Device for combined blending reinforcement of solid rocket scramjet engine

A technology of scramjet and solid rockets, which is applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., to achieve the effect of improving secondary combustion efficiency and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

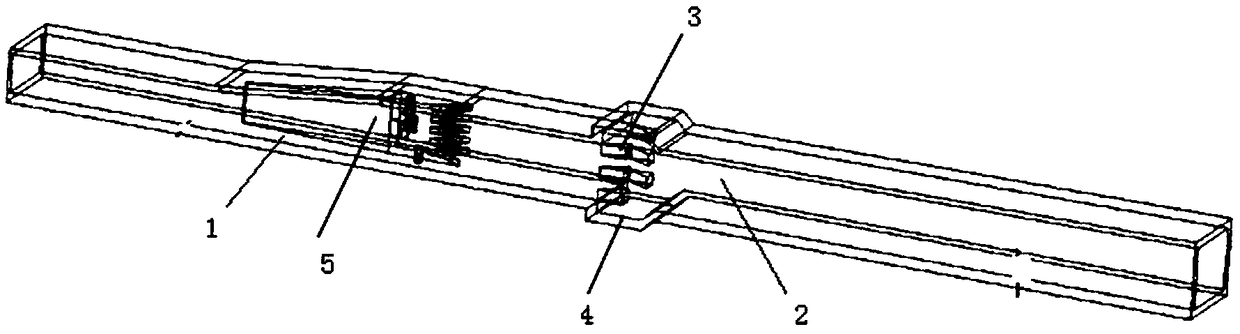

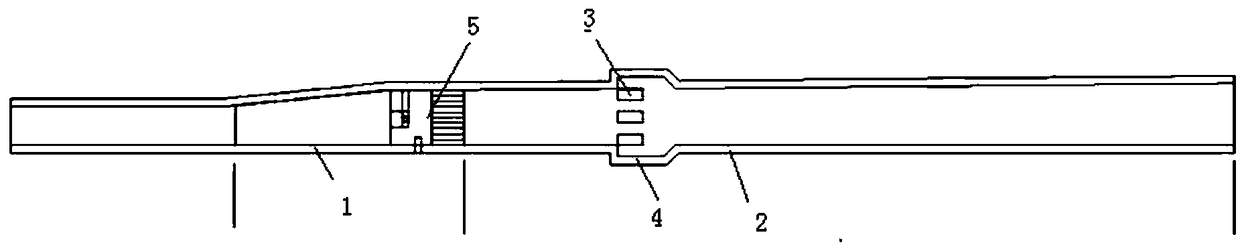

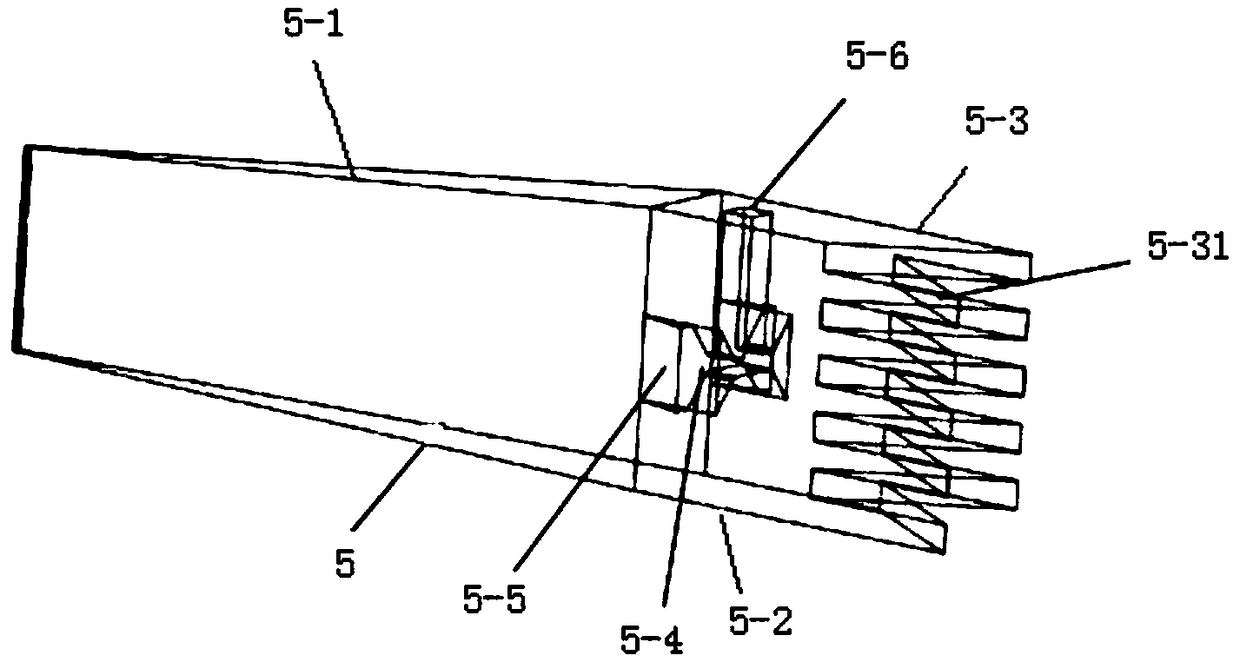

[0021] A kind of solid rocket scramjet of the present invention, as figure 1 and 2 As shown, it includes the isolation section 1 and the combustion chamber 2 which are connected front and back. On the left and right side walls in the combustion chamber 2, a plurality of turbulence devices 3 are arranged side by side in the vertical direction at intervals, and a gas flow is formed between adjacent turbulence devices 3. Runner: The upper and lower walls of the combustion chamber 2 corresponding to the position where the spoiler 3 is installed protrude outwards to form an outwardly convex concave cavity 4 relative to the combustion chamber 2 . The spoiler 3 is a wedge, and the tip of the wedge faces to the front of the combustion chamber 2 . In the actual design, three turbulence devices 3 can be arranged on each side, and they are evenly spaced. The turbulence device 3 added to the combustion chamber is combined with the concave cavity 2. The area of the combustion chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com