Production method and device of a surgical gown

A production method and production device technology, applied in the field of clothing production, can solve the problems of large number of workers, low production efficiency of surgical gowns, and high labor costs, and achieve the effects of high degree of automation, low cost, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

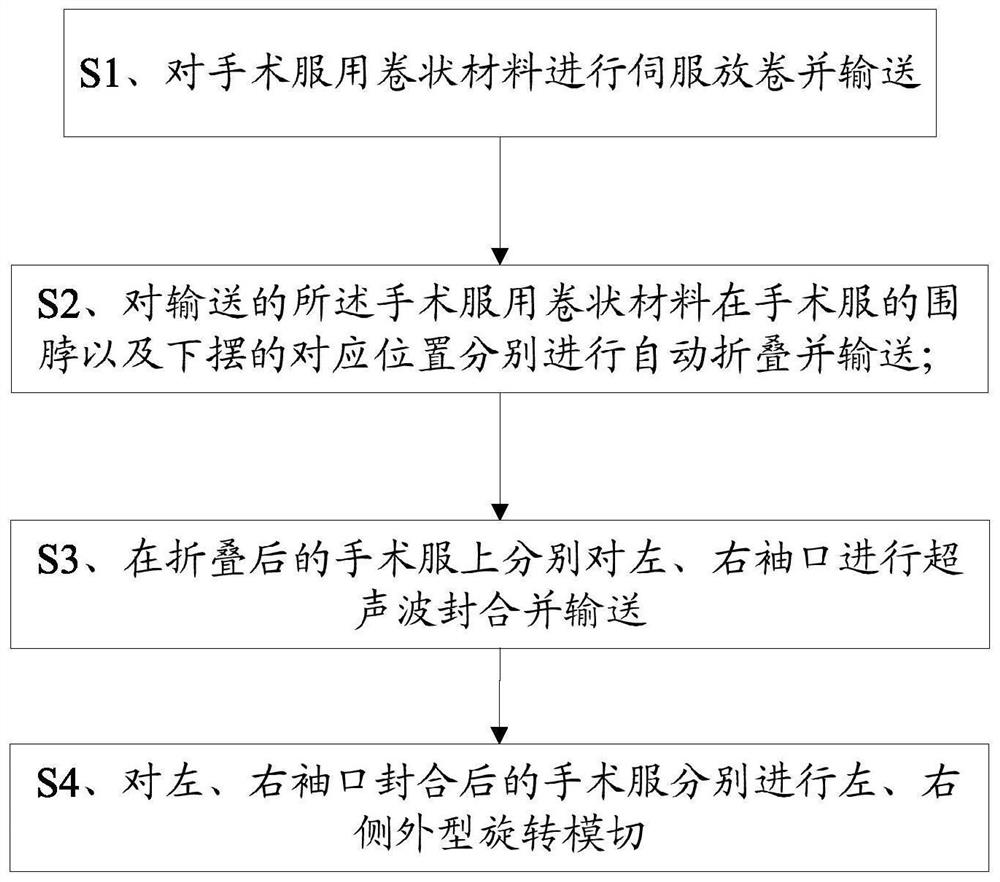

[0057] Please refer to figure 1 , a production method of a surgical gown, comprising the steps of:

[0058] S1. Servo unwinding and conveying the roll material for surgical use;

[0059] In the process of unwinding the roll material for surgical wear, the tension of the surgical wear material is detected, and the speed of servo unwinding of the roll material for surgical wear is controlled according to the tension. Specifically, a tension threshold can be set , when the detected tension exceeds the tension threshold, the speed of servo unwinding of the surgical material is adjusted by sending a signal;

[0060] S12, carry out virtual incision and tear line at the neck of the surgical gown for the delivered surgical material;

[0061] In addition, in the process of virtual cutting, roll cutting of the bib incision is also performed at the bib, such as Image 6 As shown, 91 is the scarf tear line, and 95 is the scarf incision;

[0062] S2. Automatically fold and transport th...

