A heat tracing pipeline efficiency-enhancing installation device

A technology for installing device and heat tracing pipe, which is applied in the direction of pipe heating/cooling, pipe/pipe joint/pipe fitting, mechanical equipment, etc., which can solve the problem of unsatisfactory heat tracing effect, compression of the space around the main pipe, and difficulty in fixing long-distance heat tracing pipes, etc. problems, to reduce workload, improve installation efficiency, and avoid classification work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

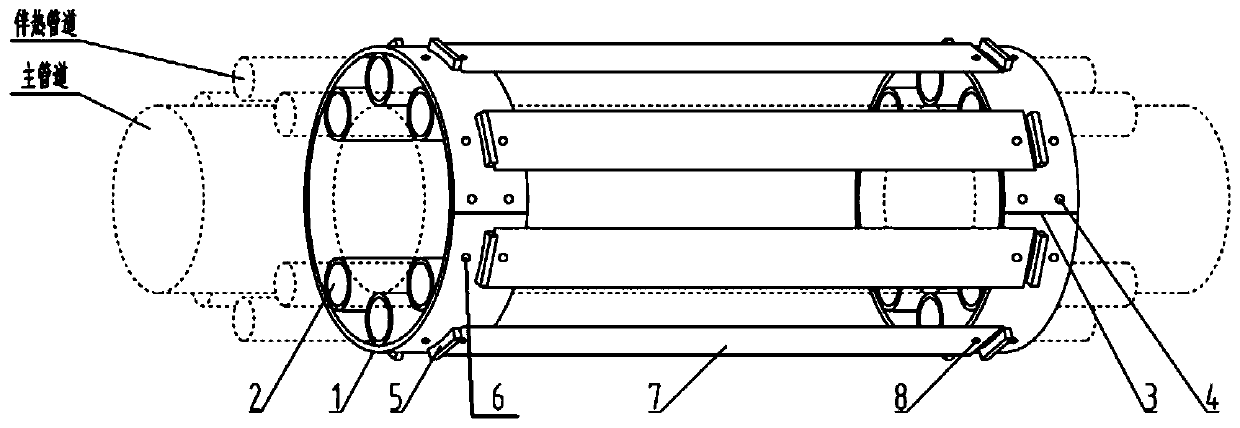

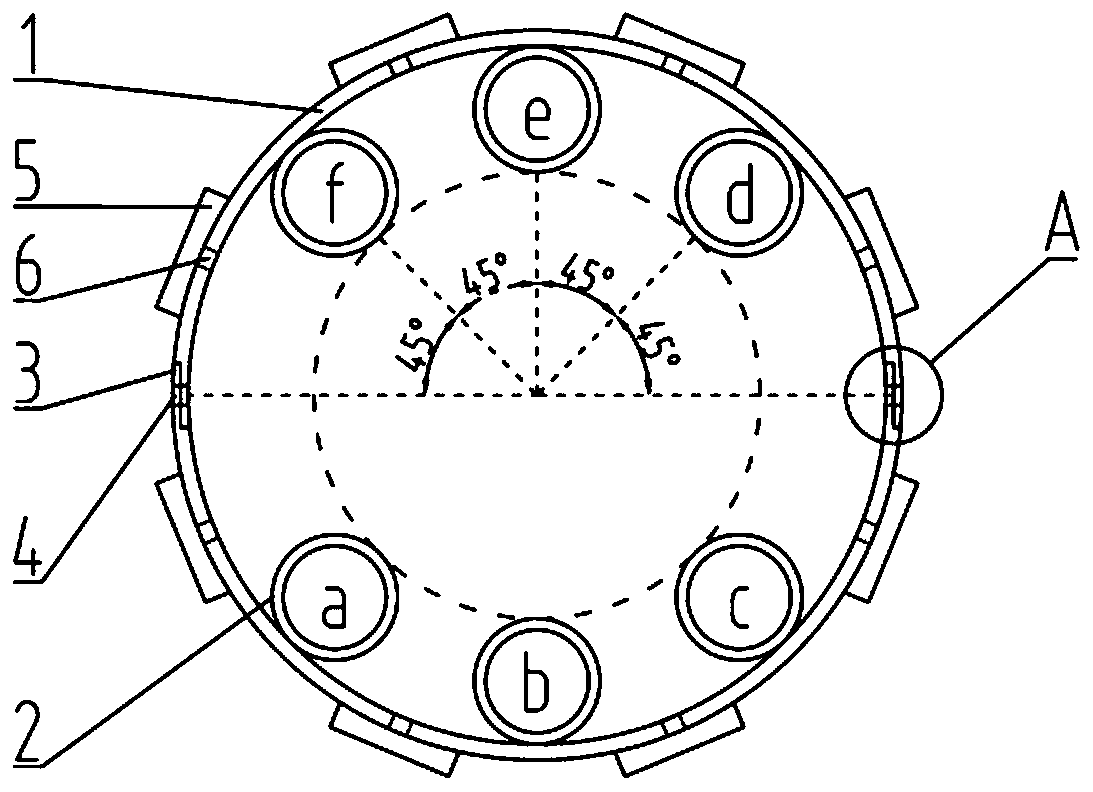

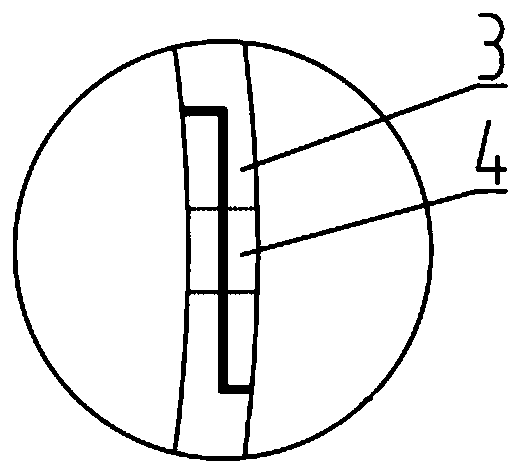

[0023] refer to Figure 1 to Figure 3 , the heat tracing pipe efficiency installation device according to the present invention includes a thermal insulation layer and a number of annular locators 1 distributed sequentially along the main pipe, wherein each annular locator 1 is socketed on the main pipe, and the inner wall of each annular locator 1 There is a heat tracing tube positioning cylinder 2 for the passage of the heat tracing pipe on the top, and a number of inner braces 7 are connected between two adjacent annular positioners 1, and all inner braces between two adjacent annular positioners 1 The plates 7 are distributed along the circumferential direction, and each annular positioner 1 and each inner support plate 7 are wrapped in the insulation layer, and a cavity structure is formed between the insulation layer and the main pipeline. Generally, there are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com