Method for improving fatigue life of swing arm structure

A technology of fatigue life and boom, which is applied in the field of boom structure evaluation and detection, can solve the problems of increased production cost and increased production time, and achieve the effect of improving fatigue life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the method for improving the fatigue life of the boom structure of the present invention will be described in more detail in conjunction with the schematic diagram, which shows the preferred embodiment of the present invention. It should be understood that those skilled in the art can modify the present invention described here and still realize the present invention. The advantageous effect of the invention. Therefore, the following description should be understood to be widely known to those skilled in the art, and not as a limitation to the present invention.

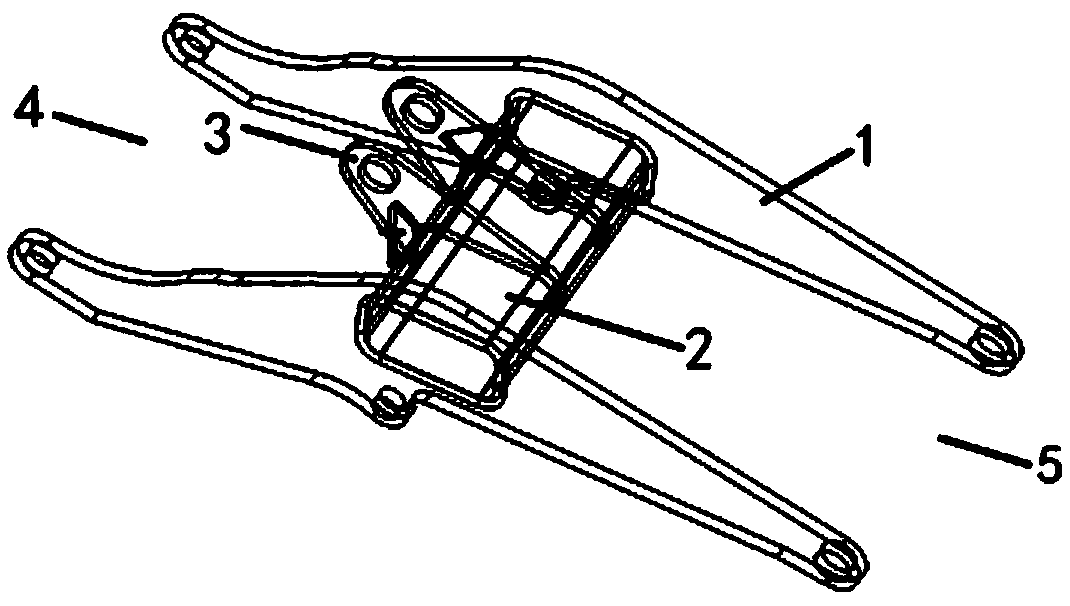

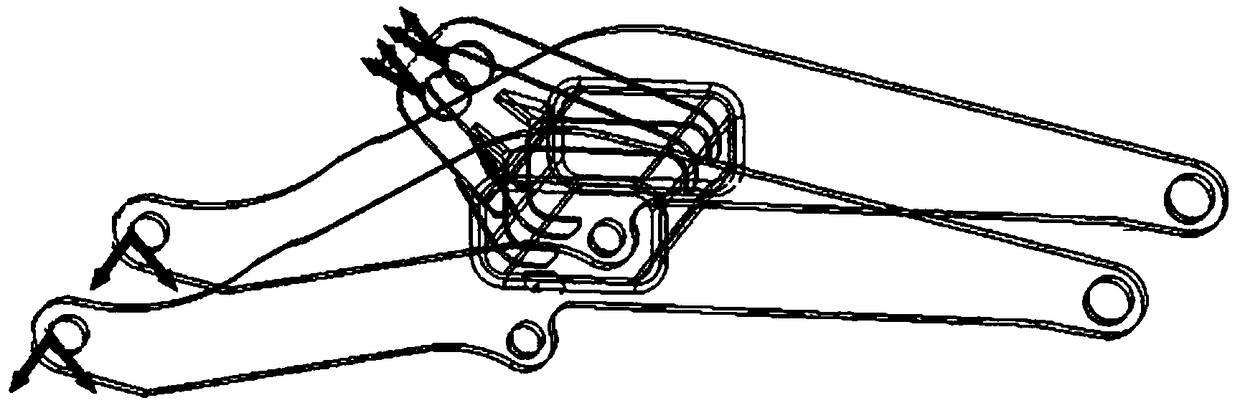

[0028] In this embodiment, take a certain model of boom welding as an example, such as figure 1 The boom structure shown is composed of a boom plate 1, a cross beam 2, a supporting plate and a rib plate welded together. The analysis shows that the welding seam between the boom and the beam 2 shows residual tensile stress in the welding seam after welding.

