Automatic feeding device for pressure gauge assembler

A technology of automatic feeding and pressure gauge, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

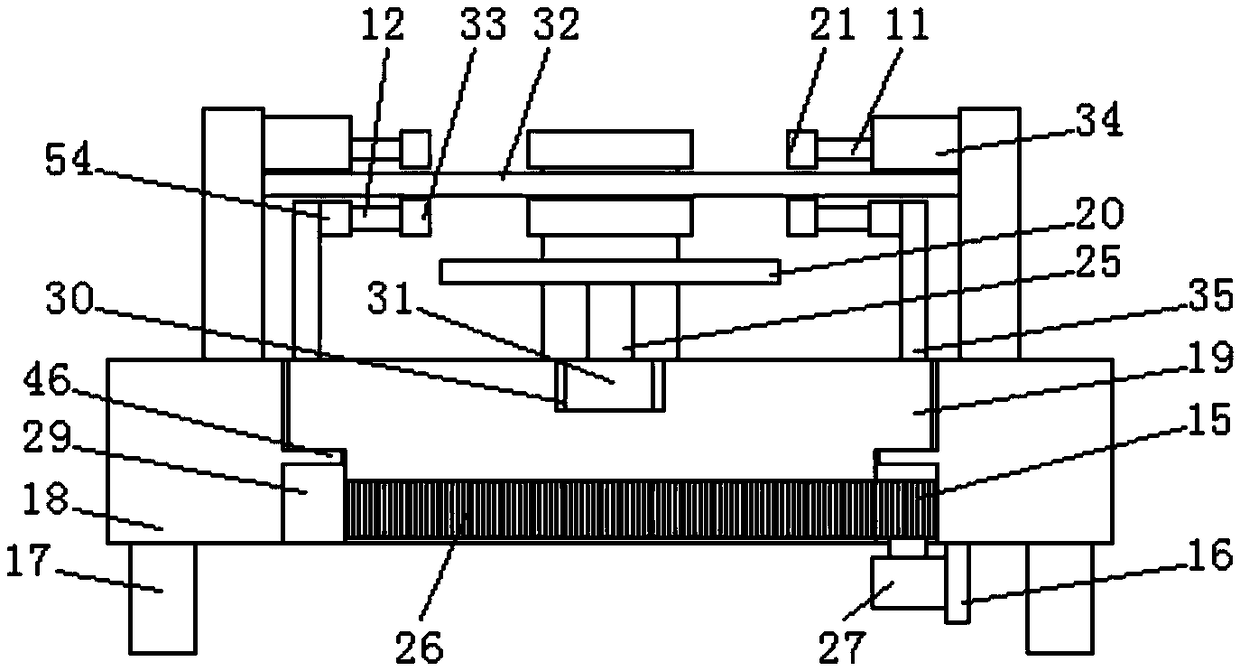

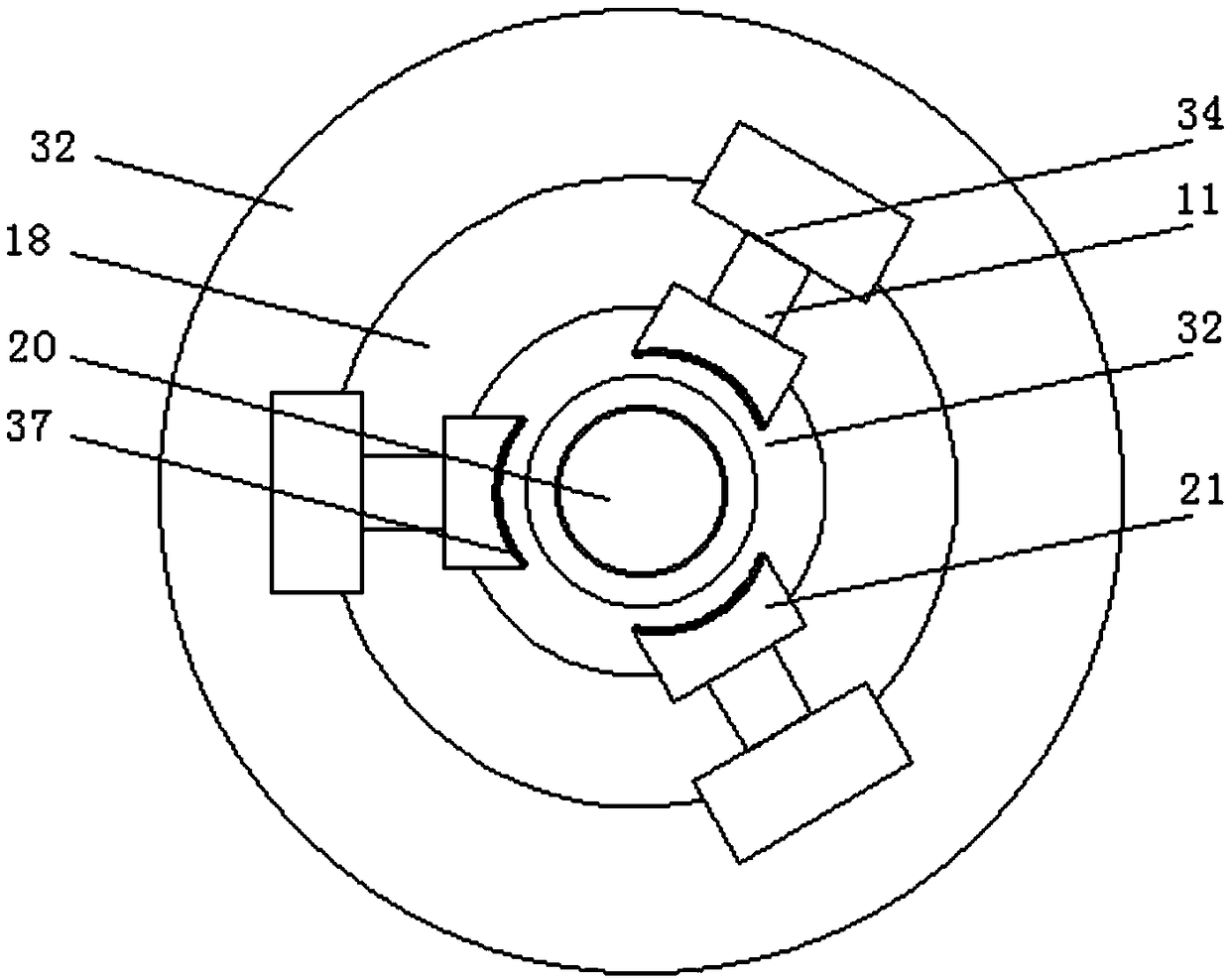

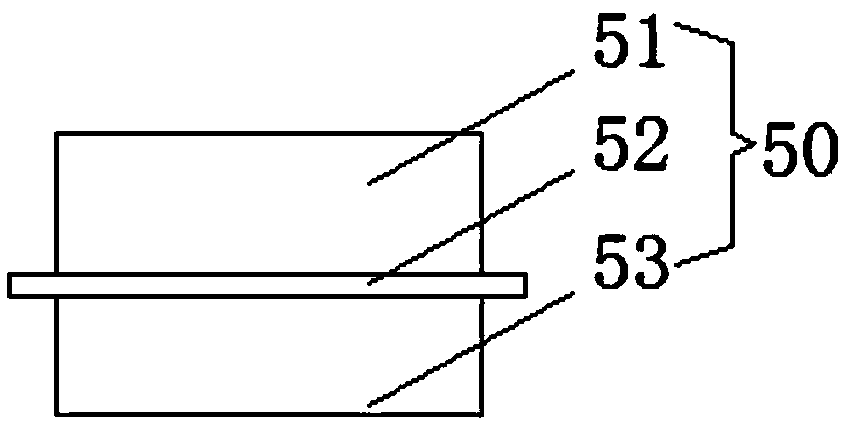

[0039] Embodiment 1, an automatic discharge device for a pressure gauge assembly machine, comprising a first conveyor belt 23, a fixed base 18, a pressure gauge 50 and a rotating base 19, the pressure gauge 50 is composed of a bottom cover 53, an upper cover 51 and a fixed The outer edge 52 is composed of the outer edge 52. The fixed outer edge 52 is arranged at the joint between the bottom cover 53 and the upper cover 51. The middle part of the fixed base 18 is provided with a rotation hole 29, and the inner wall of the middle part of the rotation hole 29 is provided with a fixing device for fixed connection. Ring 46, the fixed ring 46 is provided with a matching rotating base 19, the fixed base 18 is provided with a number of first fixed mounts 13 symmetrically distributed in the center, and the upper ends of the first fixed mounts 13 are provided with The first fixed bracket 13 is vertically fixedly connected to the first electro-hydraulic regulator 34, and the first electro...

Embodiment 2

[0048] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0049] Further, the height of the fixing rod 24 on the side close to the conveying table 7 is higher than the height of the fixing rod 24 on the other side of the first conveying belt 23 . The second conveyor belt is set at a slant, so that the positioning frame can continuously rise when pushing the pressure gauge, so that the positioning frame can be separated from the pressure gauge effectively when the pressure gauge is pushed to the upper end of the conveying pipe, thus successfully for the next cycle.

Embodiment 3

[0051] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0052] Preferably, the outer side of the upper end of the tray 20 is provided with a positioning groove 56 matching the size of the bottom cover 53 .

[0053] Further, a vertical connection delivery pipe 8 is provided between the delivery hole 55 and the support ring 32, the diameter of the delivery pipe 8 is larger than the inner diameter of the support ring 32, and the diameter of the delivery pipe 8 is smaller than the outer diameter of the support ring 32 , the two sides of one end of the positioning groove 56 are provided with symmetrically distributed adjusting grooves 43, the adjusting grooves 43 are provided with a connecting shaft 44 for movable connection, and the connecting shaft 44 is provided with a fixedly connected discharge rod 38, The inner wall of the support ring 32 is provided with a card slot 13 matching the discharge rod 38, the card slot 13 is arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com