Rail cooling system and cooling method for electromagnetic railgun

A technology for electromagnetic rail guns and cooling systems, applied in electromagnetic launchers, weapons without explosives, offensive equipment, etc., can solve the problems of rail gun cooling methods such as complex process, difficult operation and control, and track surface damage, and achieve good electrical conductivity Effects, easy operation and control, effects with less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

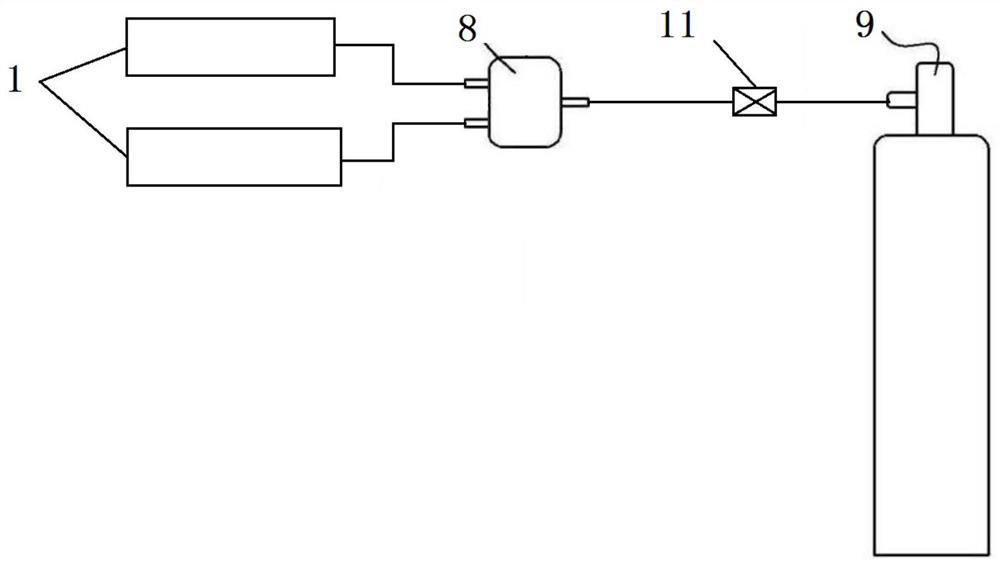

[0042] A specific embodiment of the present invention discloses a track cooling system of an electromagnetic rail gun, comprising a cooling passage arranged in the guide rail (rail) 1 of the electromagnetic rail gun, a liquid storage tank 9 for storing coolant, and a cryogenic liquid pump 8; the cooling channel 4 is arranged along the length direction of the guide rail 1; the cryogenic liquid pump 8 transports the coolant in the liquid storage tank 9 to the cooling channel 4, and the rail cooling system of this embodiment also includes a valve for controlling the flow rate of the coolant body 11, and the valve body 11 is arranged between the cryogenic liquid pump 8 and the liquid storage tank 9.

[0043] The working process of the electromagnetic railgun is:

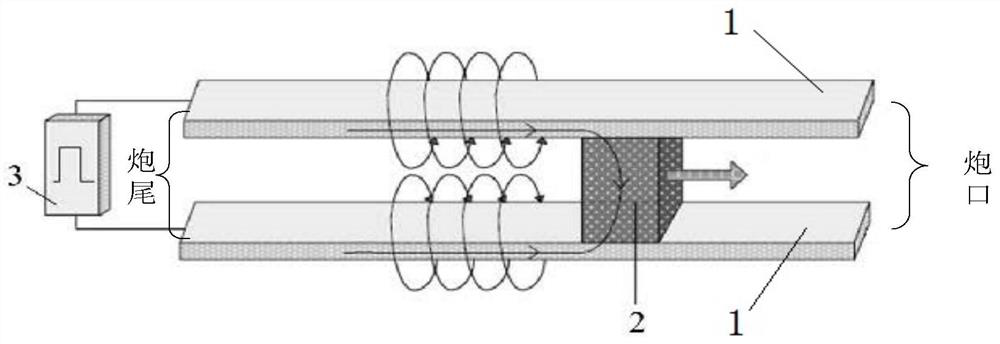

[0044] The guide rail 1 includes the first guide rail and the second guide rail, the circuit is turned on, the pulse power supply 3 provides current, the current passes through the first rail, the armature 2 and the seco...

Embodiment 2

[0057] Considering the movement characteristics of the armature, the temperature at the muzzle end is higher than that at the tail end of the gun. Therefore, the cooling of the track is mainly concentrated in the middle and rear sections. In actual use, the coolant is generally passed through the tail end of the gun. The reason is that: if The coolant is introduced from the muzzle end, then the nitrogen gas after liquid nitrogen gasification will be discharged from the tail end of the gun, and other equipment and cables are arranged at the tail end of the gun. Higher temperature nitrogen will reduce the service life of other equipment. And it will accelerate the aging of the cable.

[0058] In order to reduce the temperature at the muzzle end quickly, in this embodiment, the front section of the cooling channel is arranged along the length direction of the guide rail, and the rear section of the cooling channel is set in the direction of the contact surface between the guide ra...

Embodiment 3

[0065] Considering both source and cost, the coolant in the embodiment of the present invention may also be water. Considering that ordinary tap water contains impurities, and the impurities have a conductive function and will affect the distribution of current density, therefore, the coolant in this embodiment is selected as deionized water.

[0066] Because only a small part of the deionized water is vaporized after flowing through the cooling channel, most of the deionized water still exists in the form of liquid water, so the track cooling system of this embodiment also includes a return pipe, and the deionized water coming out of the cooling channel passes through The return line is drained.

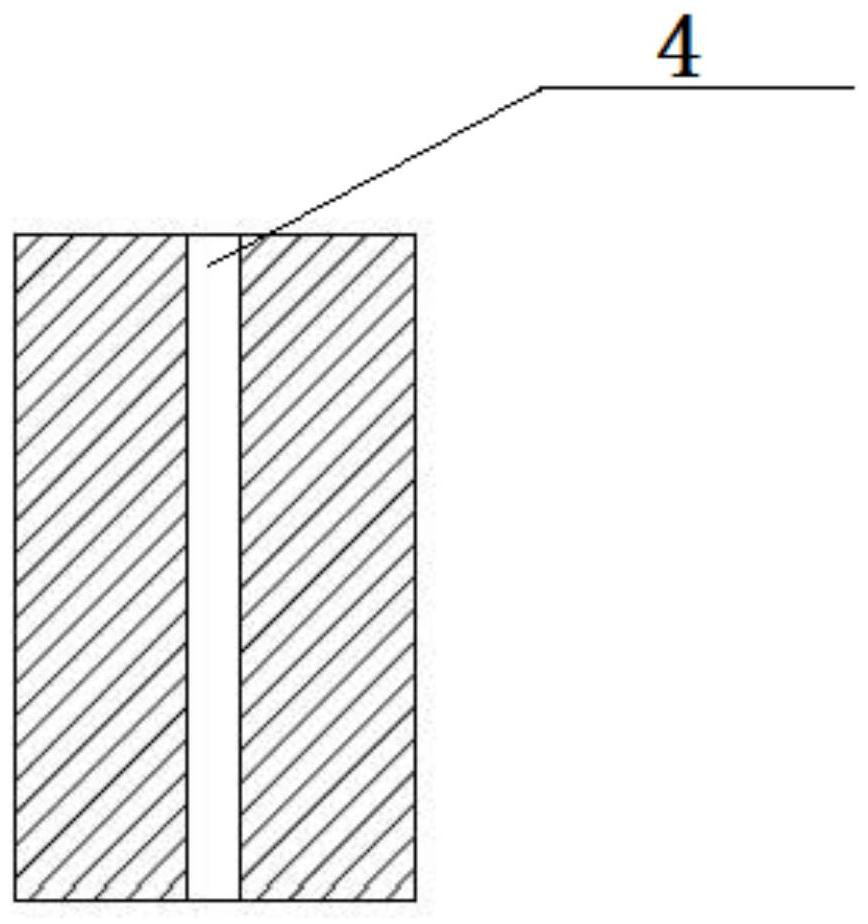

[0067] In order to fully exchange heat and cold between the deionized water and the guide rail, the cooling channel in this embodiment is set in a U-shape 7 . Considering that it is cumbersome to open a U-shaped cooling pipe in the track 1, it is difficult to directly open a hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com