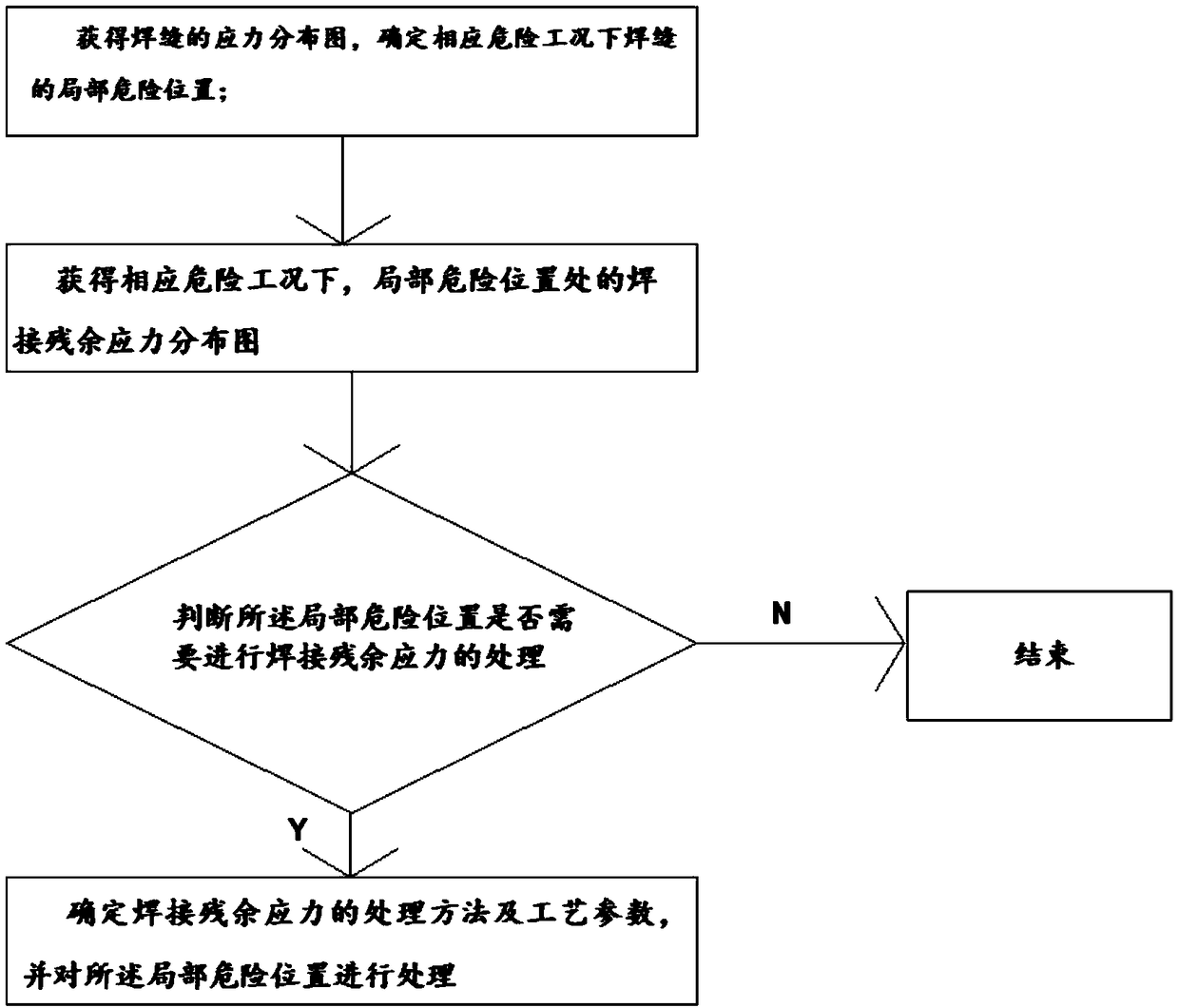

[0029] Such as figure 2 As shown, a me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap