Exhaust valve plate assembly and compressor

A technology for exhaust valves and compressors, which is applied to pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems of high impact force at the exhaust hole, prolong service life, improve versatility, reduce The effect of small shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

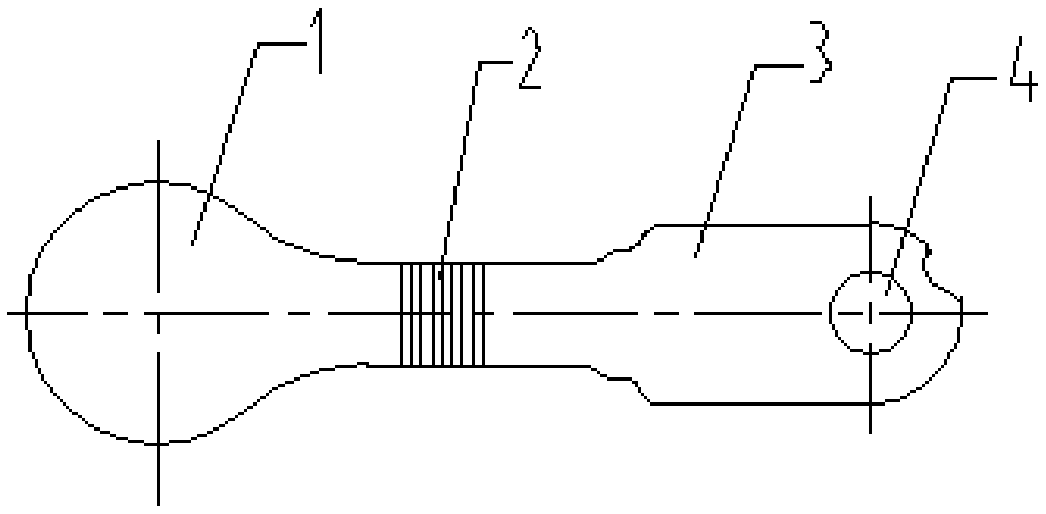

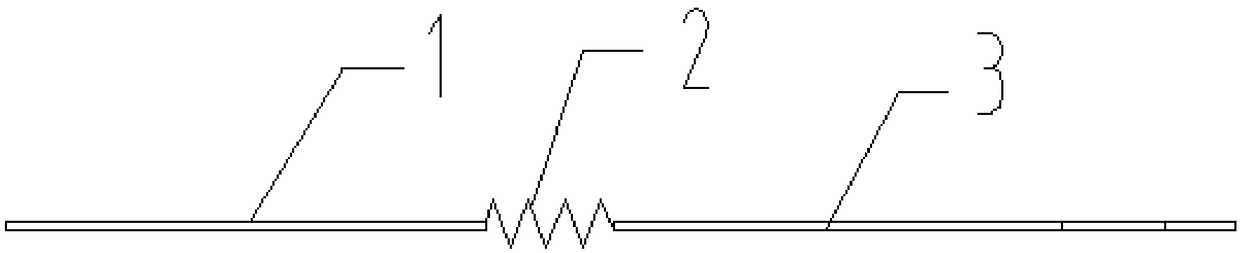

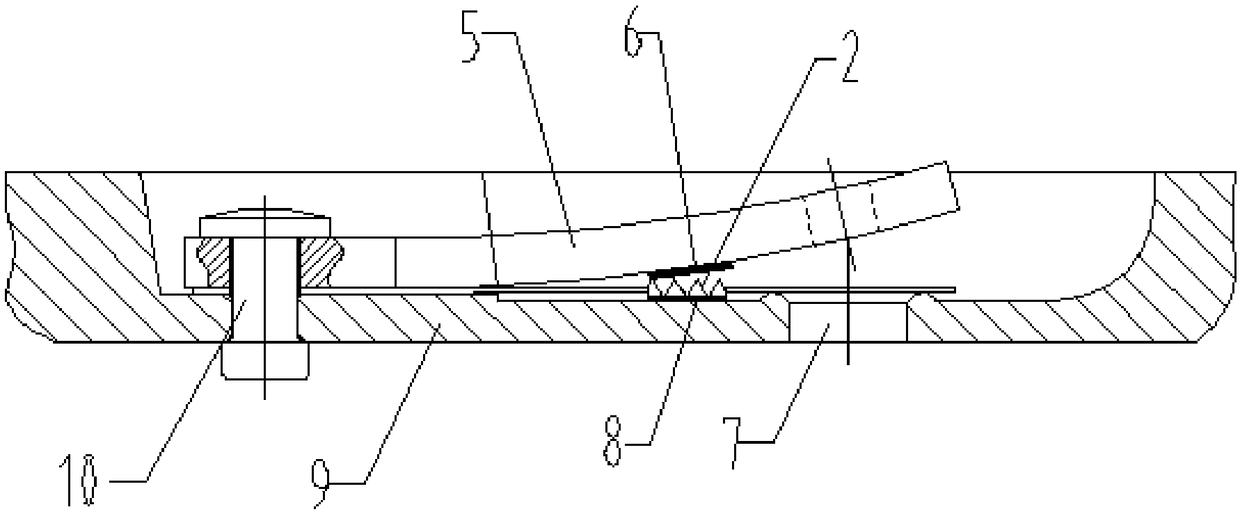

[0036] Such as Figure 1-4 As shown, an exhaust valve assembly of the present invention includes:

[0037] The exhaust valve plate is adapted to be connected to the first object with the exhaust port 7, and when the exhaust at the exhaust port 7 ends, the exhaust valve plate will quickly close toward the direction movement;

[0038] Buffer, when the exhaust valve plate is closed, its buffer force acts on the exhaust valve plate, and the direction of the buffer force is opposite to the direction of the reset force, and the magnitude of the buffer force is smaller than the reset force the size of.

[0039] The exhaust valve plate assembly with the above structure, due to the function of the restoring force, can have a high speed when the exhaust valve plate is initially closed, and the closing speed is not delayed. At the same time, the function of the buffer can make the exhaust valve plate close quickly. Rapidly becomes smaller, reducing the impact of the exhaust valve plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com