Automotive clutch control system

A clutch control and clutch controller technology, applied in the direction of clutch, mechanical equipment, etc., can solve the problems of driver fatigue, clutch damage, and great effort, so as to reduce wear, avoid malfunction, and avoid ablation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

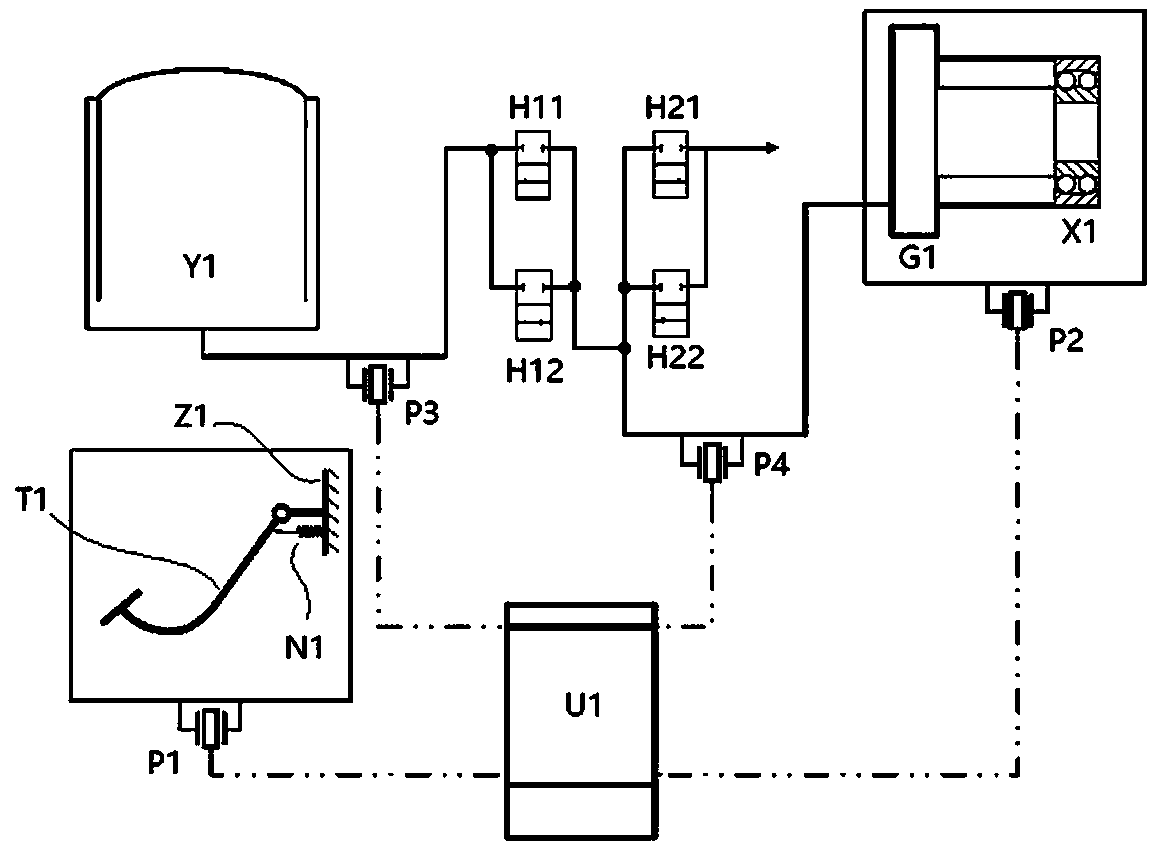

[0013] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all represent the relationship between and, and the English letters in the present invention are case-sensitive.

[0014] like figure 1 As shown, a vehicle clutch control system provided by the embodiment of the present invention includes a clutch, a pedal base Z1, and a clutch pedal T1 pivotally arranged on the pedal base Z1. The pedal return part N1 of the position is characterized in that it also includes an air reservoir Y1, a clutch controller U1, a clutch execution cylinder G1, a fast-forward valve H11, a slow-forward valve H12, a quick-exhaust valve H21, and a slow-exhaust valve H22;

[0015] The clutch executio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com