Radiator core assembly machine

A technology for assembly machines and radiators, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as aluminum corrosion, radiator deformation, and poor corrosion resistance, and achieve a firm assembly process, prevent damage, and ensure performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

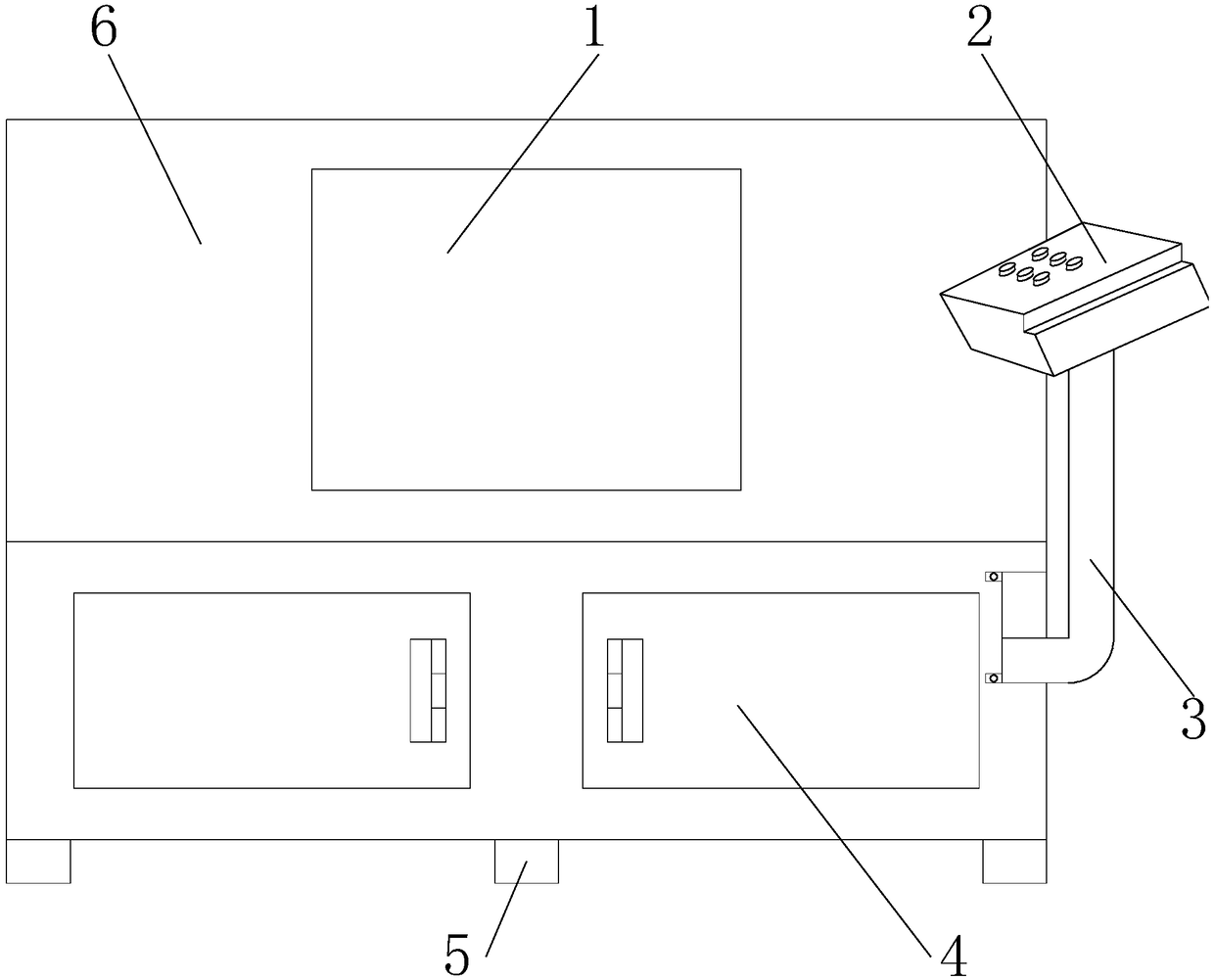

[0025] see Figure 1-Figure 6 , the present invention provides radiator core assembly machine, its structure includes window 1, manipulator 2, support rod 3, box door 4, support foot 5, assembly host 6, described window 1 is embedded in the upper end of the front surface of assembly host 6, The lower surface of the manipulator 2 is welded to the upper end of the support rod 3, and the lower end of the support rod 3 is hinged to the right side of the front surface of the assembly host 6. There are two doors 4 installed on the lower end of the front surface of the assembly host 6. The upper end of the support leg 5 is welded to the lower surface of the assembly host 6, and the assembly host 6 is electrically connected to the manipulator 2 through wires.

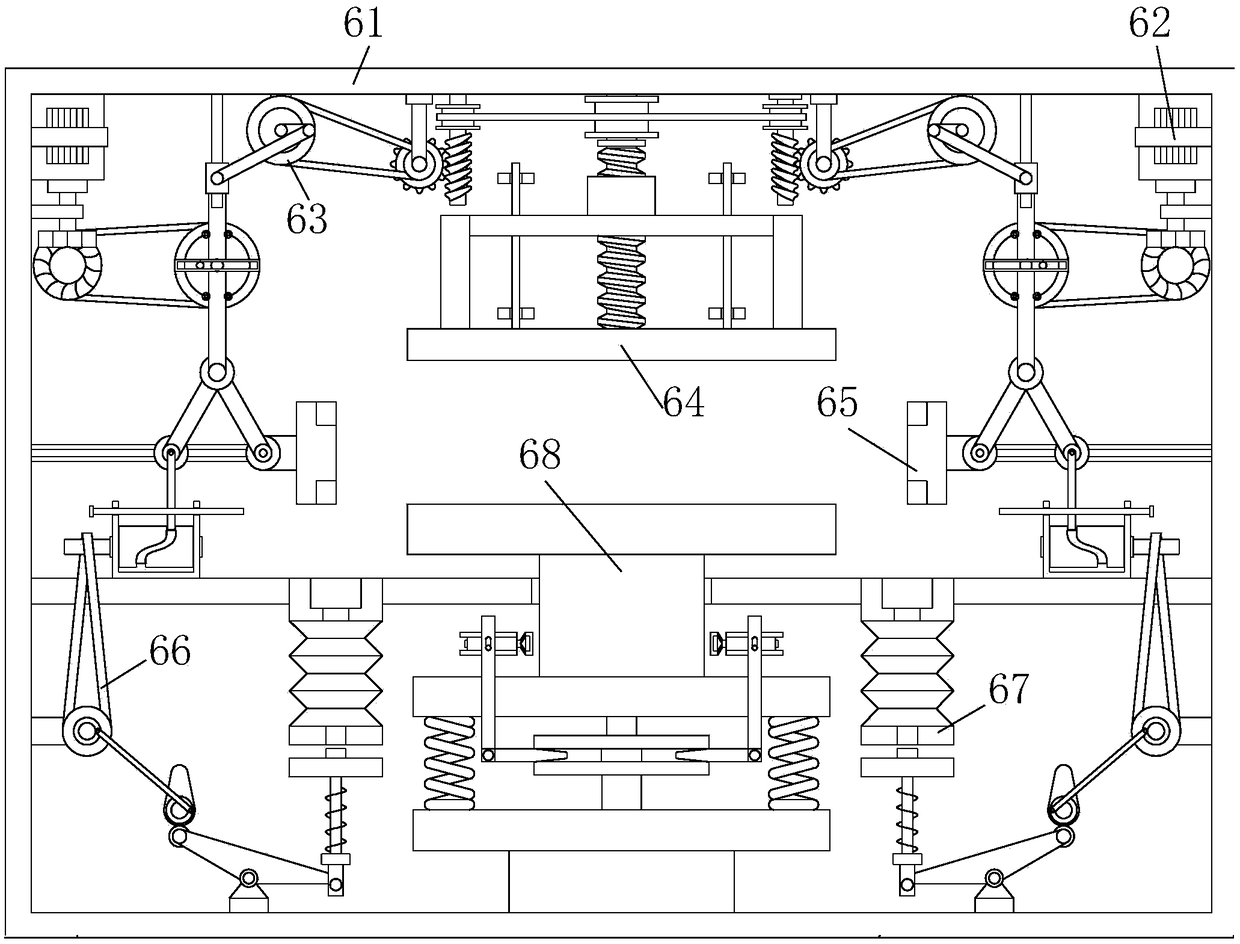

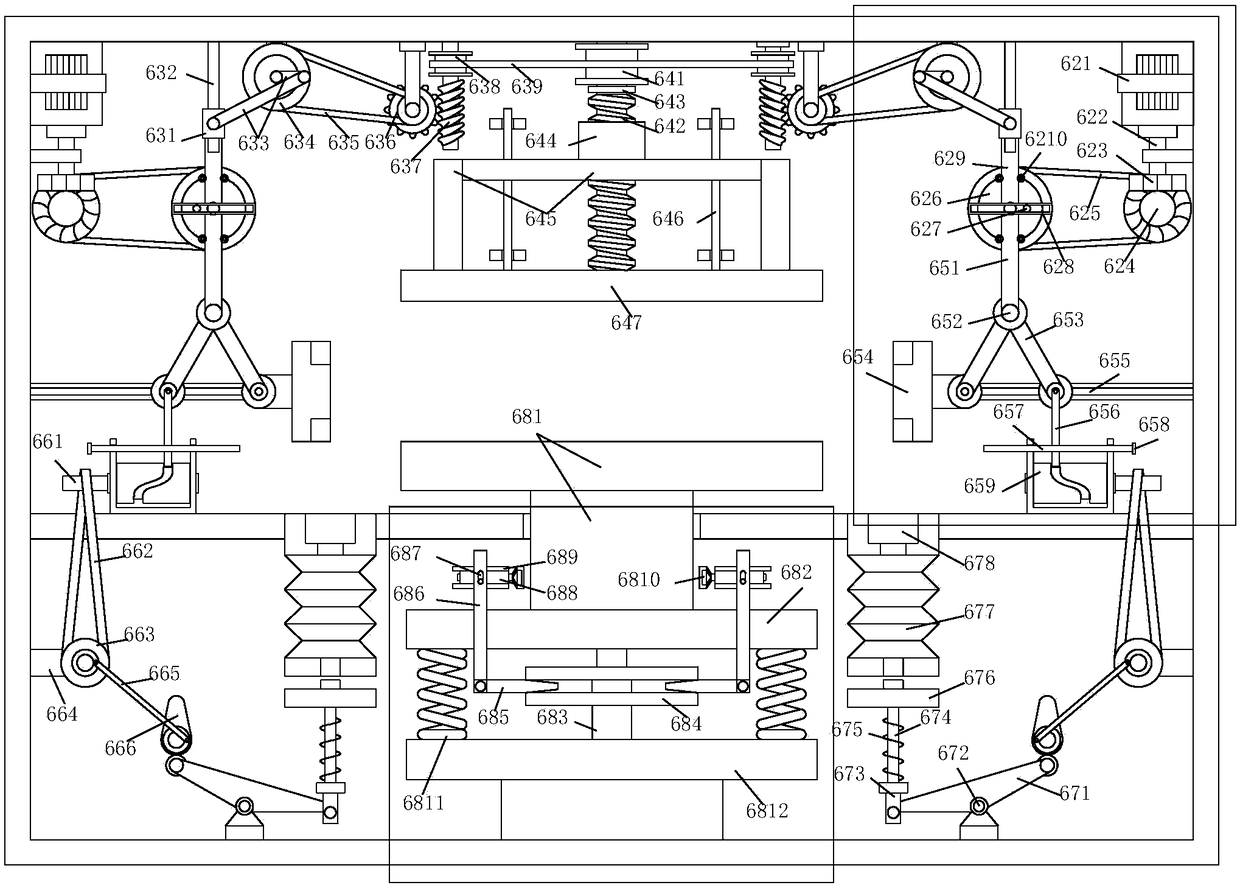

[0026] The assembly host 6 is provided with a host casing 61, a power mechanism 62, a drive mechanism 63, a flattening mechanism 64, a nesting mechanism 65, a transmission mechanism 66, a blast cooling mechanism 67, and a reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com