Paper-covered copper strap wire bending tool

A copper flat wire and paper-wrapped technology, which is applied in the field of paper-wrapped copper flat wire bending tools, can solve problems such as the difficulty of bending wide and flat paper-wrapped copper flat wires, and achieve the effect of simplifying operations and avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

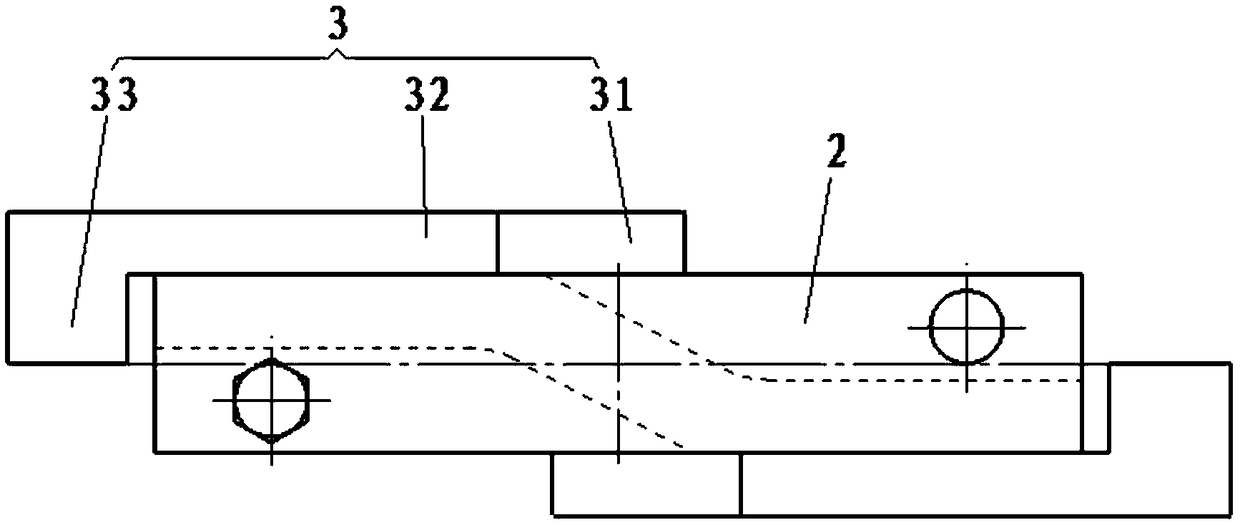

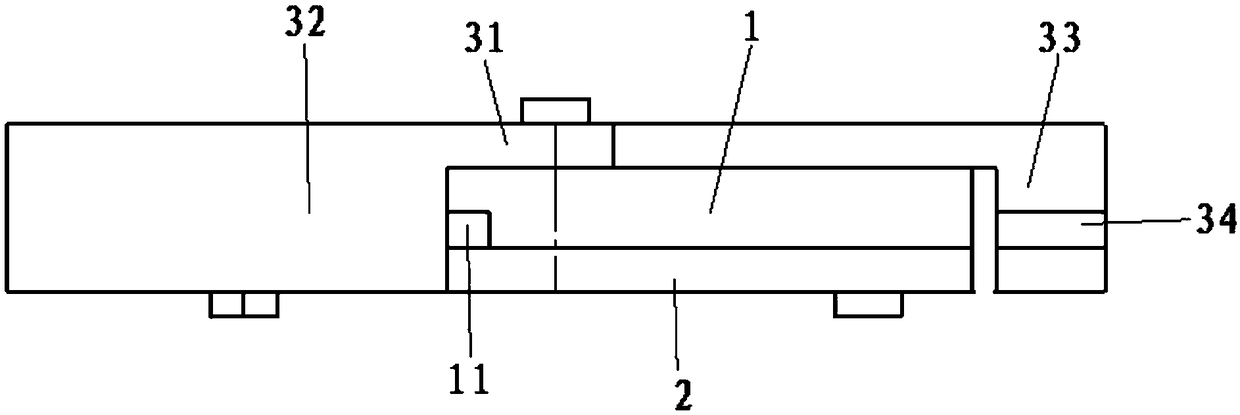

[0017] Such as figure 2 , image 3 and Figure 5 As shown: the paper-clad copper flat wire bending tool includes a mother board 1 and a cover board 2; the front of the mother board 1 is provided with a wire groove 11, and the wire groove 11 includes a first horizontal groove 112, a second horizontal groove 113 and a chute 111 , the chute 111 is located in the middle of the motherboard 1, the first transverse groove 112 and the second transverse groove 113 are arranged along the length direction of the motherboard 1 and are respectively located on the two side edges of the motherboard 1, the first transverse groove 112 and the second transverse groove 113 Respectively extend from both ends of the motherboard 1 to the chute 111; the cover 2 is attached to the front of the motherboard 1 and covers the wire groove 11, the cover 2 and the motherb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com