Sheet metal and sheet metal strip shearing system with variable speed feeding device

A metal strip and material feeding technology, which is applied to metal processing equipment, shearing devices, shearing machine equipment, etc., can solve the problems of severe fluctuations in the maneuvering load of flying shears, unfavorable length control accuracy, etc., and achieve the elimination of double length, The effect of sizing control model simplification and fast shearing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

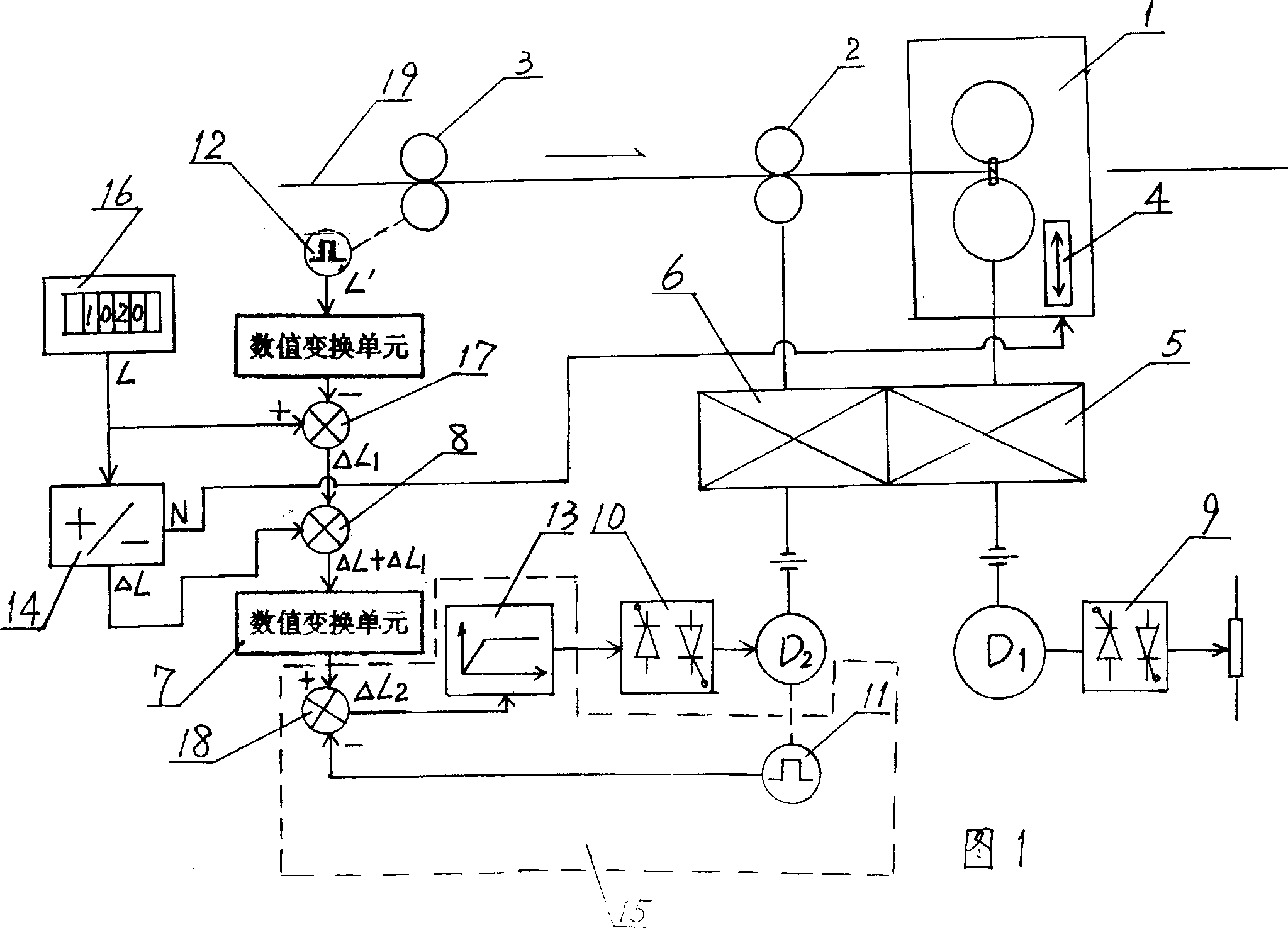

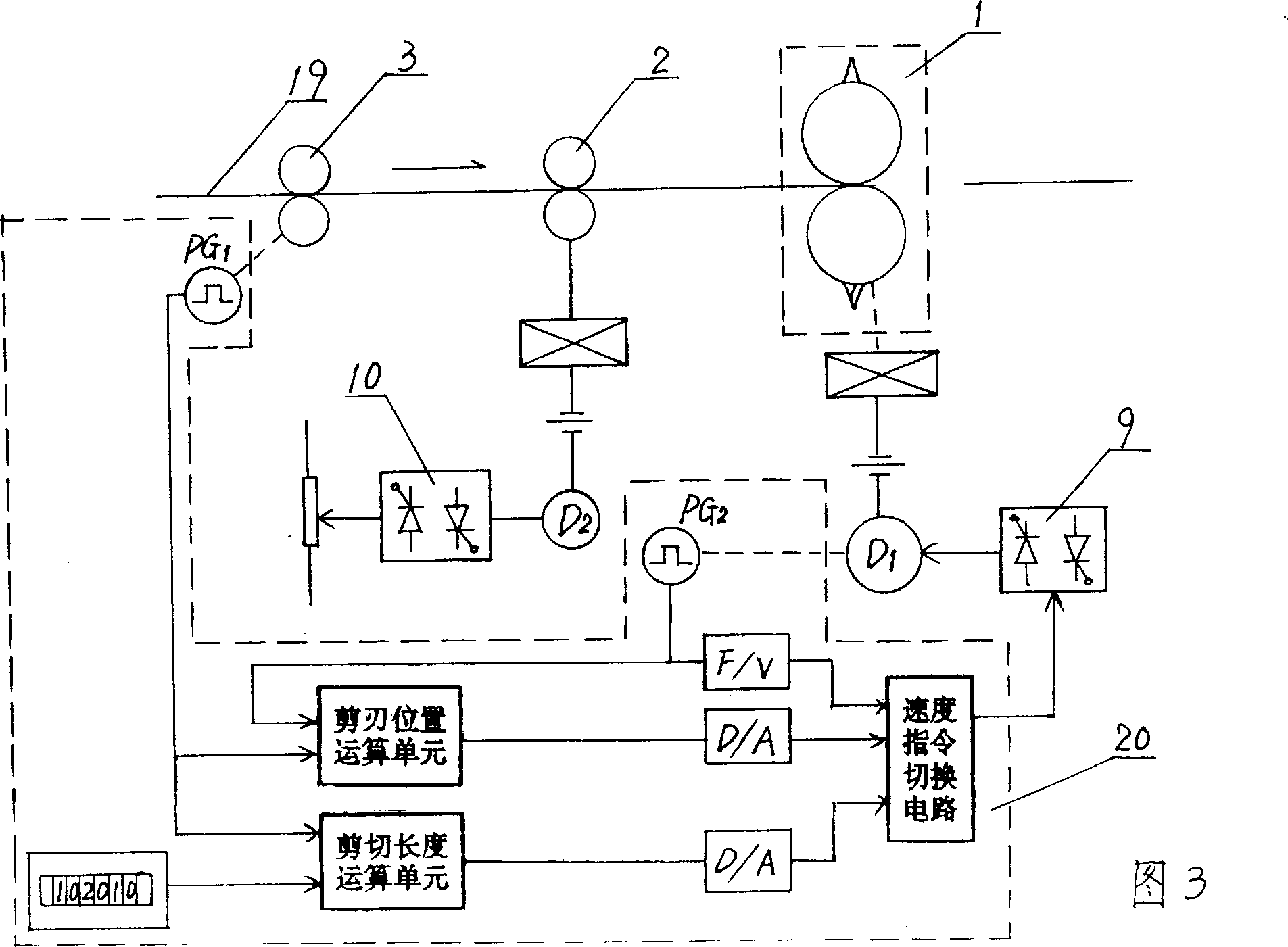

[0019] Referring to Fig. 1, this system comprises flying shear machine 1, feeding roller 2, measuring roller 3, dragging the motor D1 of flying shear machine operation and the driver 9 of motor D1, the adjustment motor D2 of feeding roller and the driver 10 of motor D2, main Transmission mechanism 5, differential mechanism 6 and electrical control system. The flying shear 1 has a definite rotary motion track and an air-cutting control mechanism 4, and its rotary motion track can be circular or non-circular.

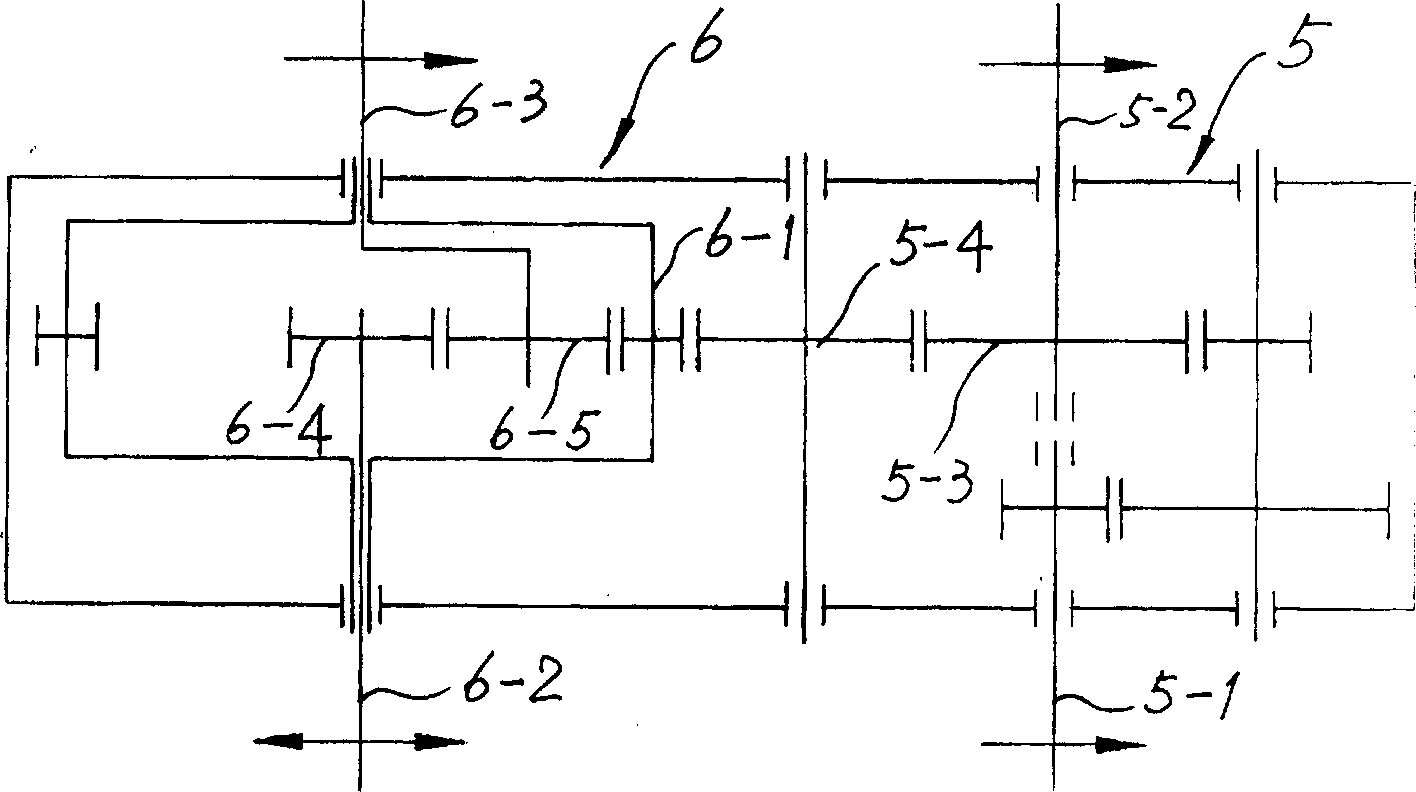

[0020] see figure 2 , the main transmission mechanism 5 adopts a common gear reducer, and the differential mechanism 6 adopts a typical planetary gear differential mechanism. The input end 5-1 of the gear reducer is connected to the motor D1, and its output end 5-2 is connected to the flying shear 1, and the output gear 5-3 of the gear reducer is used as a motion input member of the planetary gear differential mechanism , it meshes with the outer ring gear 6-1 in the pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap