Loading device for cotton sliver sticking equipment

A technology of sliver and equipment, applied in the field of automation, can solve the problems of breaking, unstable cotton drawing speed, unstable sliver fixing, etc., and achieve the effect of stable circumferential positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

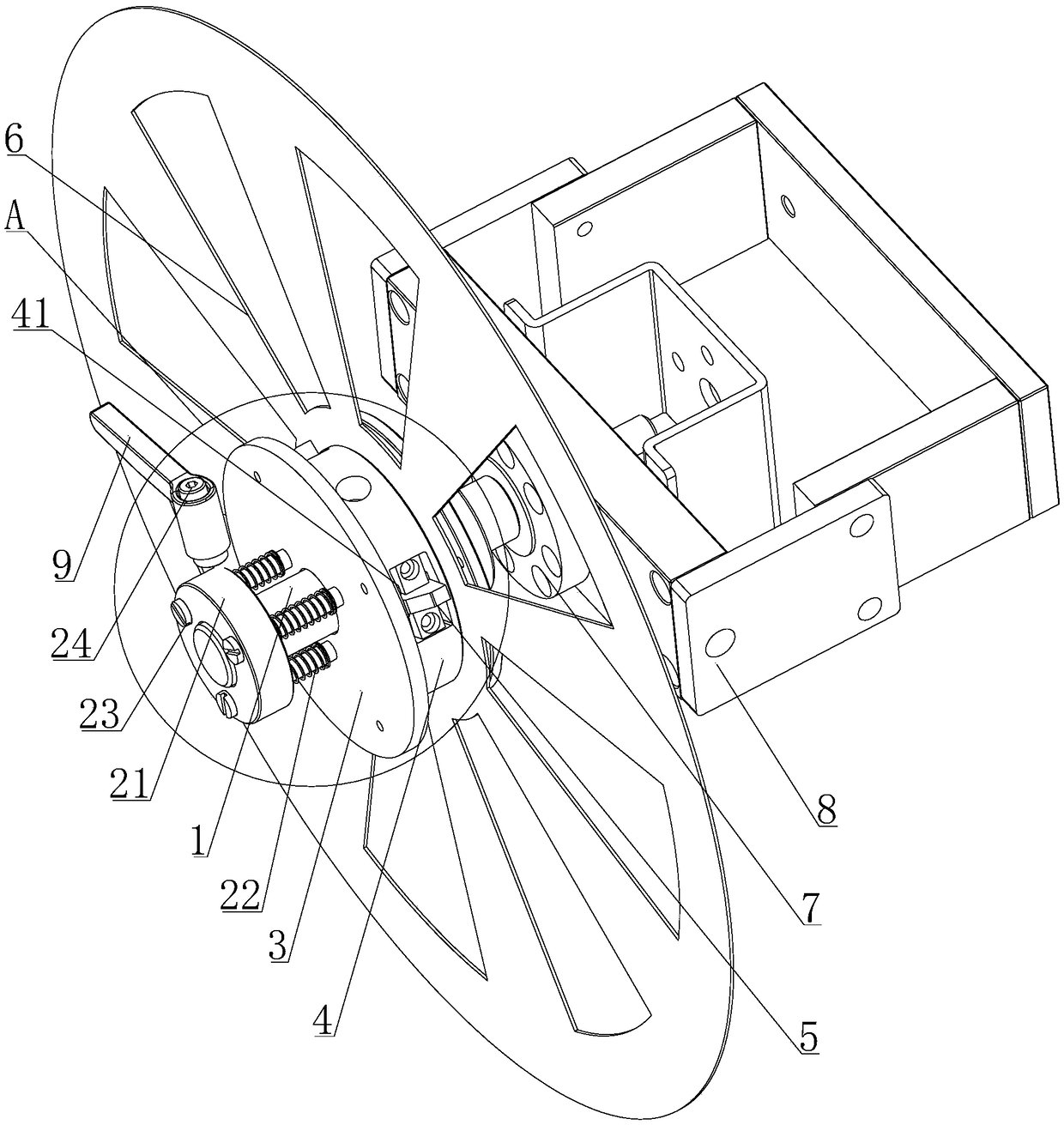

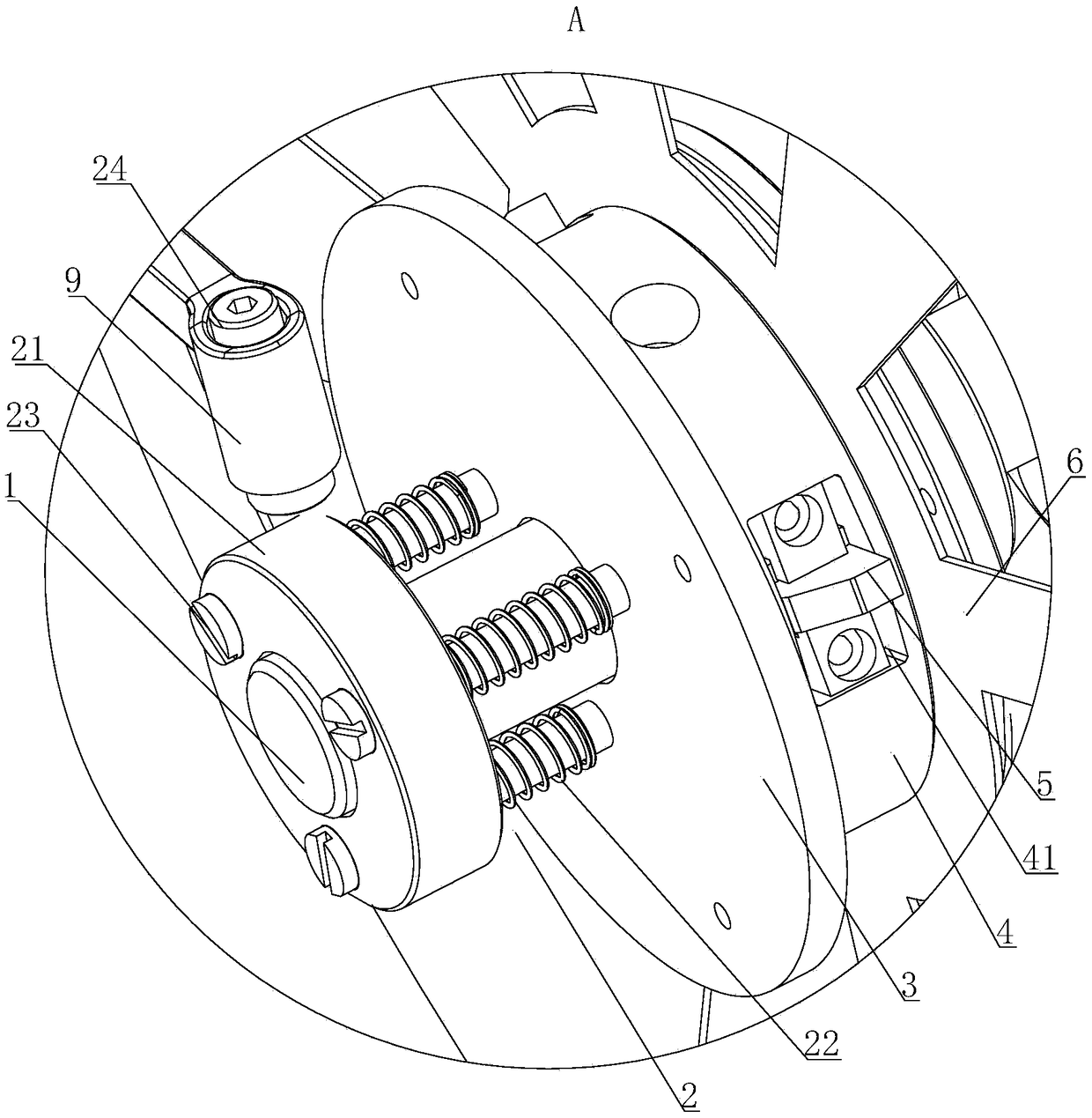

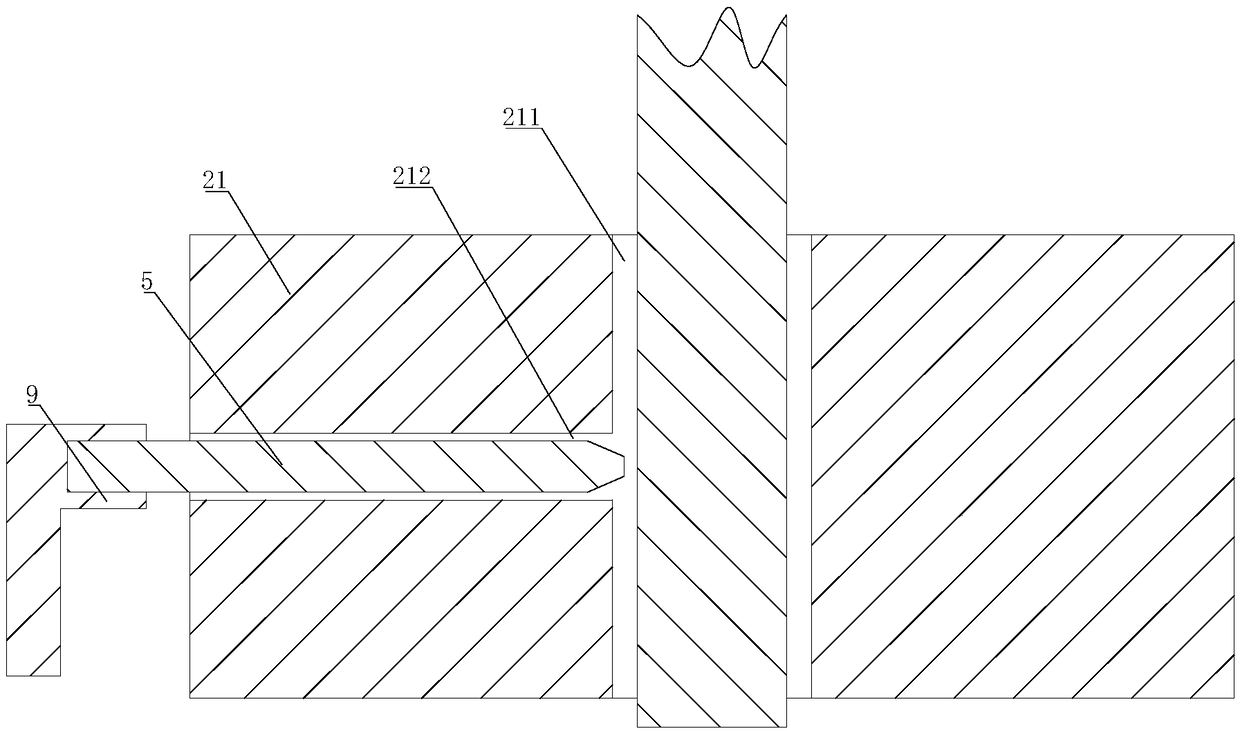

[0020] The invention provides a loading device for sliver pasting equipment, which includes a rotating shaft 1, a pretensioning device 2, a pressure plate 3, a cotton disc sleeve 4, a plurality of pogo pins 5, a cotton disc 6, a one-way bearing 7 and The magnetic damper 8, the preload device 2, the pressure plate 3, the cotton disc sleeve 4, the cotton disc 6, the one-way bearing 7 and the magnetic damper 8 are sequentially set on the On the rotating shaft 1, the cotton disc cover 4 is fixedly connected with the cotton disc 6, a plurality of positioning holes 41 are opened on the side surface of the cotton disc cover 4, and the spring thimble 5 is fixedly arranged on the positioning Inside the hole 41;

[0021] The one-way bearing 7 is set to prevent the reverse rotation of the rotating shaft 1 from being affected, thereby affecting the cotton sticking effect of the sliver, and the magnetic damper 8 is set to prevent the rotating shaft 1 from rotating at will, thereby affectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com