Methods and device for monitoring a beam guiding optical unit in a laser processing head during laser material processing

A laser processing head and optical device technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as damage to optical devices, and achieve the effect of compact structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

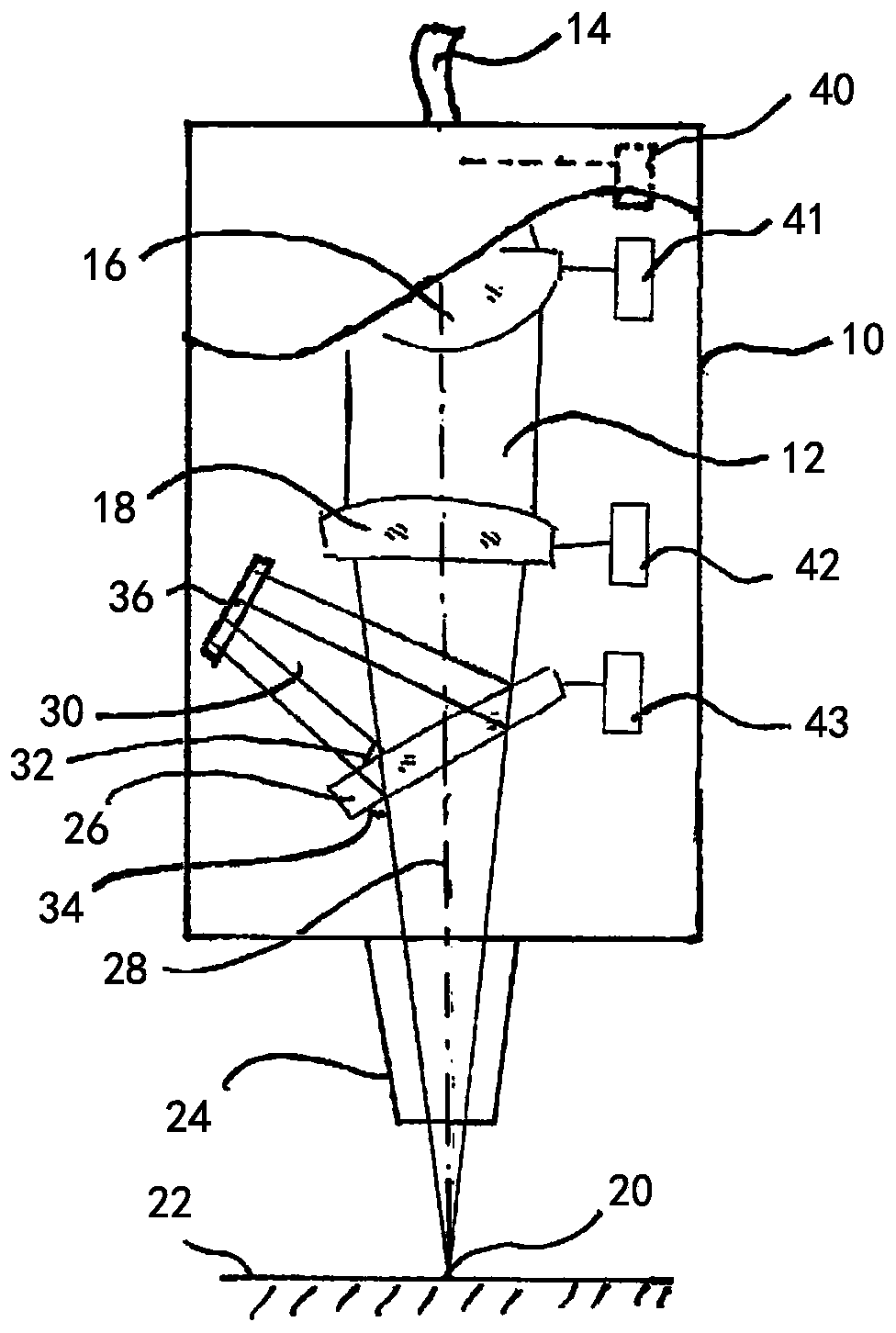

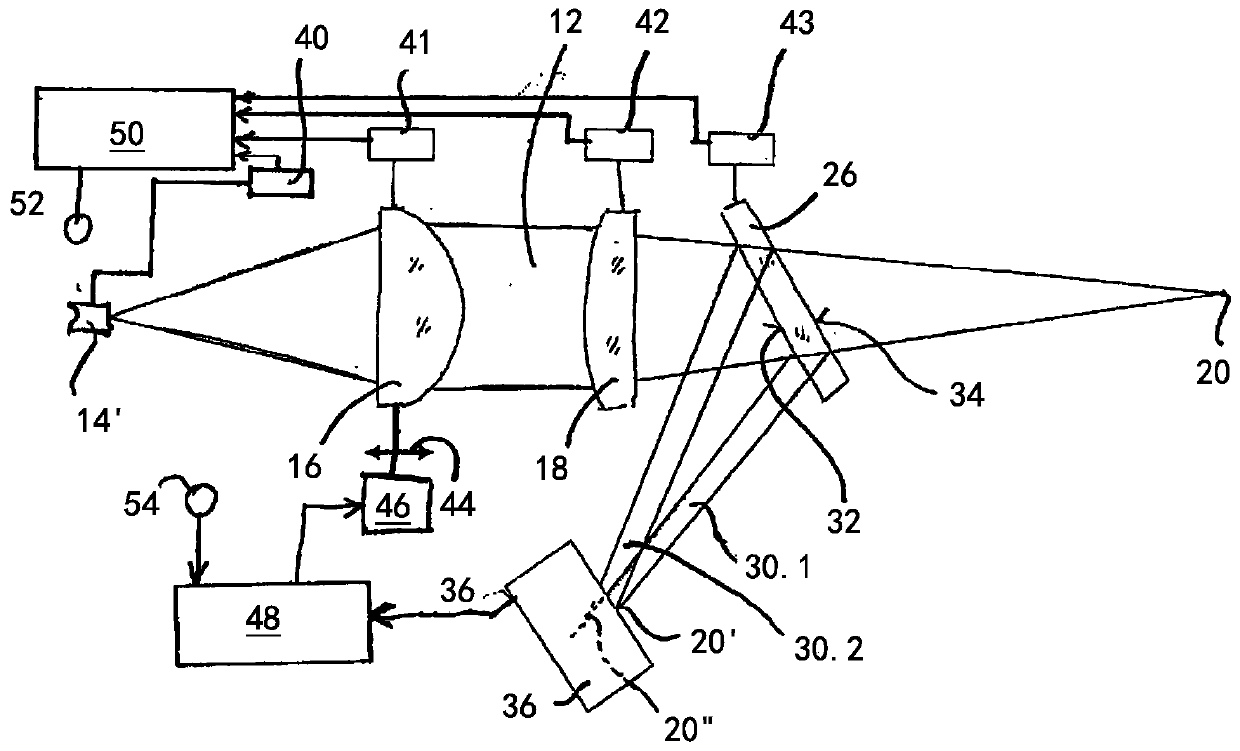

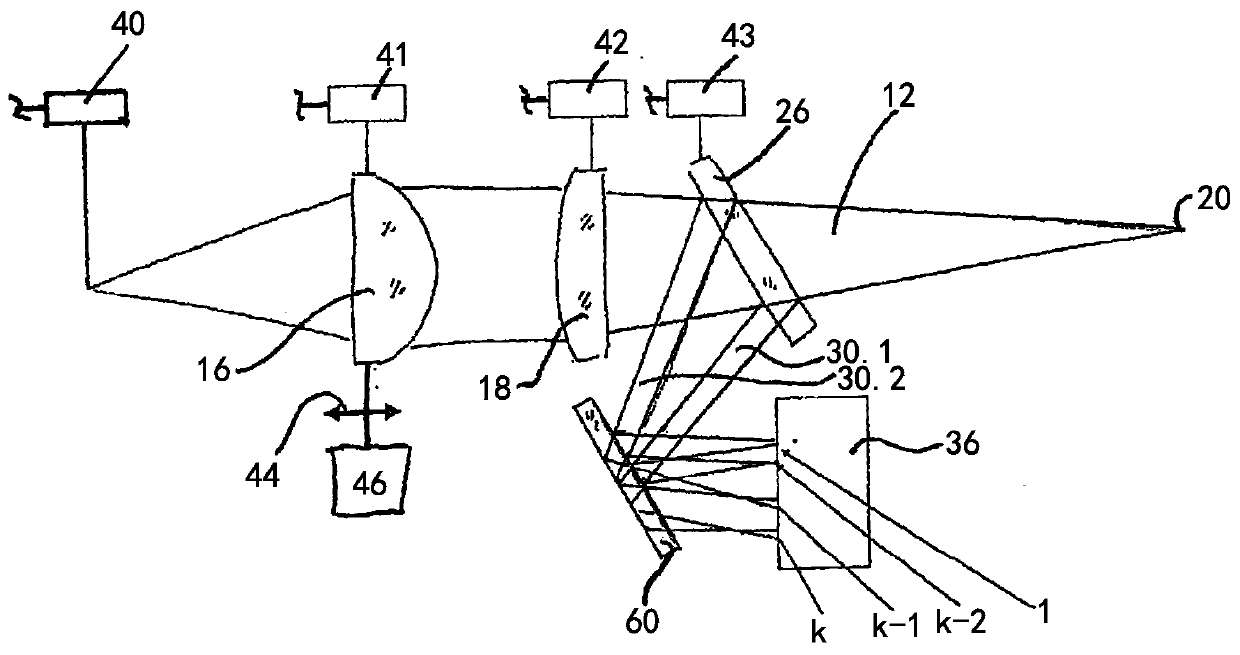

[0036] figure 1 The laser processing head 10 is schematically shown, through which the processing laser beam 12 is guided. This processing laser is supplied to the laser processing head 10 via the optical fiber 14, for example. The processing laser beam 12 emitted from the optical fiber 14 is collimated by the first optical device 16 and focused by the focusing optical device 18 into the laser focus 20 on the workpiece 22. A protective glass 26 is usually arranged between the focusing optics 18 and the beam nozzle 24 through which the converged processing laser beam 12 is focused on the workpiece 22, which should protect the interior of the laser processing head and especially The focusing optics 18 is protected from contamination, which may be caused by spatter or dense smoke, for example.

[0037] The first optics 16 and the focusing optics 18 are shown as a single lens, but may also be known as a lens group. The first optics 16 can in particular consist of a movable lens of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com