Energy-saving stirring type building sand stone impurity removal box

A stirring and miscellaneous box technology, applied in the cleaning method of tools, solid separation, sieve, etc., can solve the problems of affecting the quality of sand and gravel, waste of energy, incomplete removal of impurities from sand and gravel, etc. Clean, achieve the effect of reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

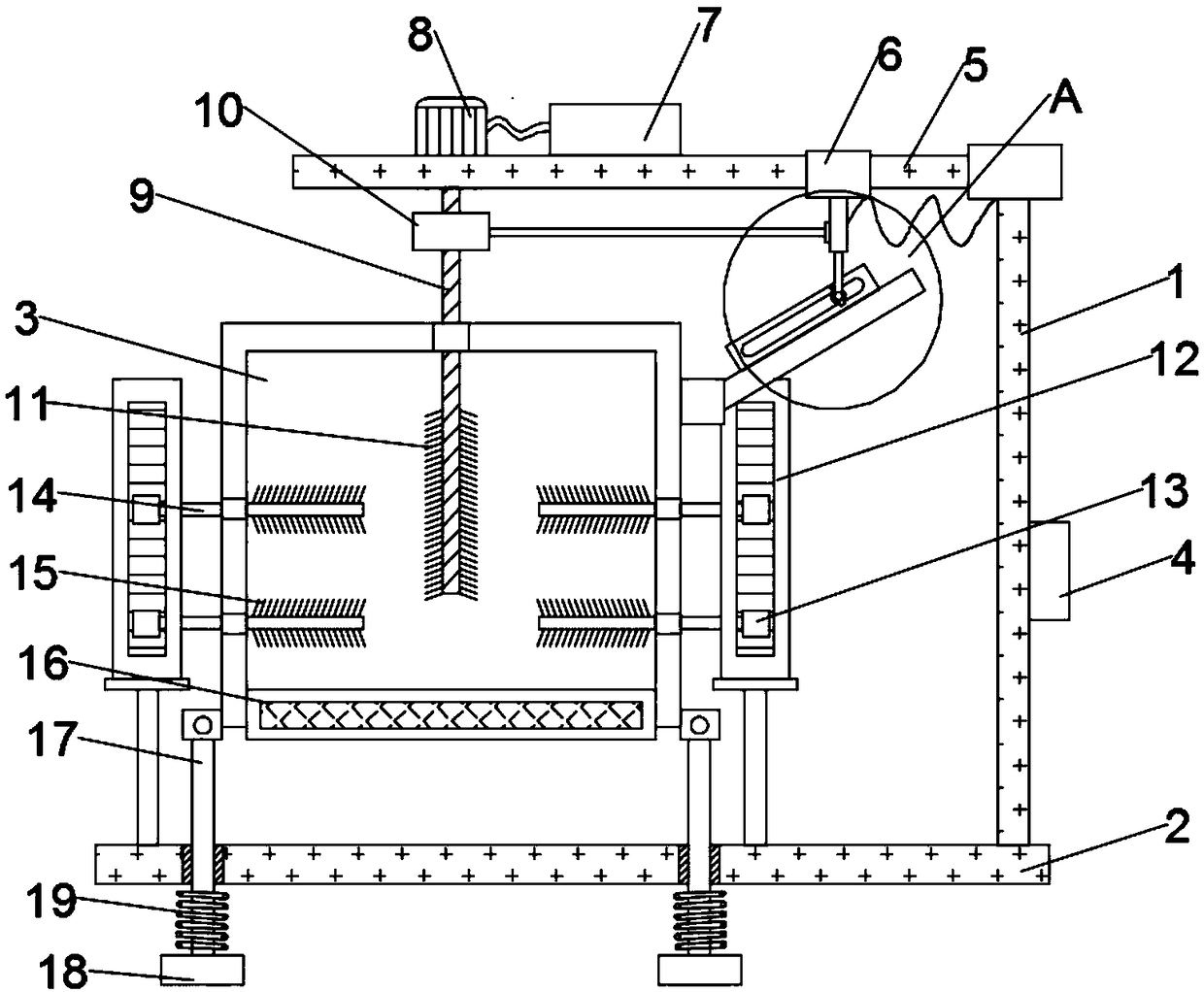

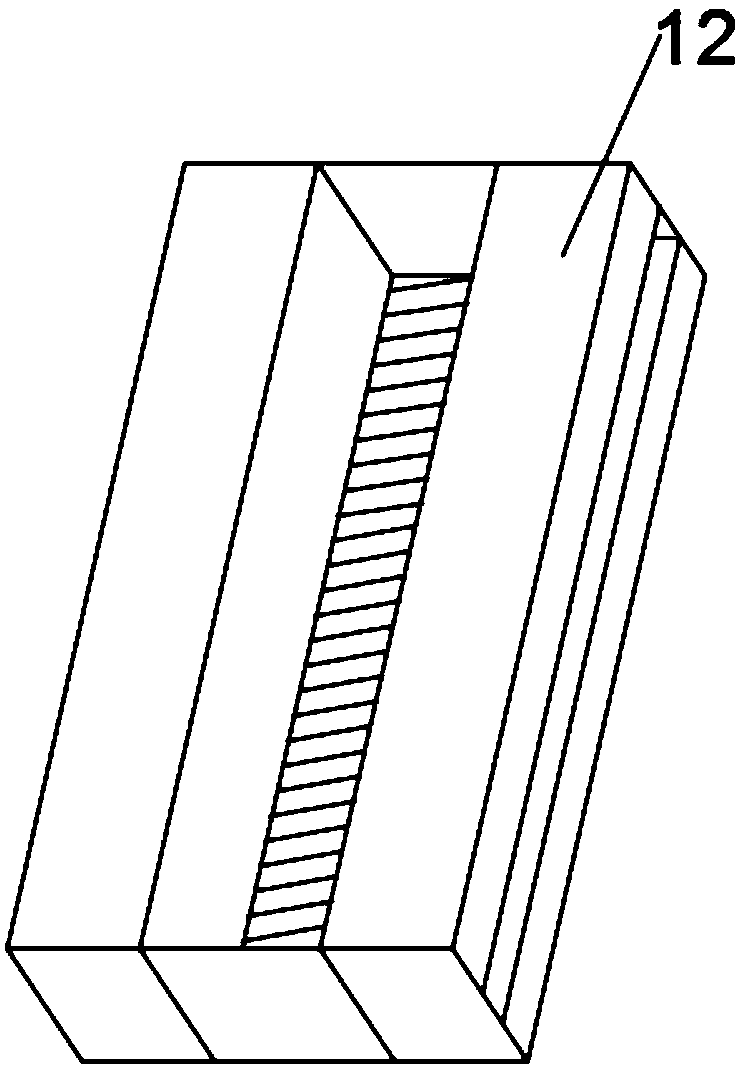

[0019] see Figure 1~3 , in an embodiment of the present invention, an energy-saving stirring type building sand and stone removal box includes a removal box 3, a removal assembly and a drive assembly, the removal assembly is installed in the removal box 3, and the drive assembly is arranged on the removal Above the box 3, the impurity removal assembly includes a vertical brush 11 arranged in the middle of the impurity removal box 3 and a horizontal brush 15 evenly distributed on both side walls of the impurity removal box 3, and the horizontal hair brush 15 is fixedly welded On the second rotating shaft 14, the vertical hairbrush 11 cooperates with the horizontal hairbrush 15 to sweep away the impurities on the surface of the gravel, and the bottom of the dust removal box 3 is provided with a filter screen 16 for filtering impurities. The side walls of the upper cross bar 5 are clamped on both sides, and the miscellaneous removal box 3 is slidingly connected with the bottom p...

