In-situ test device and method for testing shear strength and long-term creep deformation of rock sample

A technology of shear strength and creep deformation, applied in the direction of applying stable shear force to test material strength, mechanical solid deformation measurement, etc., can solve the problems affecting the accuracy of test results, uneven force on the shear surface, shear Problems such as poor process stability, to achieve the effect of more reliable test results, low cost, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

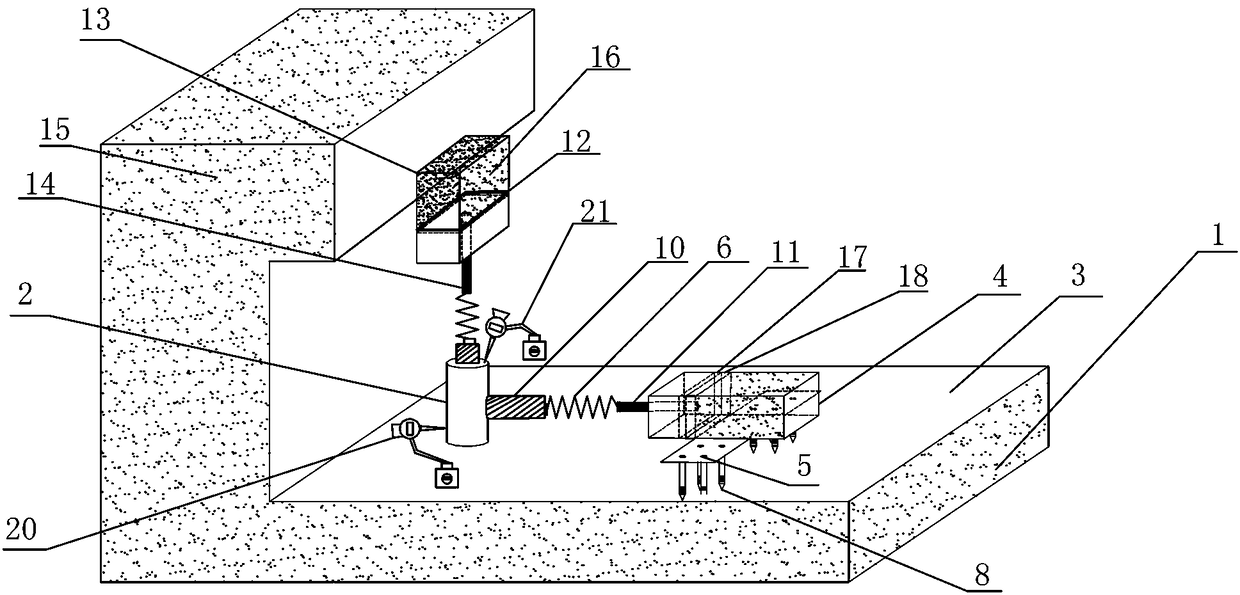

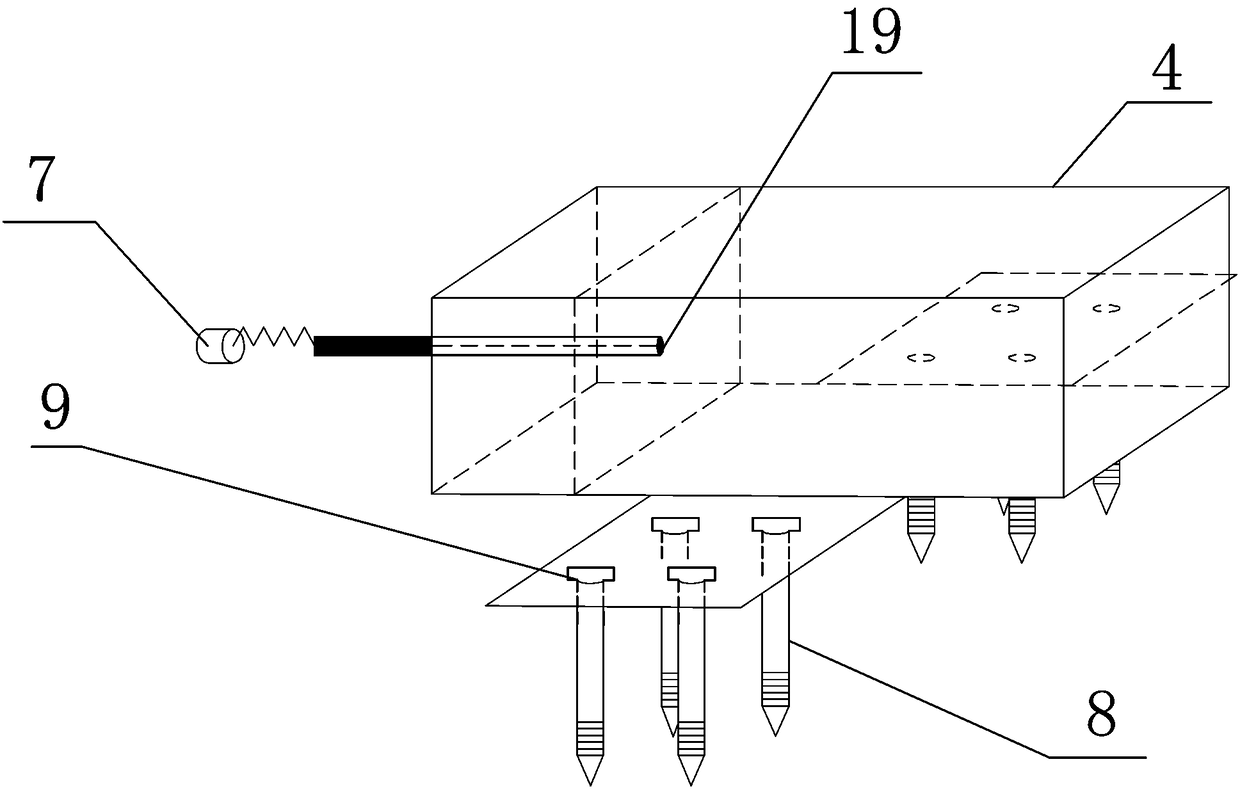

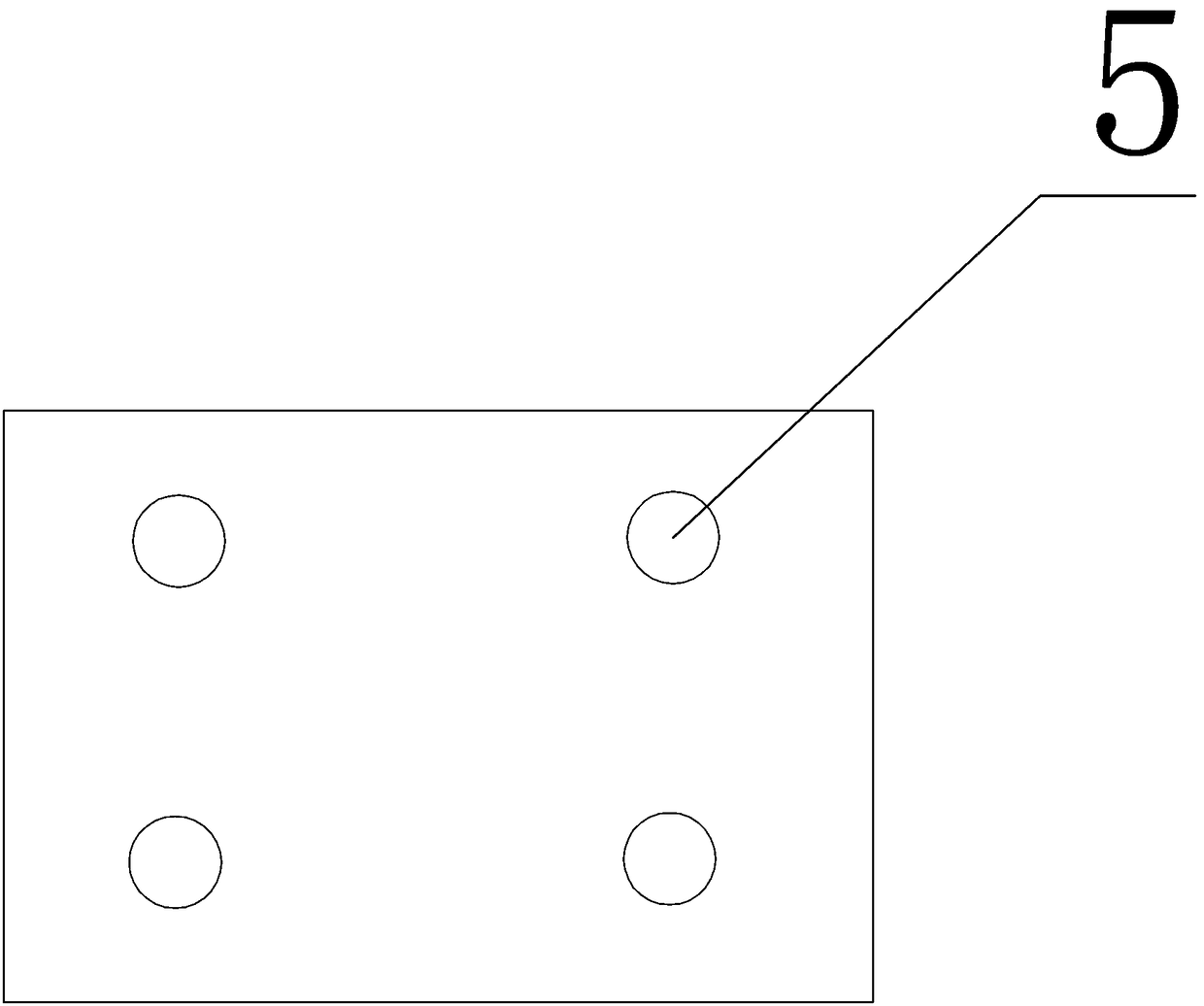

Embodiment 1

[0052] An in-situ test device for testing the shear strength and long-term creep deformation of a rock sample, which includes a surrounding rock 1 and a rock sample 2 to be sheared, and a horizontal shear box 4 is fixed on a flat surrounding rock surface through a threaded ground anchor 8 3. In the horizontal shear box 4 and the vertical load loading box 16, pour the expansion cement slurry 13 with a large amount of expansion agent, and the expansion force generated can pass through the force transmission plate 12 of the dumbbell-shaped shear bar 7, the dowel bar 11, and the Adjust the butterfly spring 6 and the loading probe 10 to apply vertical load and horizontal shear load on the rock sample 2 to be sheared, and monitor the data in the test process through the pressure sensor 19 and the shear displacement percentage meter 20 to draw the shear stress The relationship curve between the normal stress and the shear strength parameters of the rock mass on the specific failure su...

Embodiment example 2

[0074] Any in-situ testing device and method for testing rock sample shear strength and long-term creep deformation is characterized in that it includes the following steps:

[0075] Step1: Clean up the surrounding rock: select the surrounding rock surface with better lithology, and clean up the weeds and gravel on the surrounding rock to be cut;

[0076] Step2: Cutting rock samples and test platform: Use cutting equipment to cut and grind an over-excavation test platform, which is in the shape of a concave regular hollow cube, including sheared rock samples, flat surrounding rock surfaces and upper surrounding rocks, rocks to be sheared Sample size is 70cmx70cmx70cm;

[0077] Step3: Prefabricated horizontal shear box and vertical load loading box: According to the appropriate size, use a relatively strong steel plate to weld a cuboid without a top cover, and weld a steel plate with a protruding central opening on one side steel plate, which is the horizontal shear Box-cut an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com