A method for forming four large-capacity square batteries in series

A chemical formation method and battery chemical formation technology, applied in the direction of secondary batteries, secondary battery manufacturing, electrochemical generators, etc., can solve the constraints on the industrial application of square large-capacity batteries, increase battery manufacturing costs, and affect battery cycle life To achieve the effect of saving formation time and labor costs, improving various indicators, and improving formation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

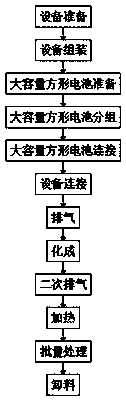

[0029] The present invention provides such figure 1 The method for forming four large-capacity square batteries in series includes the following steps:

[0030] Step 1. Equipment preparation: Prepare a flat plate with a rubber layer pasted on the top, an electric heating element inside and a vent hole running through it as a processing platform, and then prepare a battery forming machine, a gas pressure sensor and a temperature sensor installed inside. A hemispherical transparent sealing cover, a vacuuming device, an exhaust pipe, a wire connected to a socket and multiple groups of wires, each group of wires includes a wire connected to a plug, three ordinary wires , eight alligator clips;

[0031] Step 2. Equipment assembly: Connect the eight alligator clips in each group of wires to the wires connected to the plug and the two ends of the three ordinary wires, and then connect the wires connected to the socket to the battery forming machine in series, and vacuum the The equ...

Embodiment 2

[0044] The difference with above-mentioned embodiment 1 is:

[0045] Step 10. Heating: power on the electric heating element inside the processing platform and monitor the temperature between the transparent sealing cover and the processing platform in real time through the temperature sensor. The temperature between the transparent airtight cover and the processing platform reaches 45 degrees Celsius, so that the air therein is dried and the water vapor in the air is eliminated.

Embodiment 3

[0047] Different from above-mentioned embodiment 1 and embodiment 2 is:

[0048] Step 10. Heating: power on the electric heating element inside the processing platform and monitor the temperature between the transparent sealing cover and the processing platform in real time through the temperature sensor. The temperature between the transparent airtight cover and the processing platform reaches 48 degrees Celsius, so as to dry the air therein and eliminate the water vapor in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com