Manipulator, and mounting structure of reducer synchronous wheel assembly, wrist and forearm arm casting

A technology of mechanical arms and manipulators, applied in the direction of manipulators, program-controlled manipulators, assembly machines, etc., can solve problems such as set-up, achieve the effect of increasing stability and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

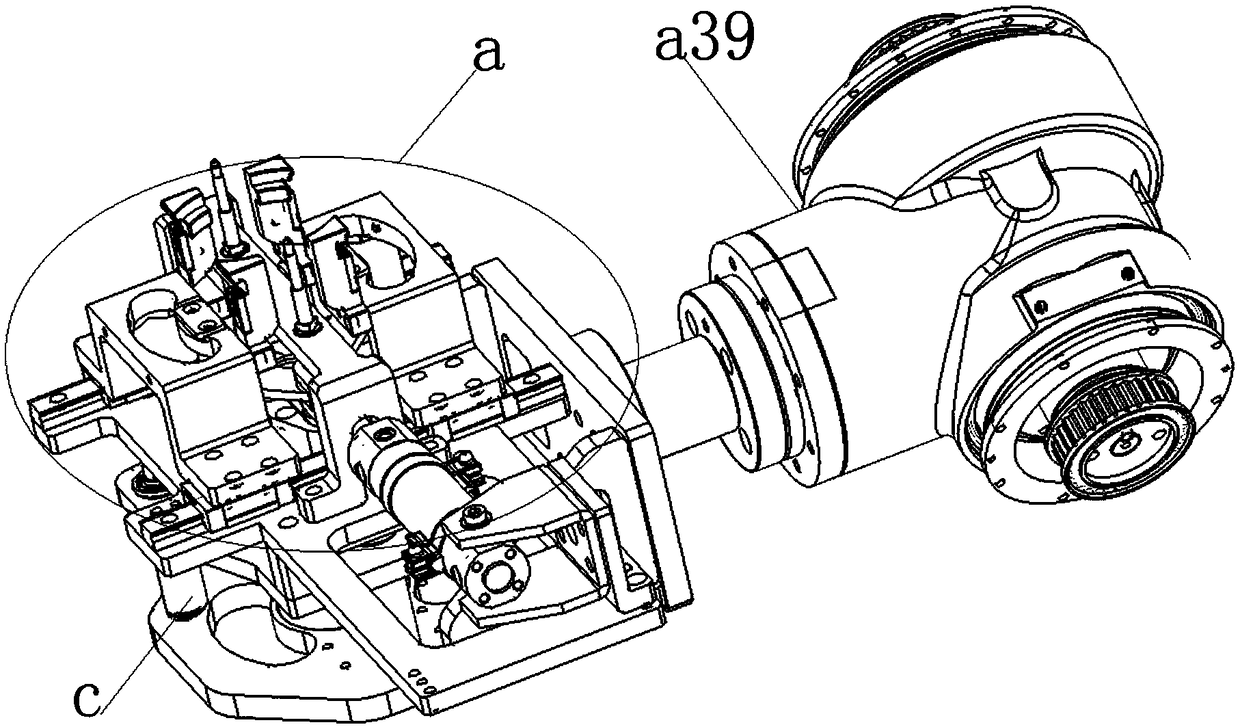

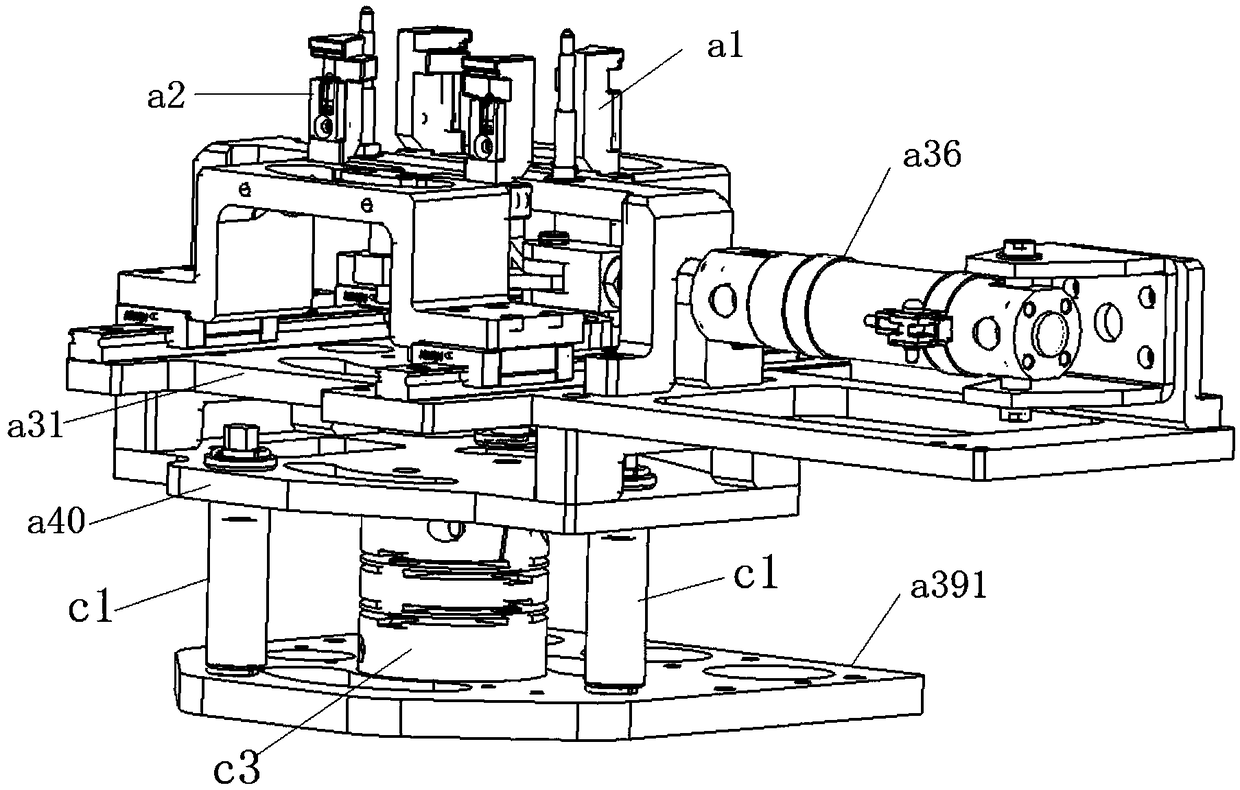

[0058] This embodiment provides a manipulator, such as figure 1 and figure 2 As shown, it includes a mechanical arm a39, a clamping structure a and an adjustment mechanism c.

[0059] Among them, the base a391 is fixed on the mechanical arm a39, and the adjustment mechanism c elastically connects the base a391 to the clamping structure a. When the clamping structure a is subjected to an external reverse force, the adjustment mechanism c can adjust the clamping structure position, and then adjust the position of the clamping structure to clamp the part to be transferred, so that the part to be transferred is coaxially sleeved on the alignment axis d2.

