Modular duplex adjusting valve

A regulating valve, combined technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problem that the valve core can not solve the sealing ring compensation well, so as to ensure the service life, solve the inconvenient operation, pressure resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

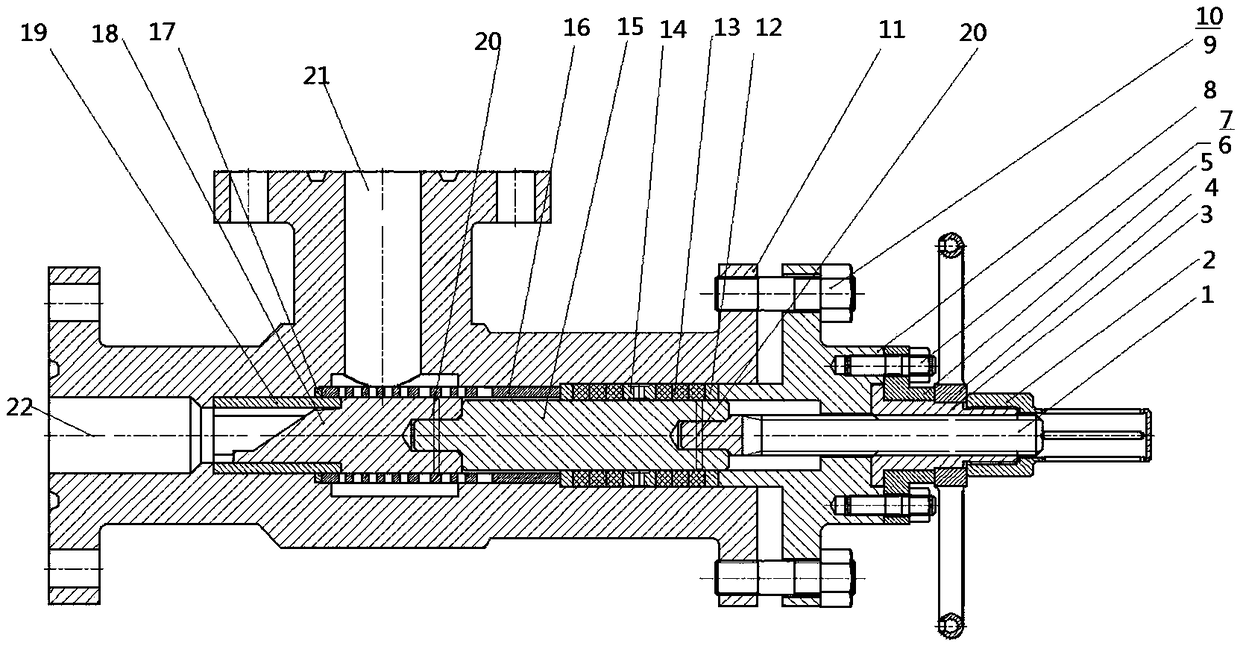

[0010] As shown in the figure, 1. Upper valve stem, 2. Assembled cap, 3. Valve stem nut, 4. Handwheel, 5. Bonnet, 6. Bolt, 7. Nut, 8. Packing gland, 9. Nut, 10. Bolt, 11. Valve body, 12. Packing pressure ring, 13. Composite packing, 14. Packing spacer, 15. Lower valve stem, 16. Valve cage, 17. Gasket, 18. Valve core, 19. Lining Cover, 20, pin, 21, outlet, 22, inlet; the upper direction of the cylindrical valve body is provided with inlet and outlet, and the direction of inlet and outlet is vertical, and when the inlet is at the left end of the horizontal direction, the outlet direction is upward; the same axis of the inlet There is a cylindrical valve seat on the straight line, that is, the center of the cylinder is used to install the valve seat. The valve seat is in the shape of a cage. The valve cage is a bar with gaps evenly distributed on the wall of the cylinder. , the spool is a round rod plugged into the valve seat; the first valve stem is fixed on the right end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com