Formation method of lithium ion battery

A lithium-ion battery and formation method technology, which is applied in the field of formation of lithium-ion batteries, can solve the problems of difficult to balance high-temperature and low-temperature performance, the use temperature window is not very wide, and the high-temperature capacity retention rate is poor, so as to shorten the formation time, Effects of improving cycle performance and simplifying chemical synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

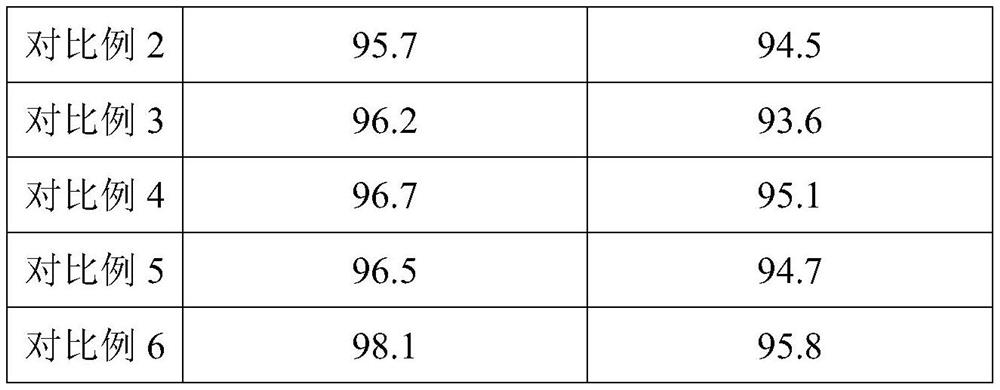

Examples

Embodiment 1

[0027] 1) The electrolyte is injected into the battery to be injected, and the electrolyte includes linear carbonates and cyclic carbonates, electrolyte salts and additives; the linear carbonates account for 50% of the total electrolyte volume, and the rest are cyclic carbonates. Carbonate; wherein the additives include fluoroethylene carbonate, divinyl sulfone and α, α-dimethyl-γ-butyrolactone, wherein the volume concentration of the additive satisfies the following relationship, (volume of fluoroethylene carbonate concentration+α, the volume concentration of α-dimethyl-γ-butyrolactone)*the volume of linear carbonate=k*divinyl sulfone*the volume of cyclic carbonate, wherein k=1.62; the fluorinated The volume concentration of ethylene carbonate: α, the volume concentration of α-dimethyl-γ-butyrolactone=1:1.6, the volume concentration of described divinyl sulfone is 2.4%, the volume concentration of fluoroethylene carbonate is 1.50%, the volume concentration of α,α-dimethyl-γ-b...

Embodiment 2

[0035] 1) Inject the electrolyte into the battery to be injected, the electrolyte includes linear carbonate and cyclic carbonate, electrolyte salt and additives; the linear carbonate accounts for 55% of the total electrolyte volume, and the rest is ring Carbonate; wherein the additives include fluoroethylene carbonate, divinyl sulfone and α, α-dimethyl-γ-butyrolactone, wherein the volume concentration of the additive satisfies the following relationship, (volume of fluoroethylene carbonate concentration+α, the volume concentration of α-dimethyl-γ-butyrolactone)*the volume of linear carbonate=k*divinyl sulfone*the volume of cyclic carbonate, wherein k=1.65; the fluorinated The volume concentration of ethylene carbonate: α, the volume concentration of α-dimethyl-γ-butyrolactone=1:1.6, the volume concentration of described divinyl sulfone is 2.6%, the volume concentration of fluoroethylene carbonate is 1.35%, the volume concentration of α,α-dimethyl-γ-butyrolactone is 2.16%;

[...

Embodiment 3

[0043] 1) The electrolyte is injected into the battery to be injected, and the electrolyte includes linear carbonates and cyclic carbonates, electrolyte salts and additives; the linear carbonates account for 50% of the total electrolyte volume, and the rest are cyclic carbonates. Carbonate; wherein the additives include fluoroethylene carbonate, divinyl sulfone and α, α-dimethyl-γ-butyrolactone, wherein the volume concentration of the additive satisfies the following relationship, (volume of fluoroethylene carbonate concentration+α, the volume concentration of α-dimethyl-γ-butyrolactone)*the volume of linear carbonate=k*divinyl sulfone*the volume of cyclic carbonate, wherein k=1.64; the fluorinated The volume concentration of ethylene carbonate: α, the volume concentration of α-dimethyl-γ-butyrolactone=1:1.6, the volume concentration of described divinyl sulfone is 2.5%, the volume concentration of fluoroethylene carbonate is 1.58%, the volume concentration of α,α-dimethyl-γ-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com