A lithium-ion battery series closed-port formation equipment

A lithium-ion battery and chemical forming equipment technology, applied in the field of lithium-ion battery series closed forming equipment, can solve the problems of difficult to control product consistency, waste of aluminum-plastic film, cumbersome forming steps, etc. Bottleneck, the effect of simplifying the formation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

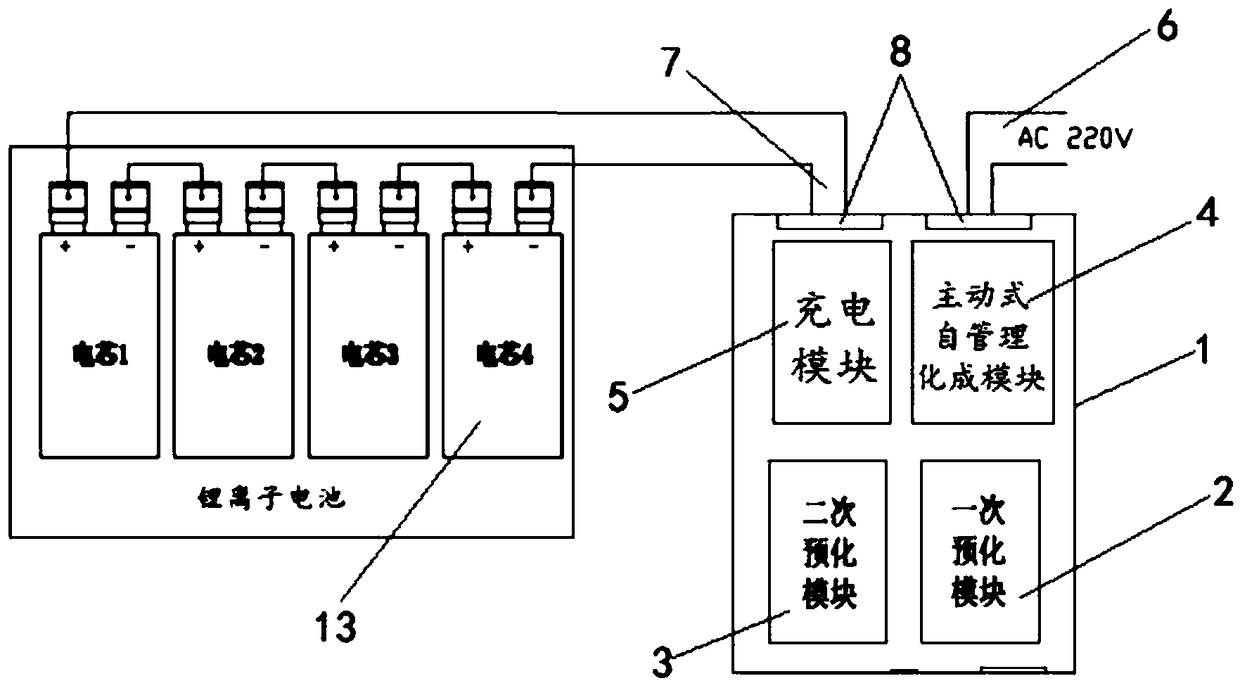

[0018] see Figure 1 to Figure 2 , a lithium-ion battery formation equipment of the present invention, comprising a box body 1, a primary pre-chemical module 2, a secondary pre-chemical module 3, an active self-management chemical formation module 4 and a charging module 5, the primary pre-chemical module 2, the secondary The secondary pre-chemical module 3, the active self-management conversion module 4 and the charging module 5 are arranged in the box body 1, and the primary pre-chemical module 2 is used to decompose the H in the lithium-ion battery 2 O, H 2 O is converted into irreversible hydrogen atoms H and oxygen atoms O, the cut-off voltage range of pre-chemicalization is 2.5-2.6V, and the maximum value of pre-chemical current is 0.01CA, thus preventing water from decomposing into hydrogen and oxygen during the chemical formation process, making it impossible A complex chemical reaction with the electrolyte ensures the safety of the production and use of lithium-ion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com