Adjustable double-station tin plating device for copper-clad steel wire

A technology of copper-clad steel wire and tin-plating device, which is applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of lack of tin-plating device and low production efficiency, achieve convenient tin-plating, improve Utilization, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

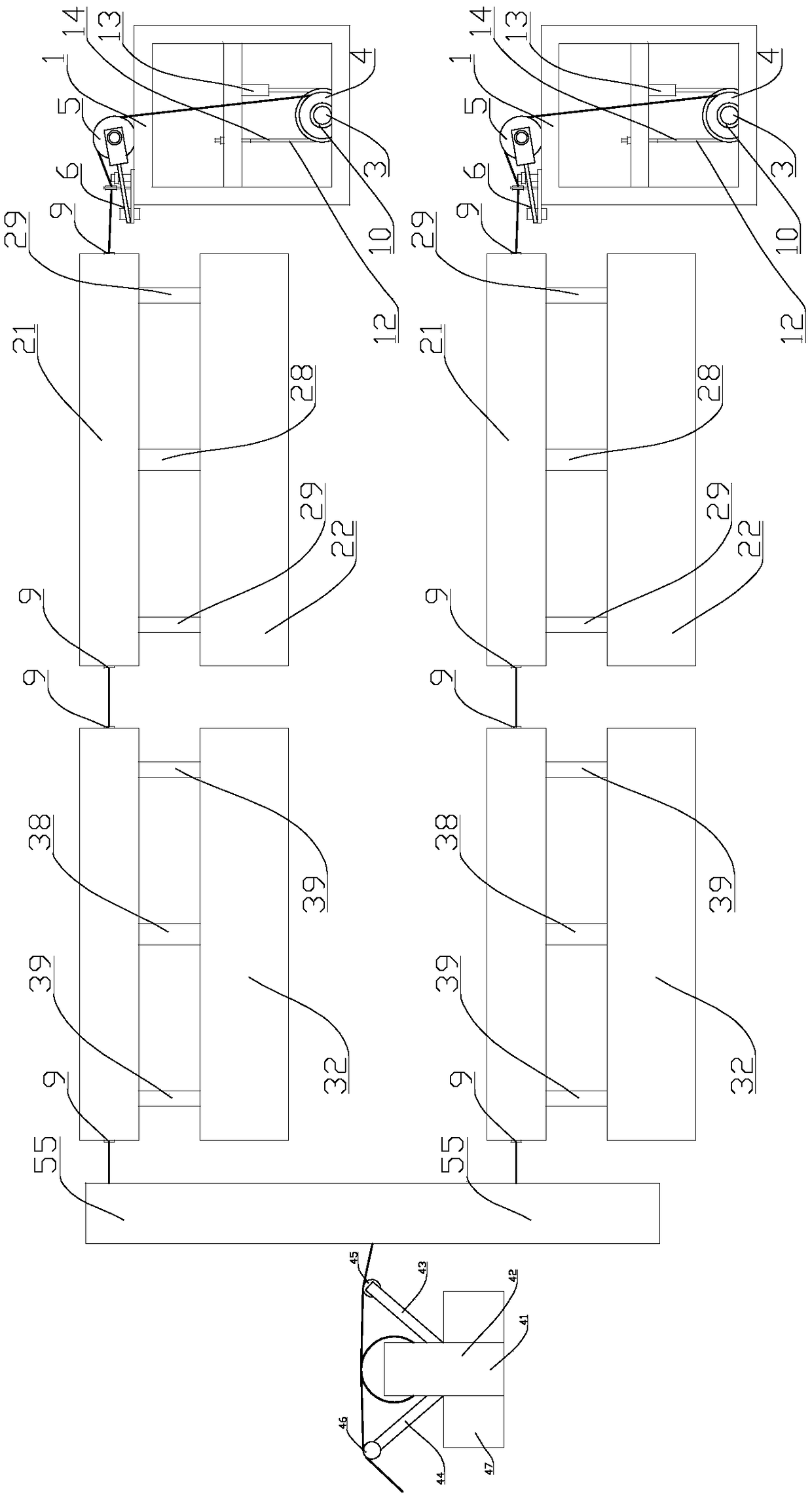

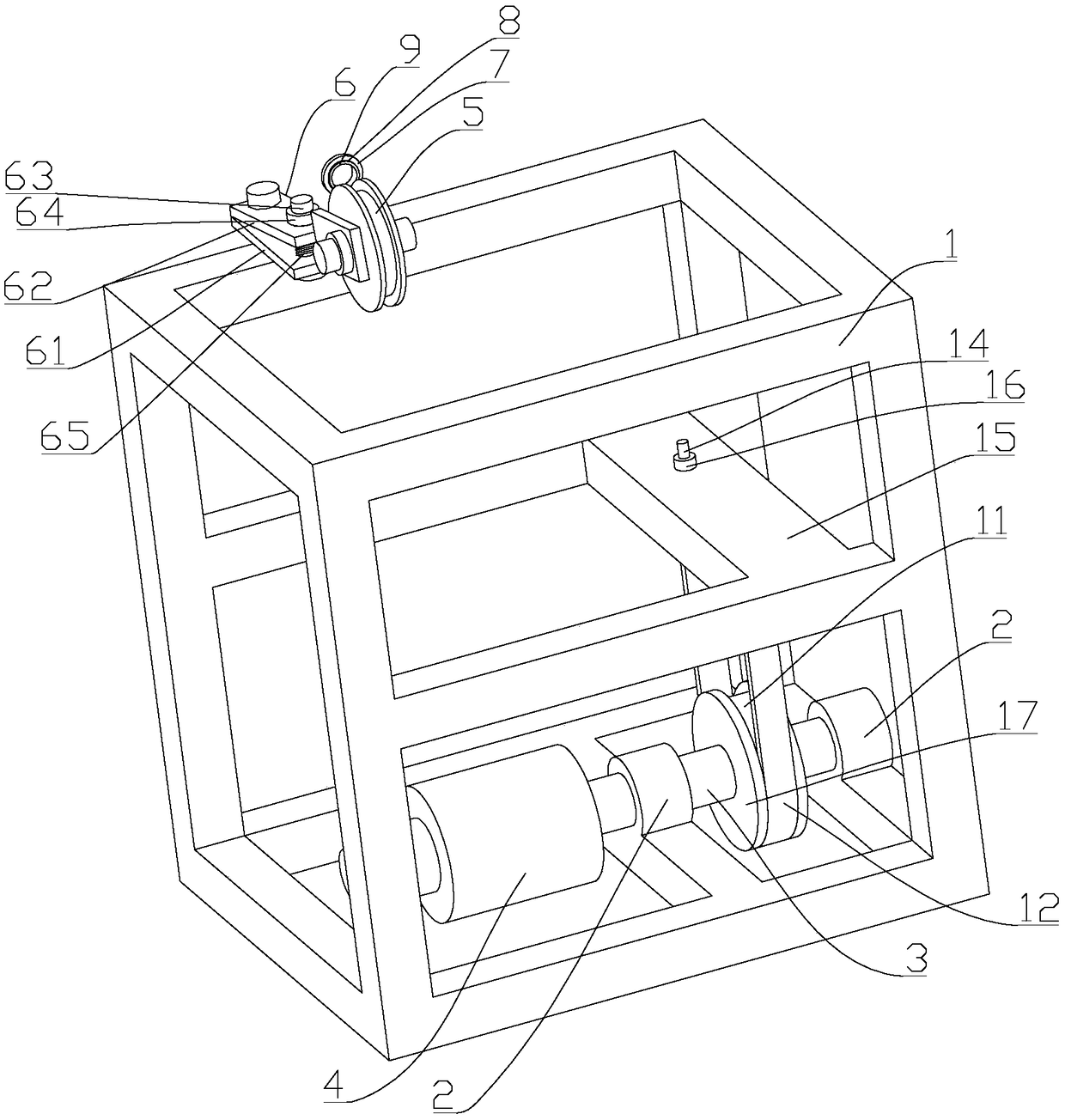

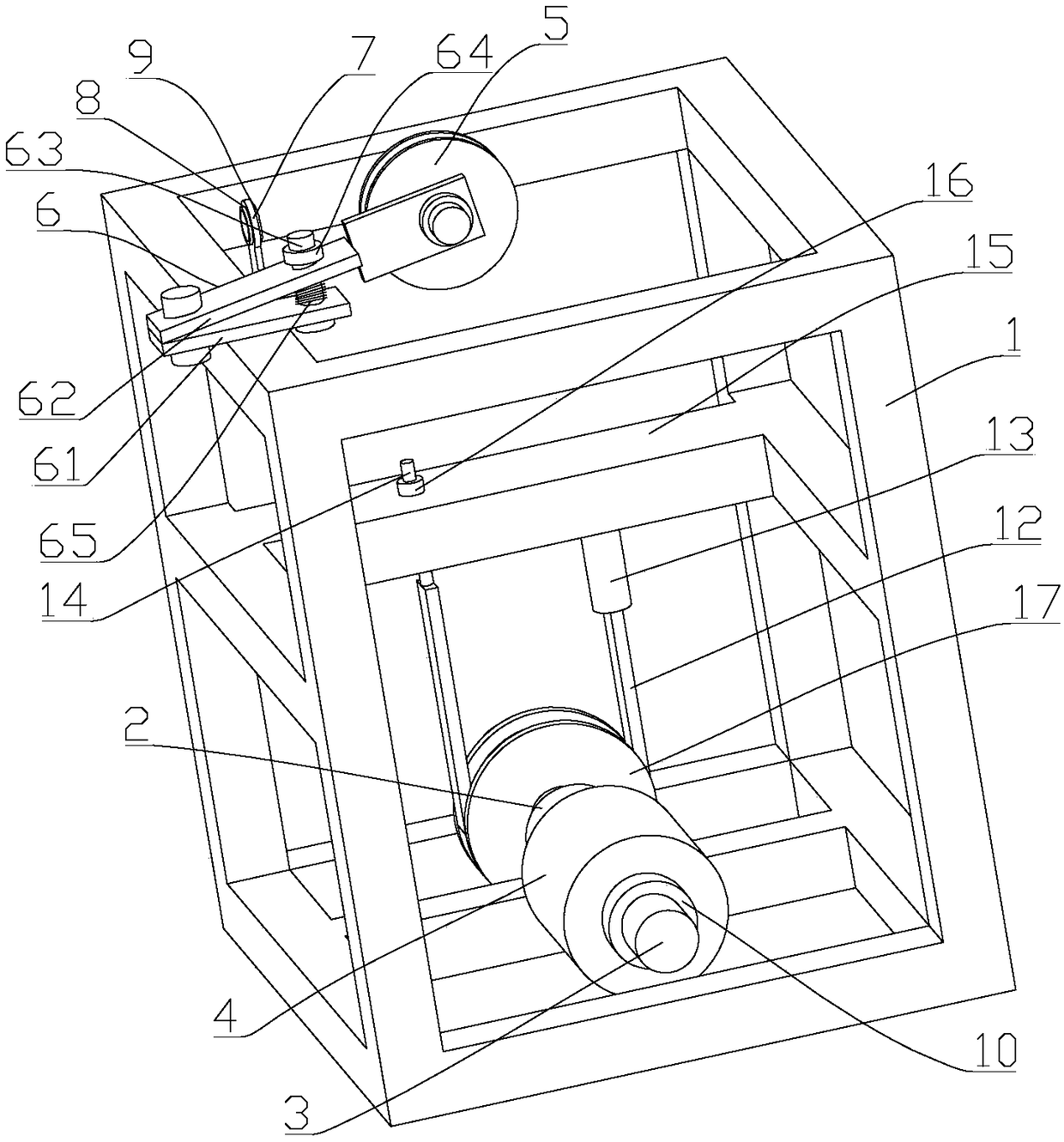

[0031] Such as figure 1 , 2 , a kind of adjustable copper-clad steel wire double-station tinning device shown in 3, 4, 5, 6, comprises lead frame, cleaning device, soldering aid device, tin furnace 55 and outlet cooling device connected successively before and after, There are two lead frames, arranged side by side at the front of the cleaning device; there are two cleaning devices, arranged side by side at the rear of the lead frame; there are two fluxing devices, arranged side by side at the cleaning the rear of the device;

[0032] The lead frame includes a bracket 1, a pair of coaxial bearing housings 2 are fixed on the bottom of the bracket 1, and a rotating shaft 3 is provided through bearings in the two bearing housings 2, and the rotating shaft 3 is mounted on the two bearing housings. The outer side of 2 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com