Z type CdS-Ag-TiO2 composite photocatalytic material and preparation method and application thereof

A cds-ag-tio2, composite photocatalysis technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced redox ability and failure to completely solve photocorrosion, etc. Achieve the effect of maintaining chemical stability, reducing photocorrosion, and improving photocatalytic hydrogen production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

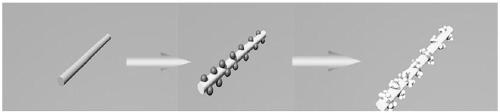

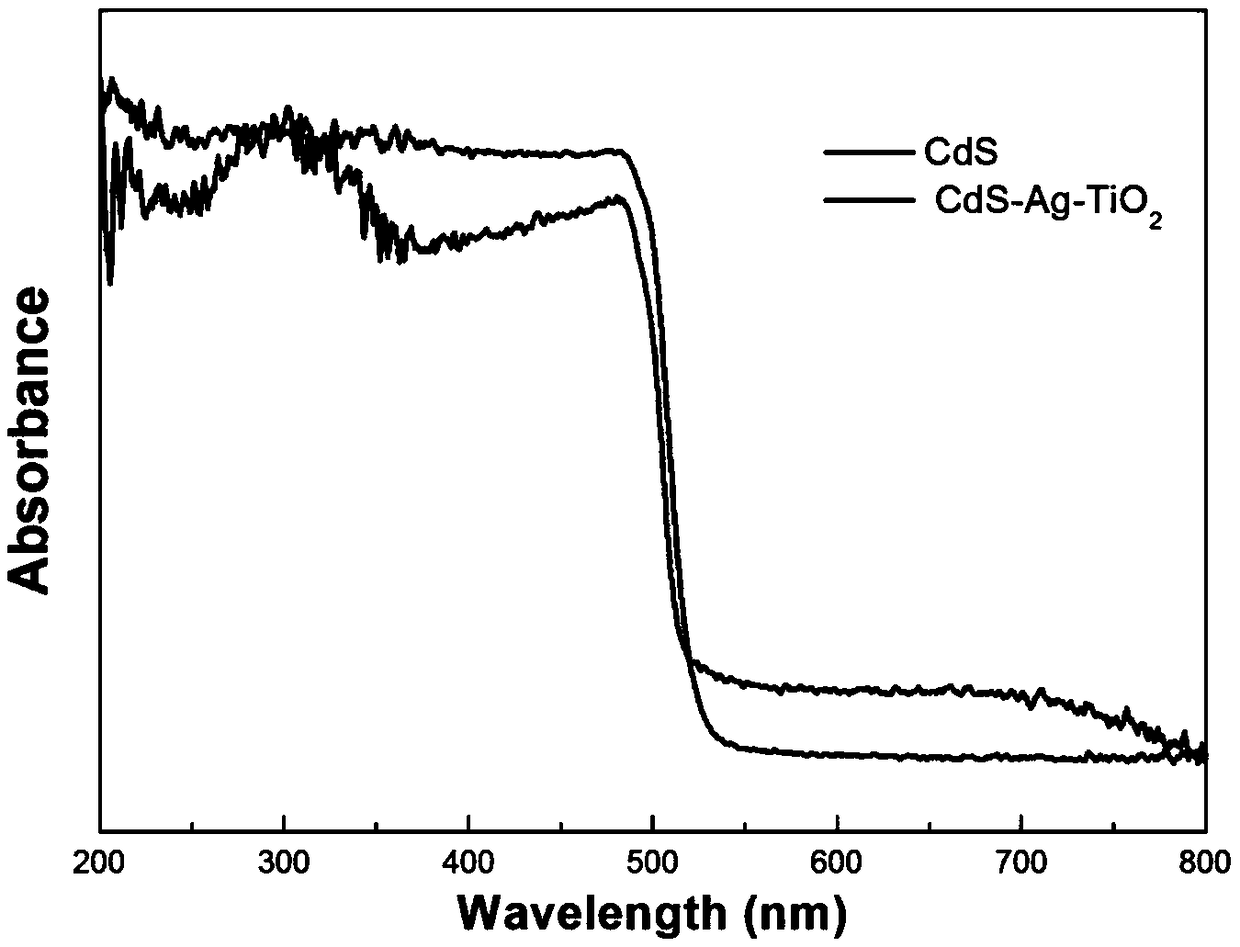

[0032] A Z-type CdS-Ag-TiO 2 The preparation method of composite photocatalytic material comprises the steps:

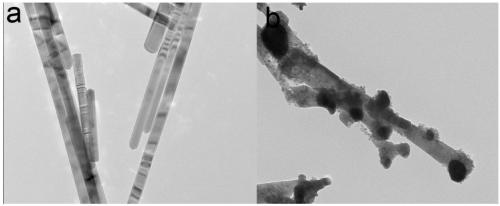

[0033] 1. Synthesis of CdS nanowires

[0034] Add 2 mL of n-dodecanethiol to 18 mL of ethylenediamine solution. After ultrasonic fusion, add 1 mmol of precursor cadmium acetate, and ultrasonically disperse to a transparent solution. Then, add 1 mmol of sodium sulfide, react in a polytetrafluoroethylene reactor at 180° C. for 24 to 48 hours; after cooling to room temperature, directly wash the precipitate with acetone and absolute ethanol to obtain CdS nanowires.

[0035] 2. Photoreduction synthesis of CdS-Ag

[0036] Add 20 mg of silver nitrate to 3 mL of water, and then dissolve the CdS nanowires prepared in step 1 in 97 mL of ultrapure water; then add the silver nitrate solution dropwise to the CdS nanowires and stir for 5 min; then, use a xenon lamp The mixed solution was irradiated for 30 minutes to achieve the purpose of photoreduction, and CdS-Ag was prepare...

Embodiment 2

[0044] A Z-type CdS-Ag-TiO 2 The preparation method of composite photocatalytic material comprises the steps:

[0045] 1. Synthesis of CdS nanowires

[0046] Add 1 mL of n-dodecanethiol to 19 mL of ethylenediamine solution, ultrasonically fuse, then add 1 mmol of precursor cadmium acetate, and ultrasonically disperse to a transparent solution. Then, add 2 mmol of sodium sulfide, react in a polytetrafluoroethylene reactor at 180° C. for 24 to 48 hours; after cooling to room temperature, directly wash the precipitate with acetone and absolute ethanol to obtain CdS nanowires.

[0047] 2. Photoreduction synthesis of CdS-Ag

[0048] Add 20 mg of silver nitrate to 4 mL of water, and then dissolve the CdS nanowires prepared in step 1 in 96 mL of ultrapure water; then add the silver nitrate solution dropwise to the CdS nanowires and stir for 5 min; then, use a xenon lamp The mixed solution was irradiated for 30 minutes to achieve the purpose of photoreduction, and CdS-Ag was prepar...

Embodiment 3

[0052] A Z-type CdS-Ag-TiO 2 The preparation method of composite photocatalytic material comprises the steps:

[0053] 1. Synthesis of CdS nanowires

[0054] Add 2 mL of n-dodecanethiol to 18 mL of ethylenediamine solution. After ultrasonic fusion, add 1 mmol of precursor cadmium acetate, and ultrasonically disperse to a transparent solution. Then, add 2 mmol of sodium sulfide, react in a polytetrafluoroethylene reactor at 180° C. for 24 to 48 hours; after cooling to room temperature, directly wash the precipitate with acetone and absolute ethanol to obtain CdS nanowires.

[0055] 2. Photoreduction synthesis of CdS-Ag

[0056] Add 20 mg of silver nitrate to 5 mL of water, and then dissolve the CdS nanowires prepared in step 1 in 95 mL of ultrapure water; then add the silver nitrate solution dropwise to the CdS nanowires and stir for 5 min; then, use a xenon lamp The mixed solution was irradiated for 30 minutes to achieve the purpose of photoreduction, and CdS-Ag was prepare...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap