Adit drawing ore-pass with reinforcing well wall

A technology of mine sliding shaft and flat tunnel, which is used in mine/tunnel ventilation, ground mining, mining equipment, etc., can solve the problems of high ore drawing impact, wear of sliding shaft wall, shaft wall damage, etc., to achieve high safety performance, lightening Abrasion, good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

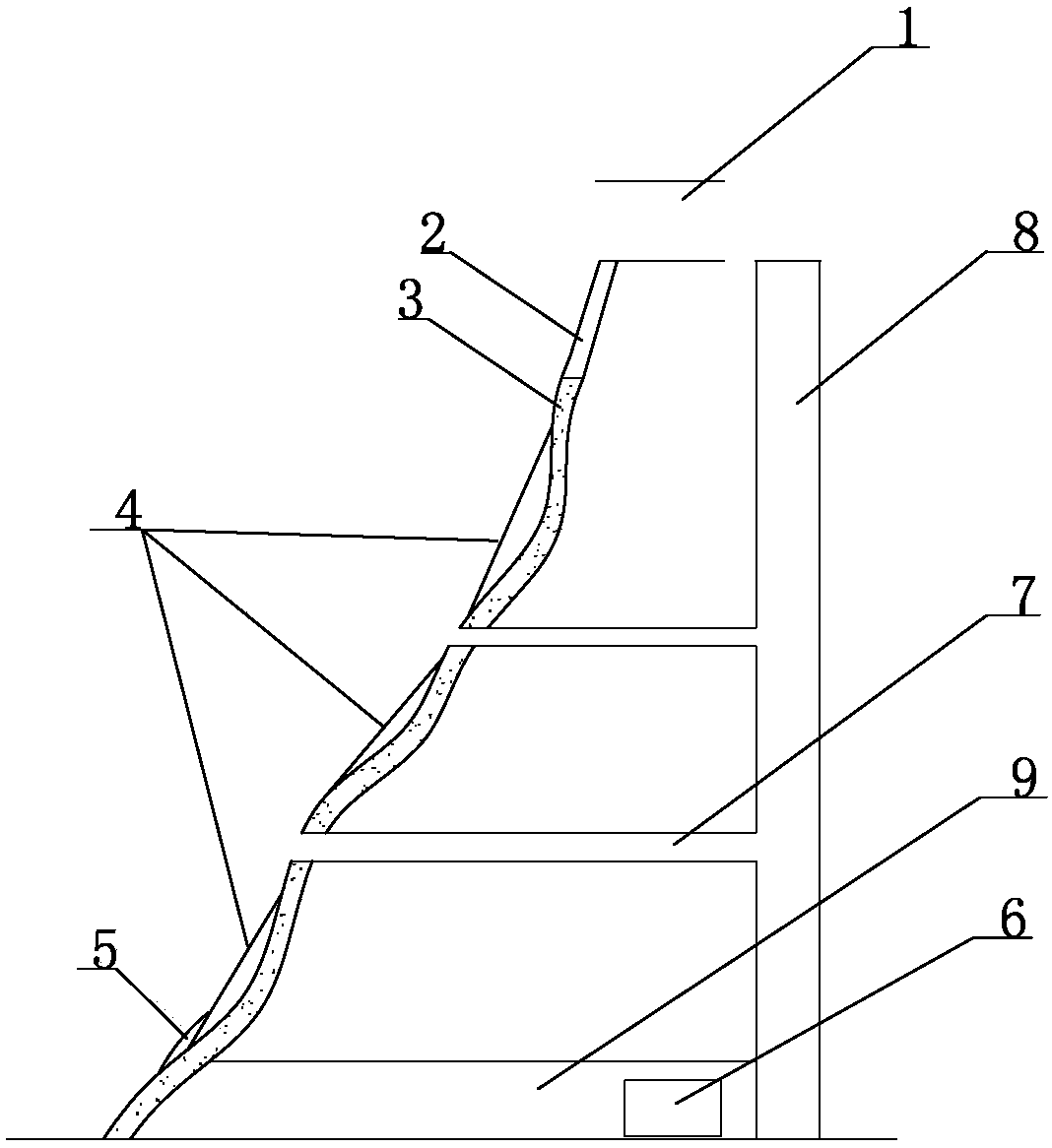

[0012] A kind of adit ore-drawing shaft with reinforced shaft wall, such as figure 1 As shown, it includes an adit 1, an ore-drawing chute and a vertical shaft 8. The adit 1 is connected to the top of the auxiliary slope 2, and the bottom of the auxiliary slope 2 is connected to the ore-drawing chute shaft wall 3, and a loop is set between the vertical shaft 8 and the ore-drawing chute shaft wall 3. Wind roadway 7, manganese steel plate 4 is set on the ore-drawing chute shaft wall 3, and the bottom of ore-drawing chute and shaft 8 is communicated by passage 9, and transport vehicle 6 is provided in passage 9. A curved steel plate 5 is arranged at the joint between the manganese steel plate 4 and the shaft wall 3 of the ore-drawing chute.

[0013] The ore is directly poured into the ore-drawing chute from the adit 1, and reaches the bottom of the shaft through the auxiliary slope 2 and the ore-drawing chute shaft wall 3. The well wall 3 of the ore-drawing chute is generally no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com