Composite type car all built-in elevator state sensor

A state sensor and composite technology, applied in the field of elevator sensors, can solve the problems of increasing system implementation cost, difficult implementation of size, large size structure, etc., and achieve the effect of high cost performance, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

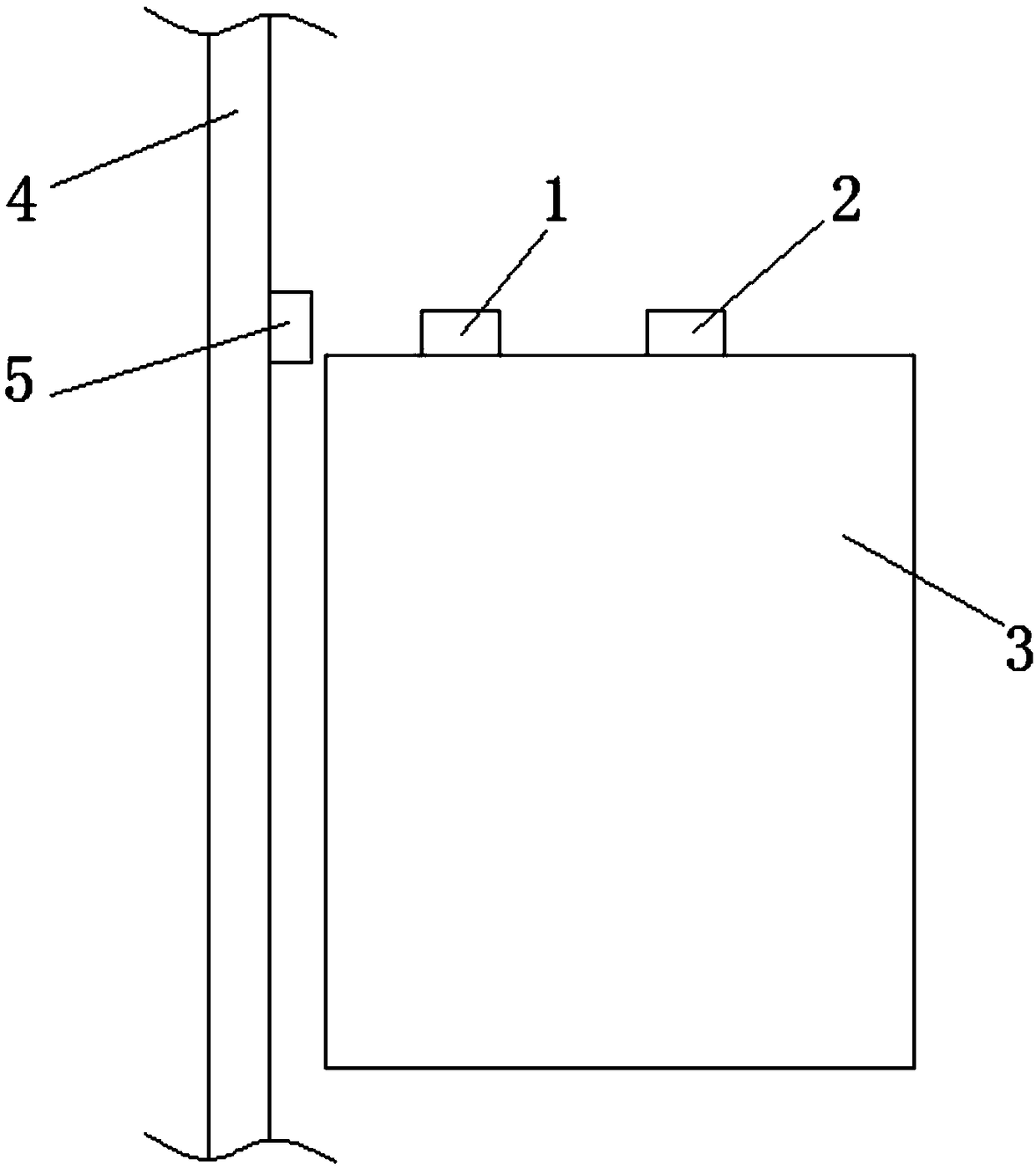

[0020] see figure 1 , the present invention provides a technical solution: a composite car with a built-in elevator state sensor, including a magnetic sensor 1 and an acceleration sensor 2, the magnetic sensor 1 and the acceleration sensor 2 are both arranged on the top of the outer wall of the elevator 3 , The guide rail 4 used in conjunction with the elevator 3 is equipped with a magnetic isolation plate 5 .

[0021] Its working principle includes the following steps:

[0022] S1. When the elevator 3 is leveling, the magnetic sensor 1 is aligned with the magnetic isolation plate 5, and the sensor is triggered to detect the leveling;

[0023] S2. The acceleration sensor 2 collects the acceleration state of the operation of the elevator 3 to determine the direction of the elevator 3 operation, and can also measure parameters such as the running speed and the running distance of the elevator 3 based on the algorithm;

[0024] S3. When the magnetic sensor 1 is aligned with the...

Embodiment 2

[0026] see figure 1 , the present invention provides a technical solution: a composite car with a built-in elevator state sensor, including a photoelectric sensor 1 and an acceleration sensor 2, and the photoelectric sensor 1 and the acceleration sensor 2 are both arranged on the top of the outer wall of the elevator 3 , a light-shielding plate 5 is installed on the guide rail 4 used in conjunction with the elevator 3 .

[0027] Its working principle includes the following steps:

[0028] S1. When the elevator 3 is leveling, the photoelectric sensor 1 is aligned with the light barrier 5, and the sensor is triggered to detect the leveling;

[0029] S2. The acceleration sensor 2 collects the acceleration state of the operation of the elevator 3 to determine the direction of the elevator 3 operation, and can also measure parameters such as the running speed and the running distance of the elevator 3 based on the algorithm;

[0030] S3. When the photoelectric sensor 1 is aligned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com