Embodiment 2

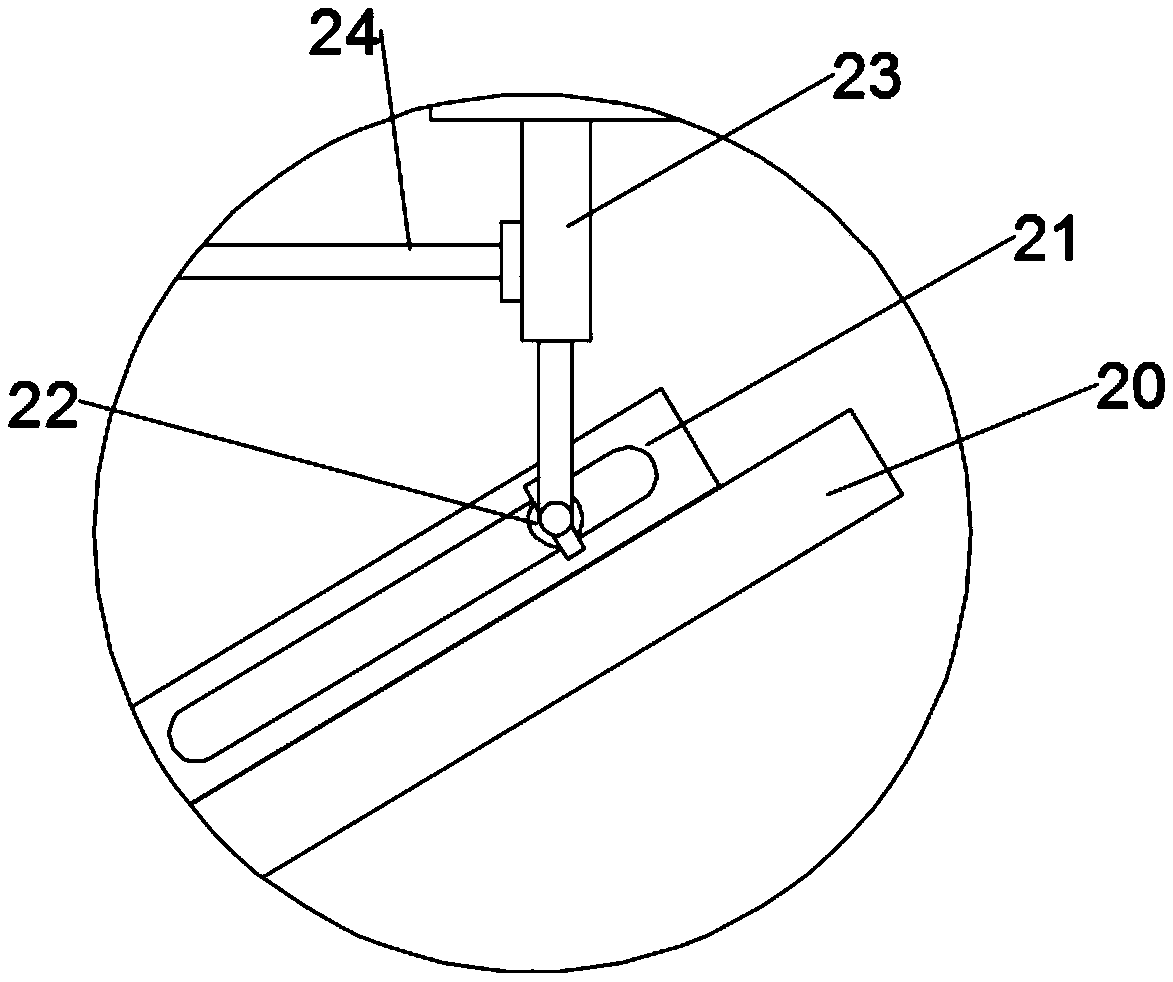

[0025] see Figure 4 , in this embodiment, the take-up wheel 10 is replaced by the second gear 26, the working motor 8 is not provided, and the return spring is replaced by a hydraulic cylinder, the front side of the take-up wheel 10 is provided with a horizontal rack 25, and the horizontal rack 25 is fixedly welded to the connecting rod 23, and the hydraulic cylinder is electrically connected to the PLC controller 4 and the storage battery 7 respectively. Through the operation of the hydraulic cylinder, the connecting rod 23 can be driven to slide left and right, while the horizontal rack 25 drives the first rotating shaft 9 to rotate. It can also play the effect of cleaning sand and gravel, and this embodiment can also play the role of energy saving and efficient impurity removal, and other structures in this embodiment are the same as those of Embodiment 1.

[0026] The working principle of the present invention is: start the driving assembly by controlling the PLC controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com