Method for detecting ingredients of high-frequency communication wire drawing liquid

A technology for component detection and drawing fluid, applied in the field of component detection of high-frequency communication wire drawing fluid, can solve problems such as deviation and affect the quality of wire drawing, and achieve the effect of compact technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with specific embodiments.

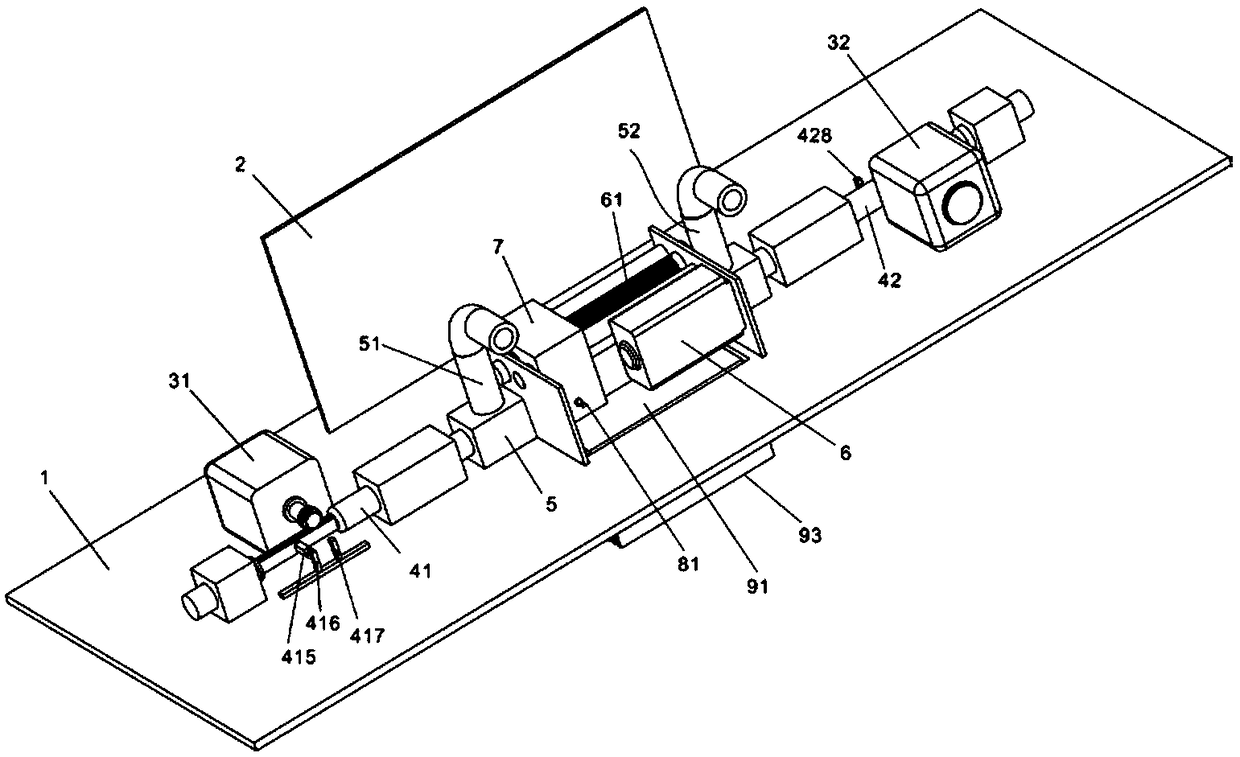

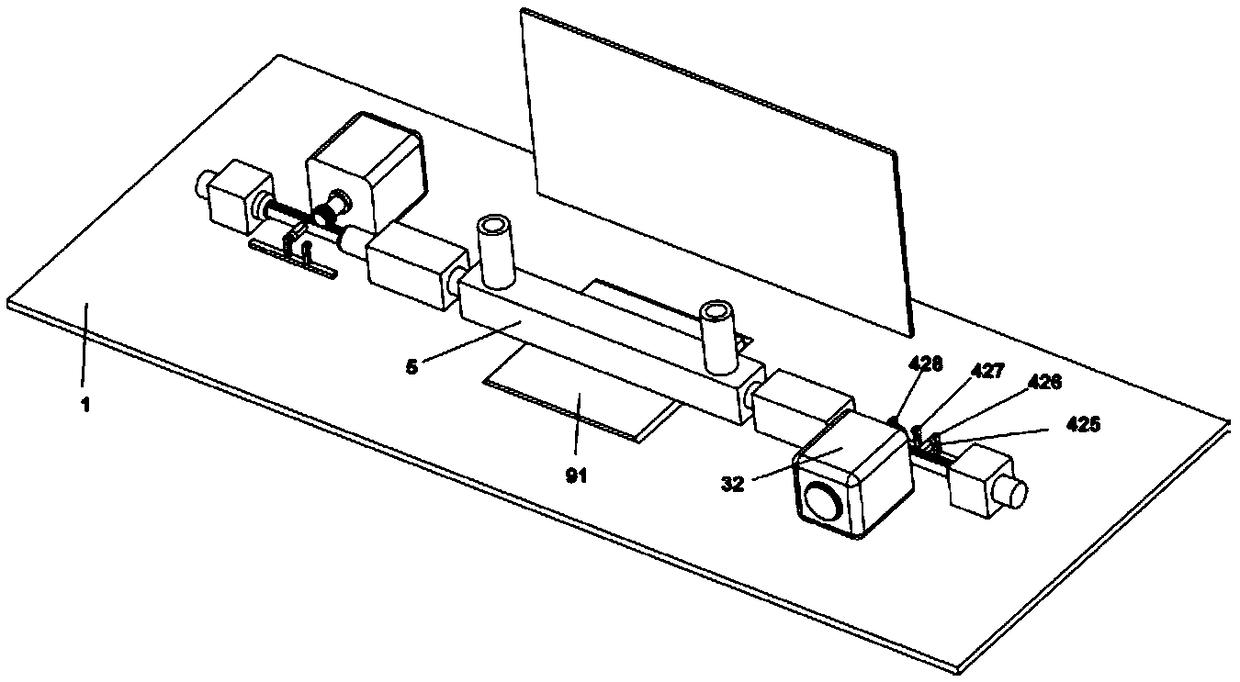

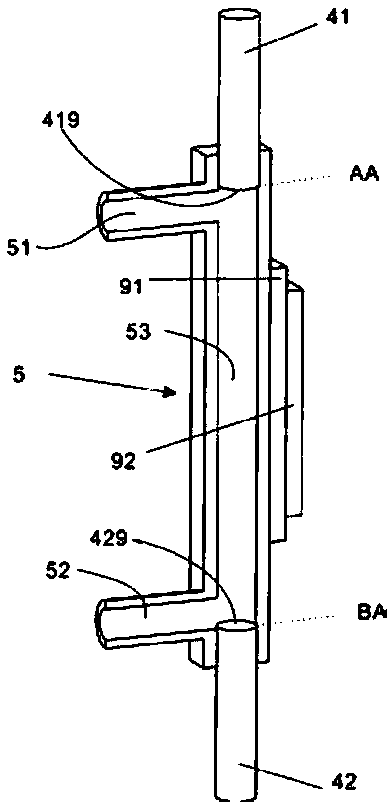

[0029] like Figure 1 to Figure 8 As shown, a method for detecting the composition of the high-frequency communication wire drawing liquid is implemented, comprising the following steps:

[0030] In the first step, at first the single-chip microcomputer 21 is set on the main circuit board 2 of the wire diameter detection device 1, and the inside of the single-chip microcomputer 21 is provided with a program memory 22, and the driver module 2111 including the upper piston and the lower piston are loaded therein. Piston driver module 2112, semiconductor cold pile refrigeration program module 2113, semiconductor cold pile heating program module 2114, cold pile fan driver module 2115, slider driver module 2116, upper piston first position detection program module 2117, upper piston Second position detection program module 2118, lower piston first position detection program module 2119...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com