Embodiment 2

[0069] The difference between this embodiment and the first embodiment is that the adjacent surgical gowns on the surgical wearing material are in opposite directions and cross-aligned. For details, please refer to Figure 7 , by performing positive and negative buckle and cross layout on the adjacent surgical clothing on the surgical wearing material, it is possible to make full use of the remaining material after cutting out one surgical clothing on the surgical wearing material, and two adjacent surgical clothing There are overlapping parts of materials, thereby improving the utilization rate of surgical materials.

Embodiment 3

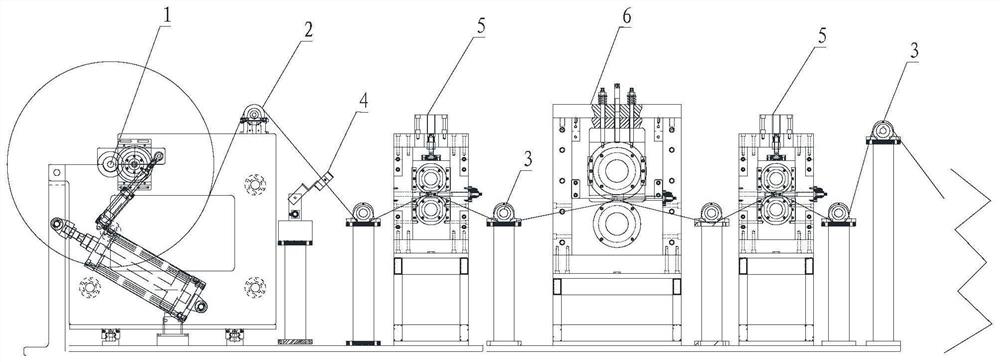

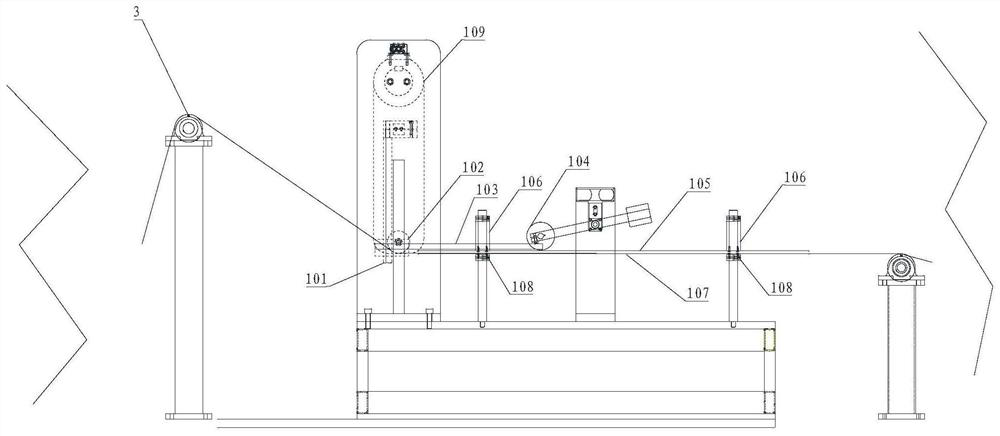

[0071] Please refer to Figure 2 to Figure 5 , a production device for surgical gowns, including an automatic feeding device, a servo unwinding device 1, a servo motor, a feeding device 3, a folding device, a sealing device 7 and an external rotary roller cutting device 8;

[0072] The automatic feeding device is connected with the servo unwinding device 1, and the automatic feeding device transports the roll material for surgical wear to the servo unwinding device 1. Preferably, the servo unwinding device 1 is a magnetic powder unwinding device;

[0073] Among them, the automatic feeding device transports the roll-shaped material for surgical wear from the ground, the feeding tray or the feeding rack to the servo unwinding device 1;

[0074] The servo unwinding device 1 is connected with the servo motor, and the servo motor drives the servo unwinding device to release the surgical wear roll material;

[0075] The servo motor, the folding device, the sealing device 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com