On-line silk thread detection device and on-line detection method

A detection device and detection method technology, applied in the field of silk thread, can solve the problems of less sampling, waste products, and thread characteristics tending to the design value, etc., and achieve the effect of simple structure, stable mechanical characteristics, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

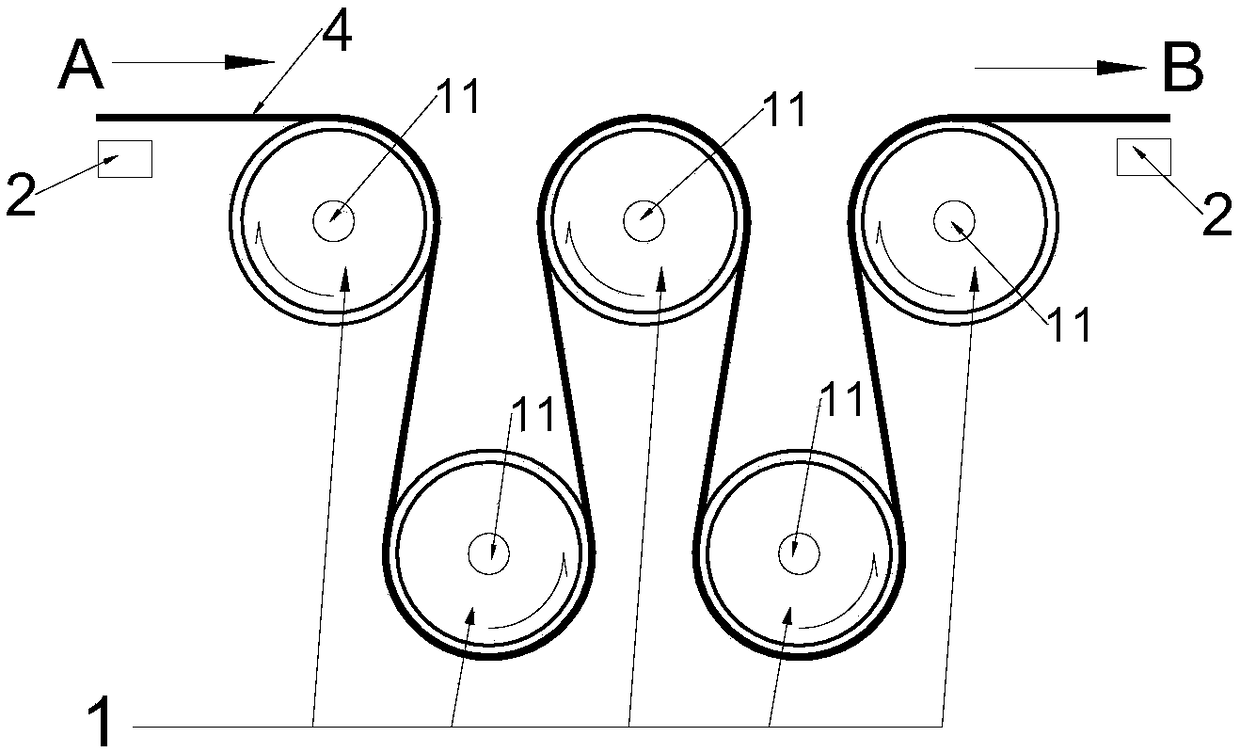

[0066] like figure 1 As shown, the silk thread to be tested is input from the input terminal A, wound around five power wheels 1, and then output from the output terminal B; the designed tensile force value of the tested silk thread is F t =50N.

[0067]In this embodiment, the five power wheels 1 are respectively provided with a damping system and provide stable damping torque. Under the action of the traction system (not shown in the figure), the wire runs from the input end A to the output end B, so that the tension value of the wire increases along the traveling direction of the wire. Control the tension value F of the silk thread input end through the movable pulley (not shown in the figure) carrying the counterweight a is 10N. There are 5 power wheels 1 in the present embodiment, through actual measurement data, each correlation coefficient Q imax >0.6, each correlation coefficient Q i Take 0.4 for both, and the tension variables provided to the silk by the five powe...

Embodiment 2

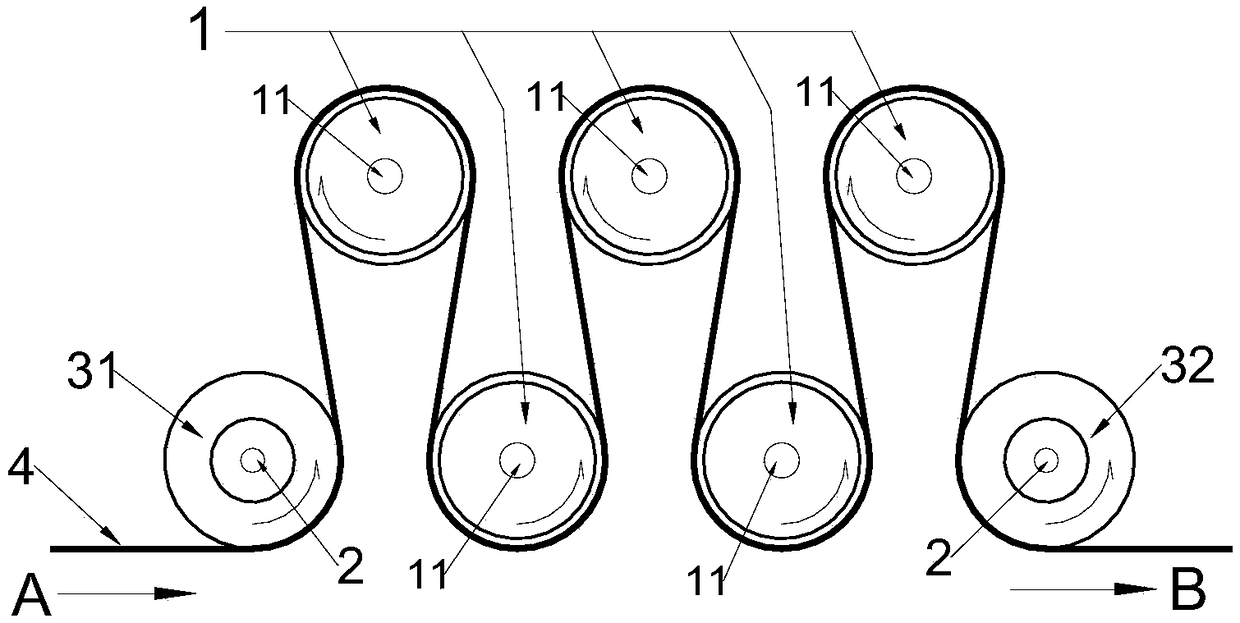

[0078] like figure 2 As shown, the wire to be detected is input by the first guide wheel 31 arranged at the input end A, passes through five power wheels 1, and is output by the second guide wheel 32 arranged at the output end B. The design resistance of the wire to be detected is The pull value is F t =50N.

[0079] In this embodiment, the five power wheels 1 are respectively provided with a driving system and provide a stable driving torque. Under the action of the traction system (not shown in the figure), the silk thread runs from the input end A to the output end B, so that the silk thread The tension value decreases along the direction of wire travel. Control the tension value F of the silk thread input end through the movable pulley (not shown in the figure) carrying the counterweight a It is 50N. There are 5 power wheels 1 in the present embodiment, through actual measurement data, each correlation coefficient Q imax >0.6, each correlation coefficient Q i Take 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com