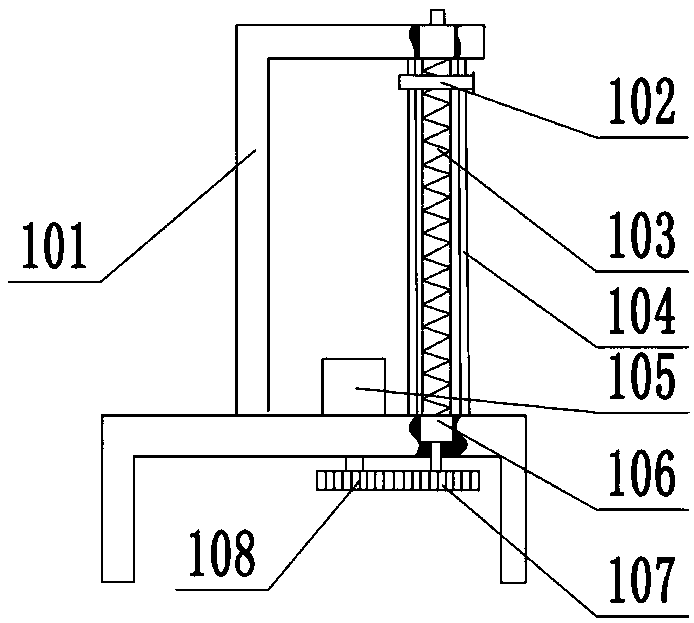

[0020] The lifting device 1 is composed of a lifting frame 101, a slide block 102, a lead screw 103, a cylindrical rod 104, a motor 105, a bearing 106, a screw gear 107 and a motor gear 108, and the lifting frame 101 is fixed on the ground Above, the motor 105 is fixed on the upper surface of the lower end of the lifting frame...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap