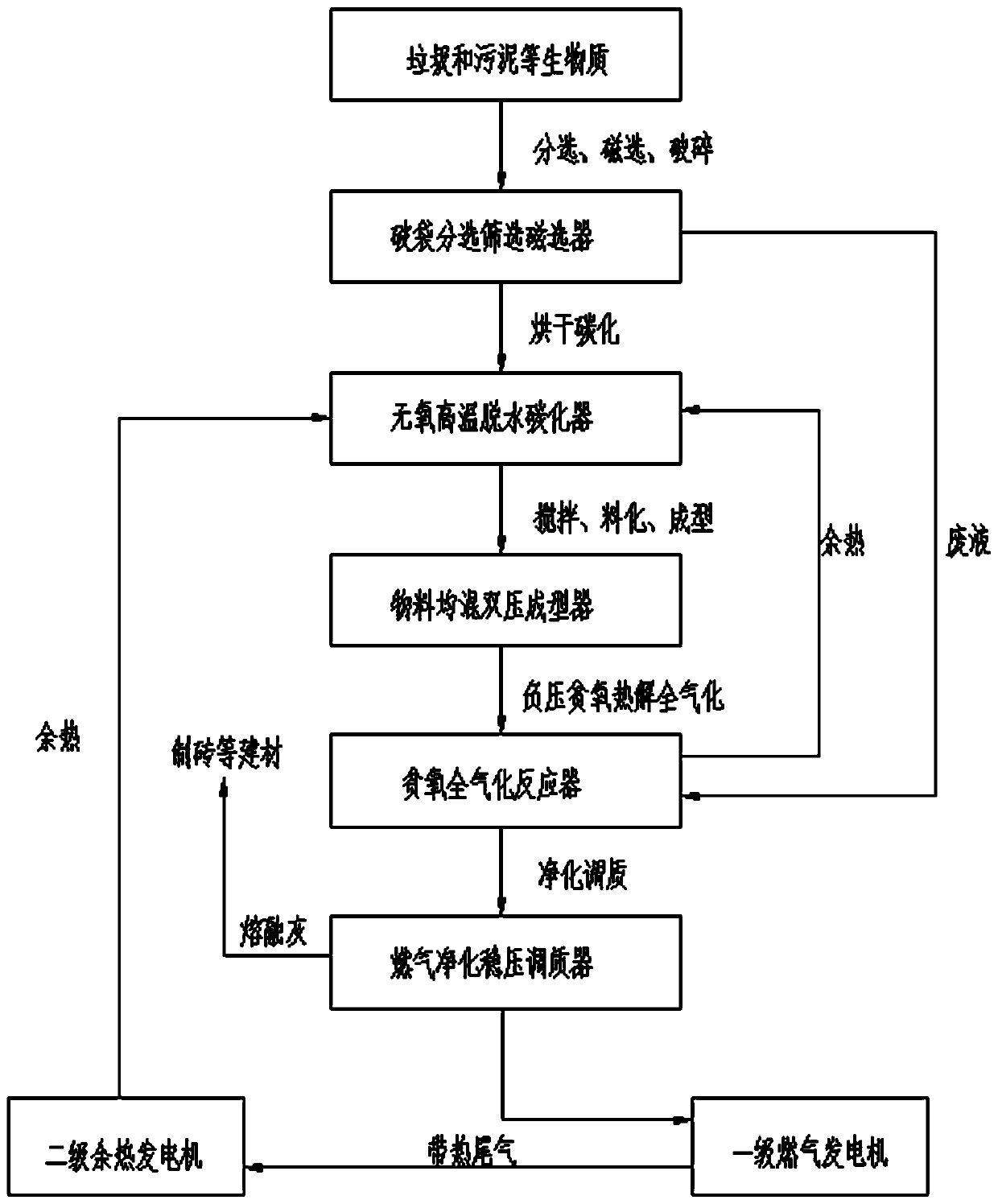

Whole-gasification power generation process with garbage and sludge

A sludge and garbage technology, which is applied in the field of garbage and sludge full gasification power generation process, achieves the effects of low operating costs, low operating costs and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail, should be understood that structure of the present invention is not limited to following embodiment:

[0028] Step 1: Sorting, magnetically separating, crushing, and pulverizing domestic waste through a bag-breaking sorting and screening magnetic separator to obtain raw materials for small powder and finished products and waste liquid;

[0029] Step 2: Dry and carbonize the small powder finished raw materials obtained in step (1) through an oxygen-free high-temperature dehydration carbonizer to obtain semi-finished fuel;

[0030] Step 3: The semi-finished fuel obtained in step (2) is stirred, materialized, and formed by a material homogeneous double-pressure molding machine to obtain a finished fuel;

[0031] Step 4: The finished fuel obtained in step (3) is subjected to negative pressure oxygen-deficient pyrolysis and full gasification at 1300°C through an oxygen-deficient full-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com