High speed visual detection and recognition equipment

A technology for visual inspection and identification equipment, applied in the field of visual inspection and identification, can solve the problems of high cost, low circuit board efficiency, low identification accuracy, etc., and achieve the effect of low cost, simple structure and simplified equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

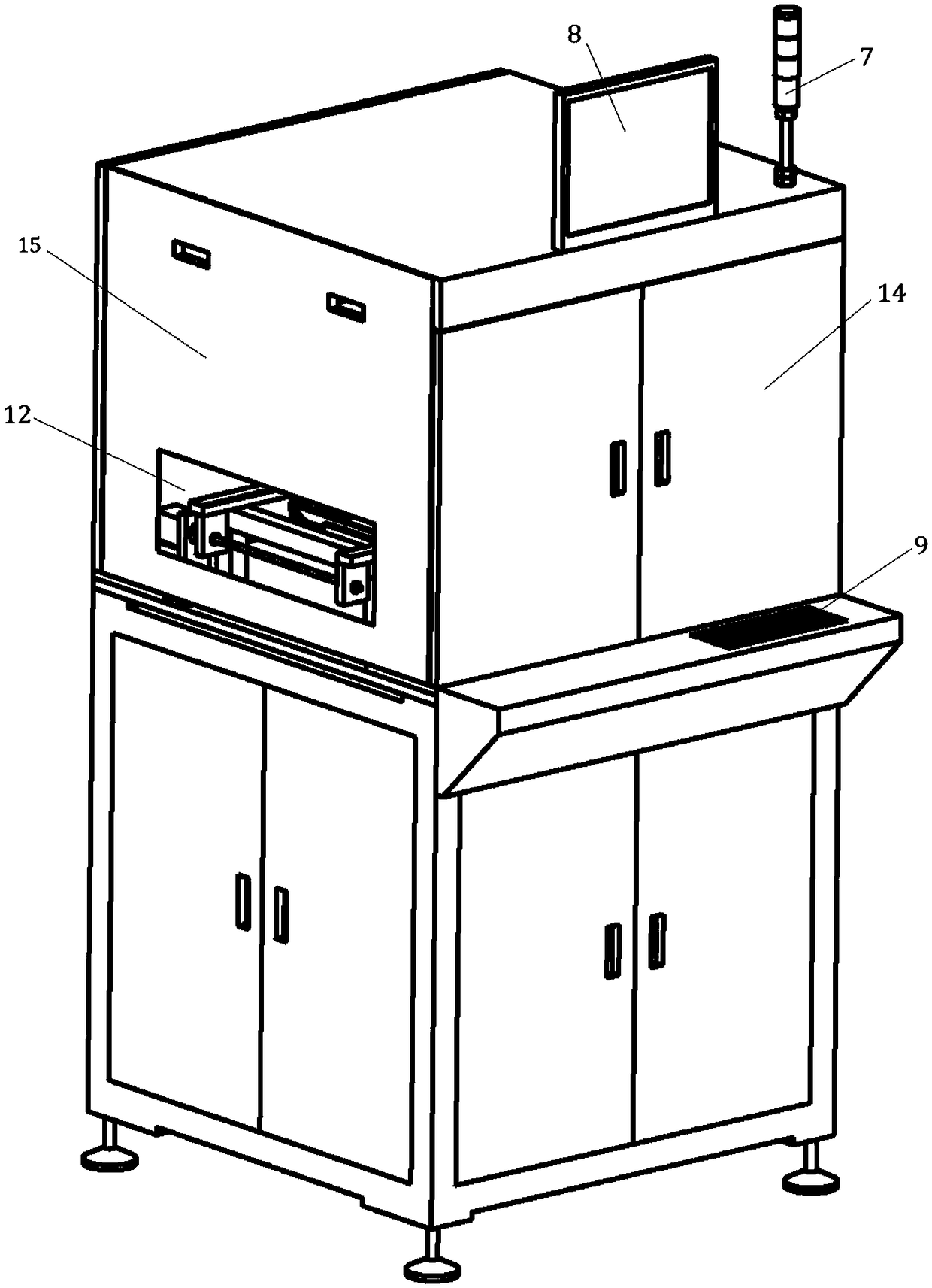

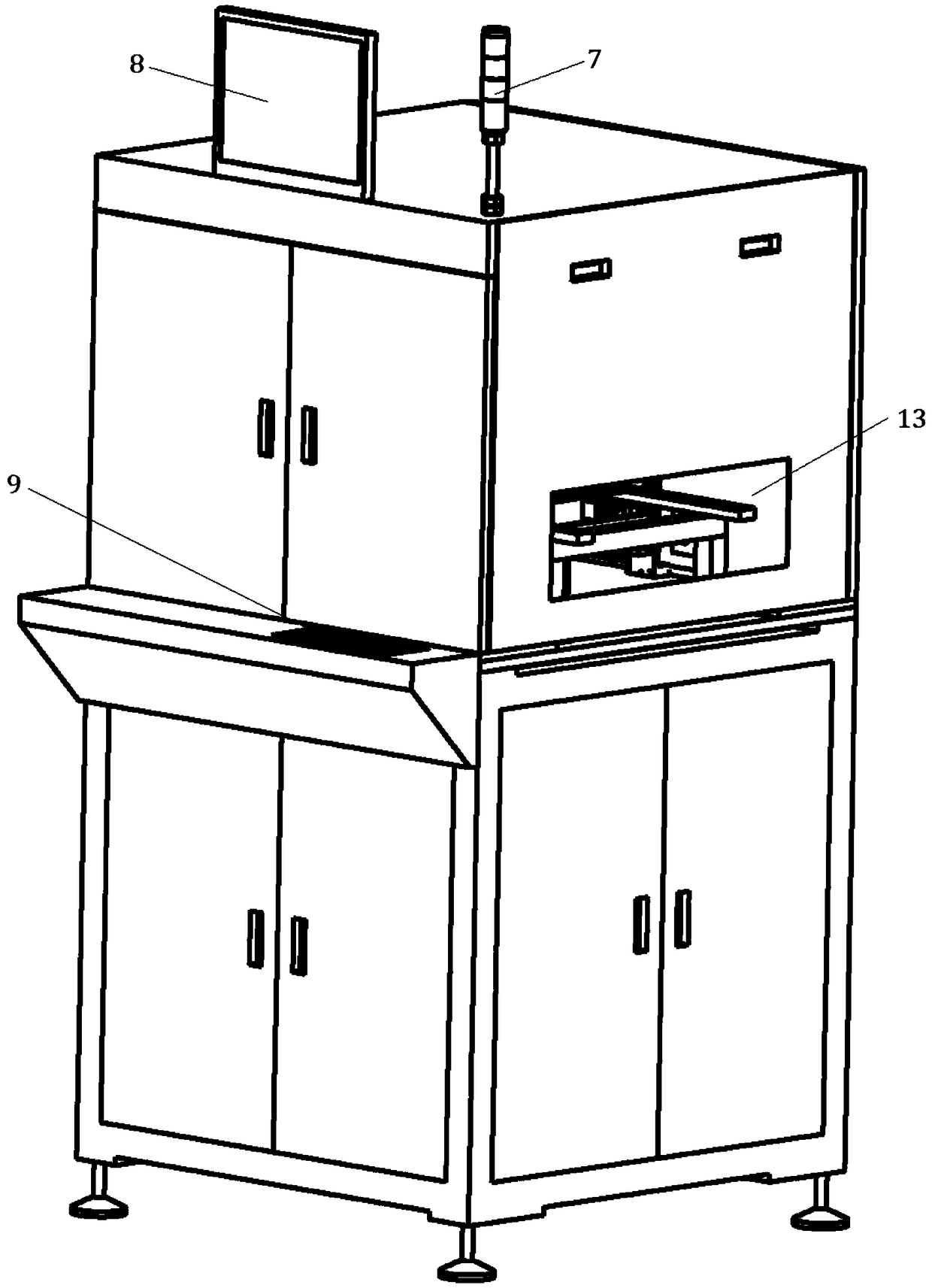

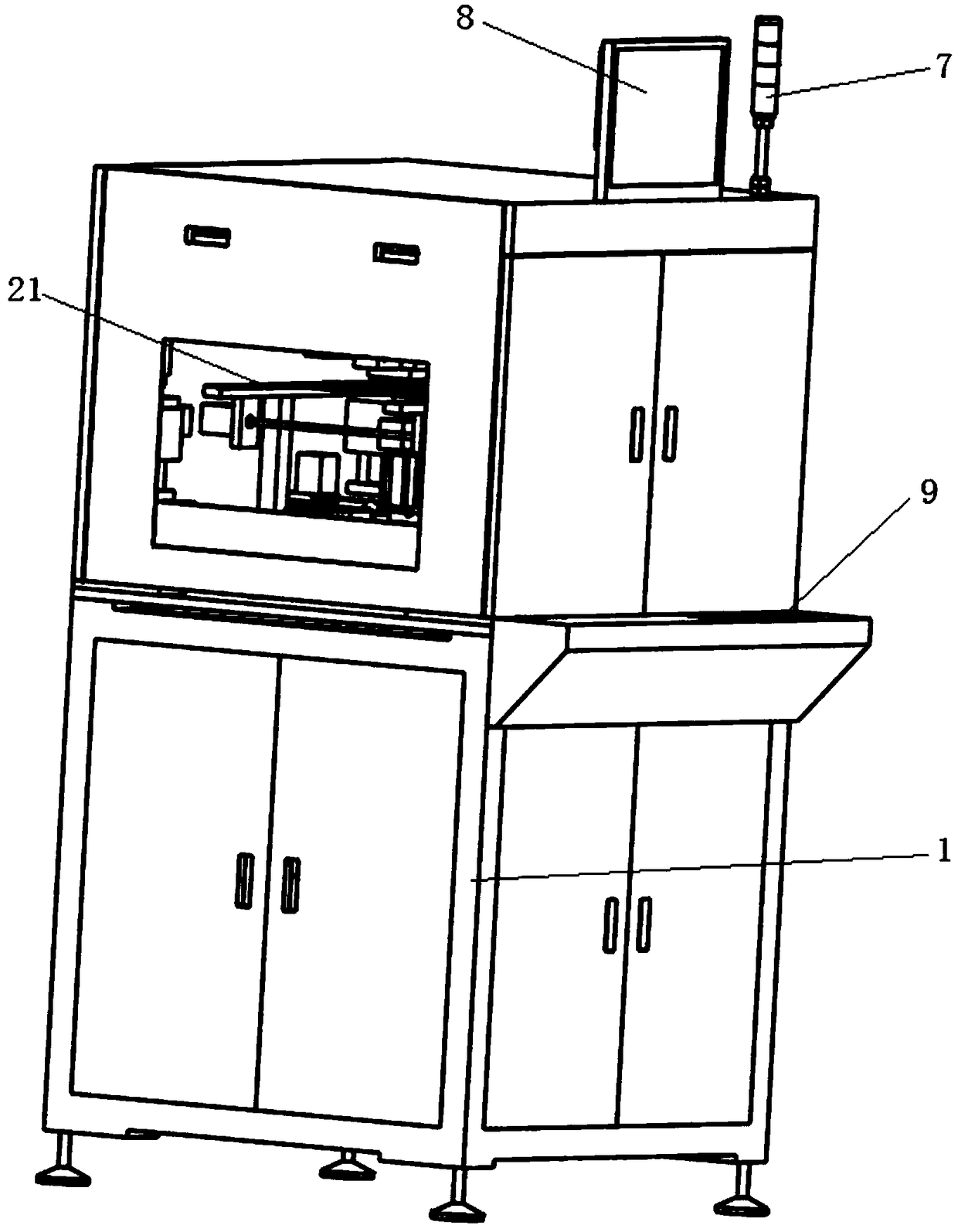

[0041] refer to Figure 1-4 As shown, an embodiment of the high-speed visual inspection and identification device of the present invention is provided, including a main body support 1, a carrying platform 2 arranged in the middle of the main body support 1 for placing and delivering finished circuit boards to be detected and