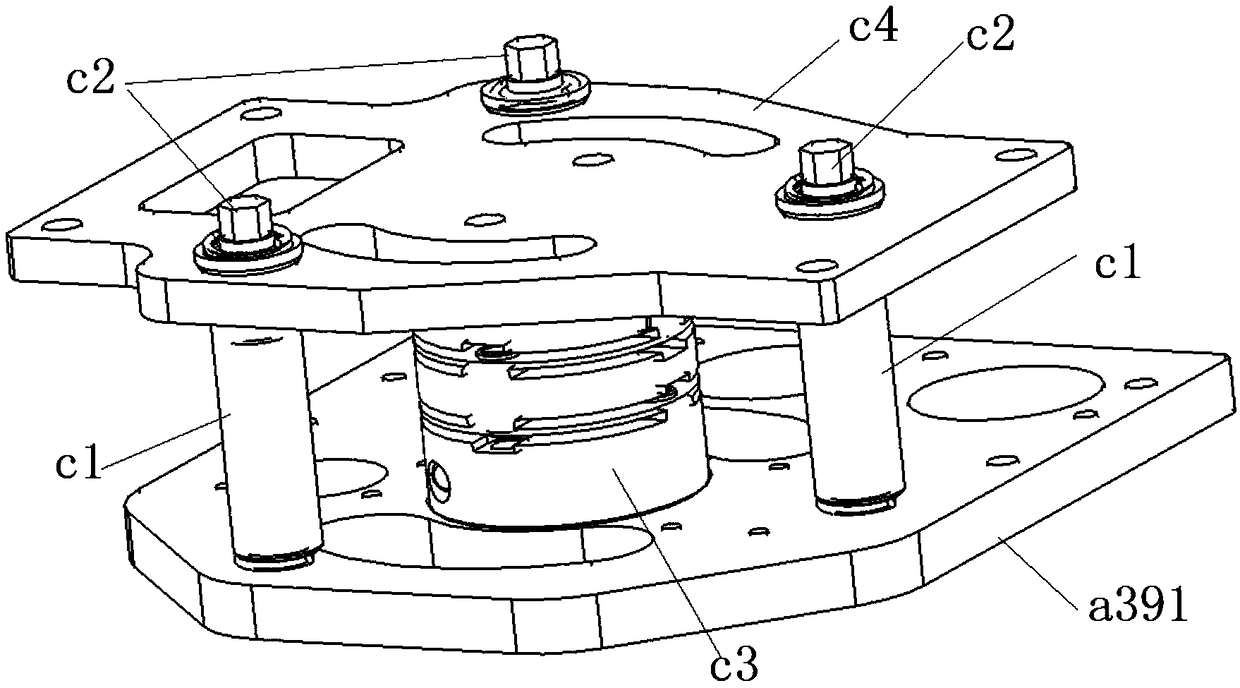

[0060] Such as figure 2 , image 3 as well as Figure 4 As shown, the adjustment mechanism c includes three elastic pieces c1, three support pieces c2 and one elastic body c3. Each elastic member c1 can be selected as a spring, and the springs are sleeved on the supporting member c2 one by one, and the two ends of the spr...

Embodiment 2

[0098] This embodiment provides a manipulator, compared with the manipulator provided in Embodiment 1, the difference is that:

[0099] The spring plunger in the clamping structure in the manipulator in this embodiment can be replaced by a spring, or other existing elastic buffers, and the number of elastic buffers a16 can be one, two, three, four, etc. etc. The specific number of settings depends on actual needs. Alternatively, the elastic buffer a16 may not be provided, and only the first groove is used to clamp the part to be transferred.

[0100] As a modification, the third clamping part a13 can also be independent of the second clamping part a12, and a first groove recessed from outside to inside is provided on the outer side walls of the first chuck body a1 and the second chuck body a2. The first groove can also be replaced by other structures, such as protrusions, correspondingly, a groove is provided on the wall surface of the inner chamber of the part to be transfer...

Embodiment 3

[0103] This embodiment provides a manipulator, compared with the manipulator provided in Embodiment 1 or Embodiment 2, the difference is that:

[0104]The driving mechanism a3 in the clamping structure in the manipulator can be replaced by other driving mechanisms, such as setting the clamping cylinder separately, fixing the first mounting plate a351 and the second mounting plate a352 respectively on the two sliding parts of the clamping cylinder , so as to change the distance between the first chuck body a1 and the second chuck body a2.

[0105] As a modification, only one set of the first chuck body a1 and the second chuck body can be provided. Correspondingly, the above-mentioned first mounting plate a351 and the second mounting plate a352 are not required, and the first chuck body a1 and the second mounting plate a352 are directly connected to each other. The second chuck body a2 is respectively fixed on a slider a34. Alternatively, multiple sets of the first chuck body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com