Service life detection device and detection method for filter screen of oil pump

A detection device and filter net technology, which is applied in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve problems such as unstable oil pressure, decreased filtration efficiency, and increased after-sales costs, and achieves easy implementation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, invention will be further described.

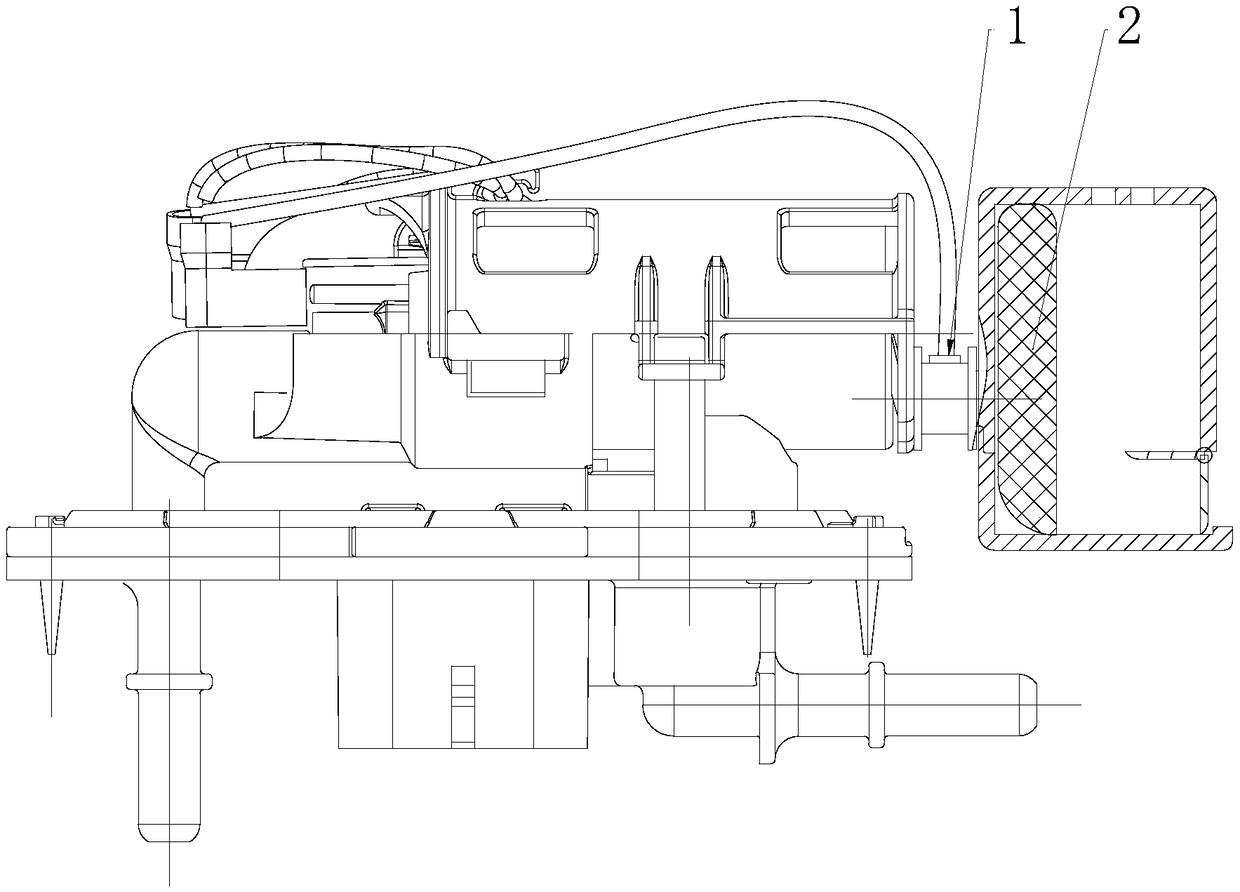

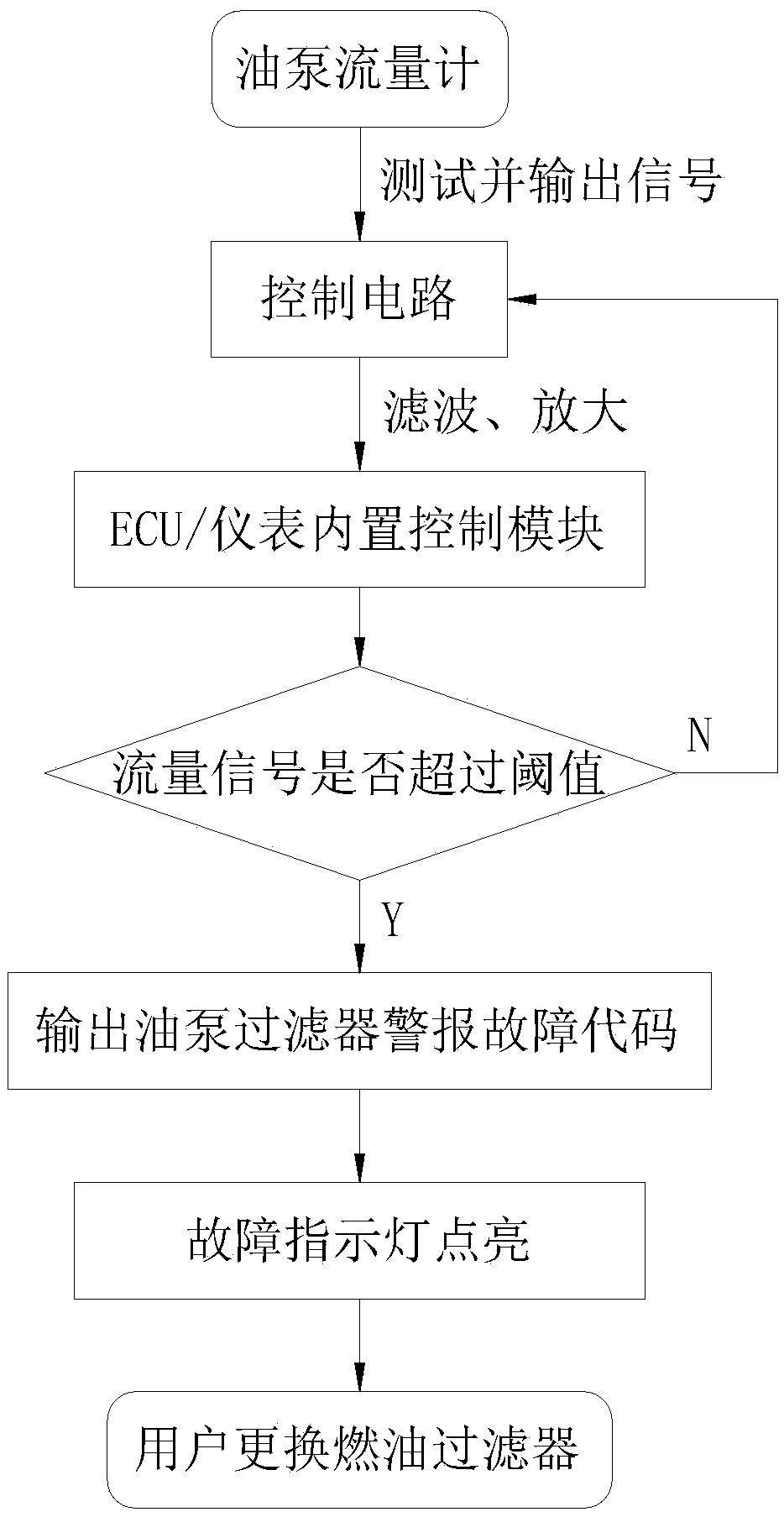

[0020] a kind of like figure 1 In the oil pump filter screen life detection device shown, the filter screen 1 is arranged at the oil inlet of the oil pump, and it is characterized in that the detection device includes an ECU control unit, a flow meter 2 and a warning unit arranged on the oil inlet road of the oil pump, and the flow rate Meter 2 detects the oil inlet flow signal of the oil pump, and its output end is connected to the flow signal input end of the ECU control unit, and the ECU control unit is connected to the warning unit. When the flow signal collected by the flow meter 2 is greater than the flow signal of the ECU When the flow threshold set in the control unit is reached, the ECU control unit controls the warning unit to issue a warning.

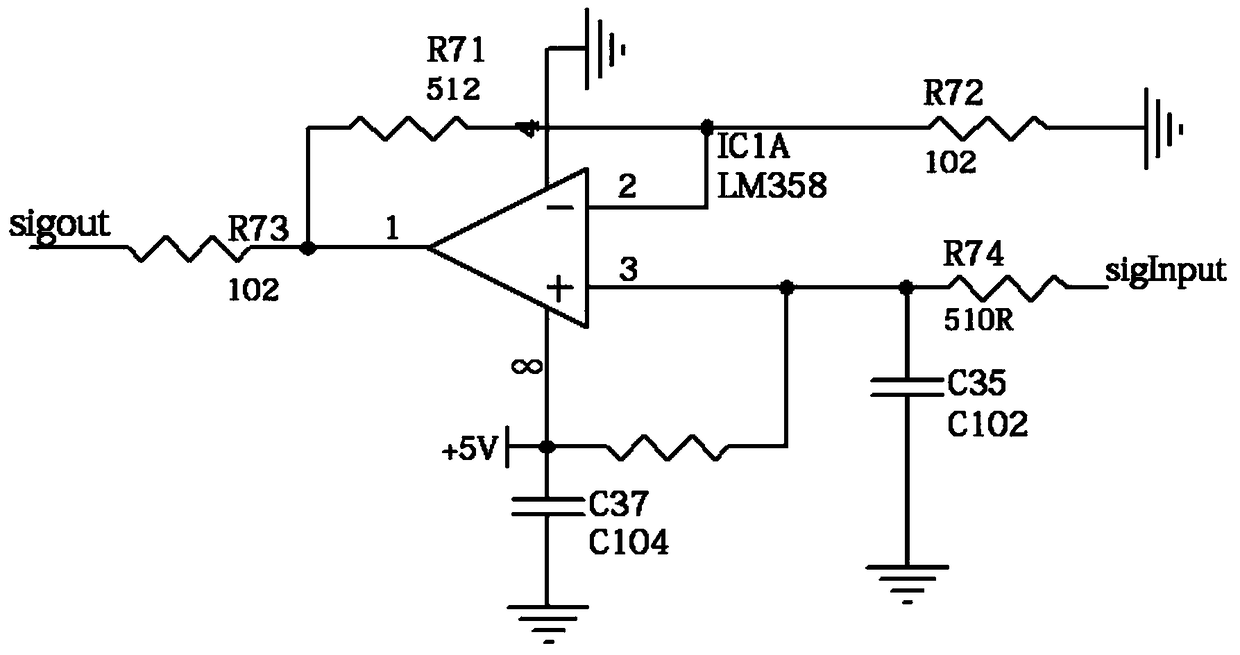

[0021] Further, the ECU control unit includes a comparator and a controller, the output terminal of the flow meter is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com