identified, and arranged on the top of the main body support 1 And the first moving mechanism 31 movable along the Y-axis direction, the first photographing device 41 arranged at the lower end of the first moving mechanism 31 for taking images of finished circuit boards, and the first moving mechanism 31 arranged in the main body support 1 and the first photographing device 41 are connected to the control device 6 for controlling.

[0042] refer to Figure 4-7 As shown, it also includes a first Z-axis motion mechanism 314 arranged at the lower end of the first motion mechanism 31 and movable in the Z-axis direction. The first angle adjustment device 315 ...

no. 2 example

[0060] Compared with the first embodiment, this embodiment also includes a fourth movement mechanism 34 arranged at the bottom of the main body support 1 and movable along the Y-axis direction, and a fourth movement mechanism 34 arranged at the upper end of the fourth movement mechanism 34 with the lens facing the finished line The fourth photographing device 44 for photographing the reverse image of the finished circuit board on the reverse side of the board. Its specific structure is the same as that of the first motion mechanism 31, and it can be moved in the Y-axis direction. The fourth motion mechanism 34 is provided with a fourth photographing device 44, so that the image of the reverse side of the finished circuit board can be photographed. In this embodiment It is set that the fourth photographing device 44 is perpendicular to the bottom surface of the finished circuit board to photograph images.

[0061] More specifically, it also includes a second Z-axis motion mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com