A high-altitude cable installation mechanism with pre-tightening function

A high-altitude cable and installation mechanism technology, applied in the direction of cable suspension devices, overhead lines/cable equipment, etc., can solve problems such as heavy, unfavorable cable stability, and difficult tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

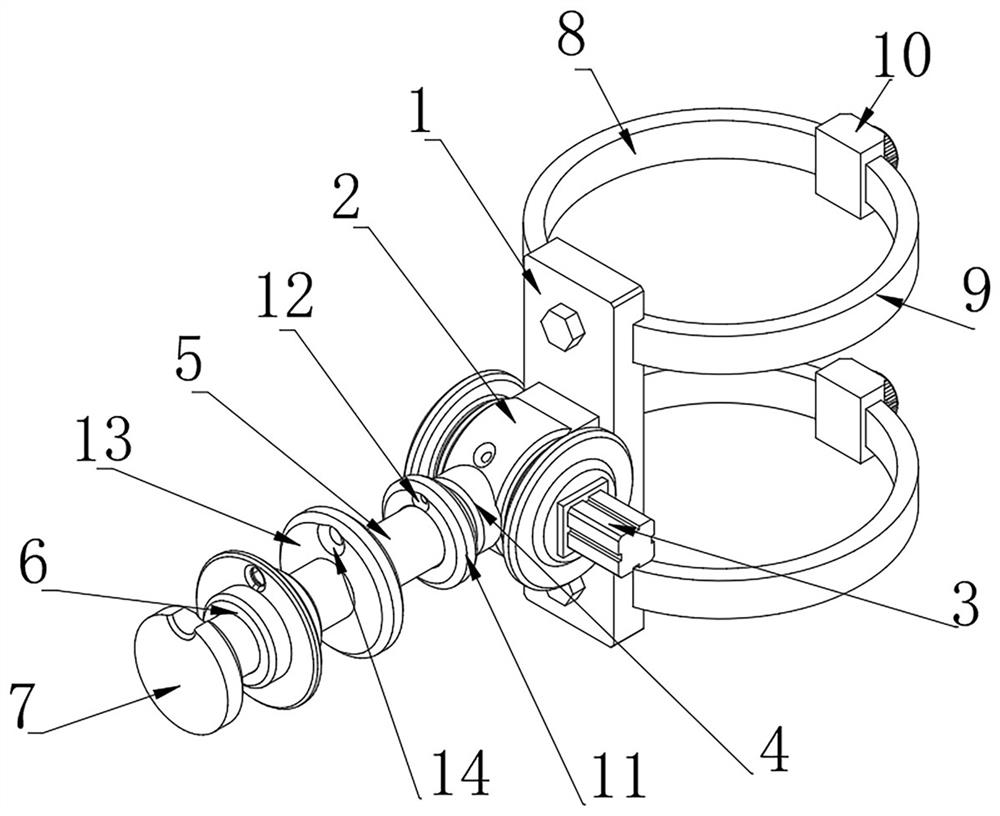

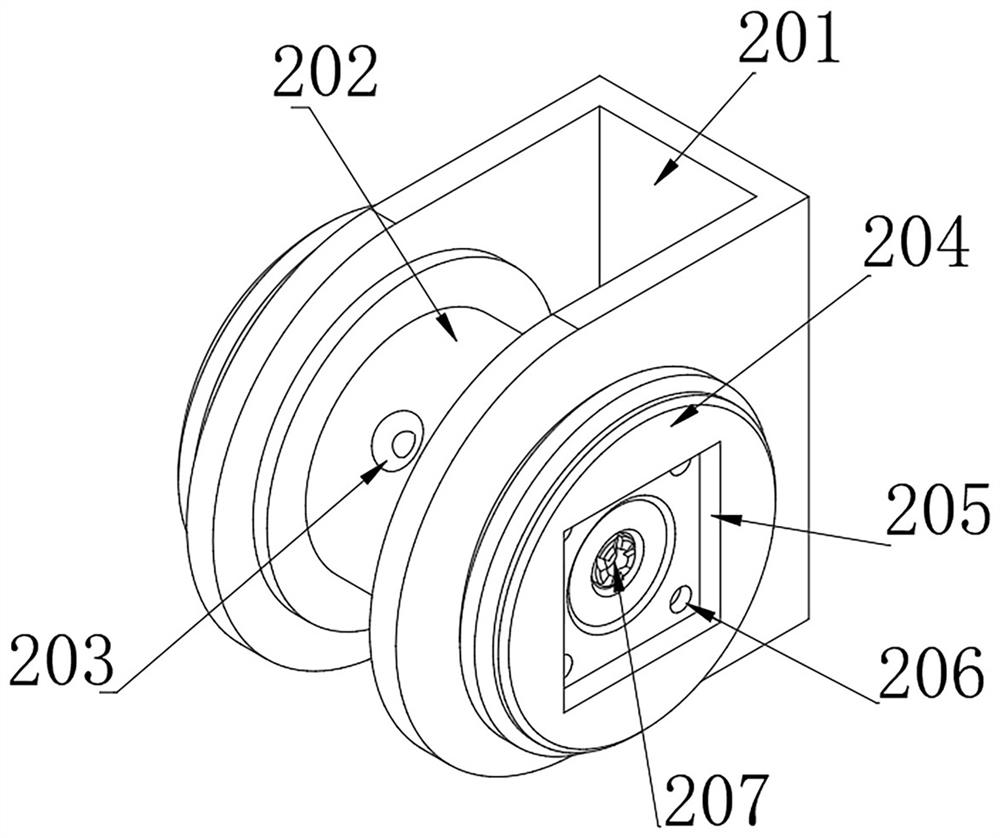

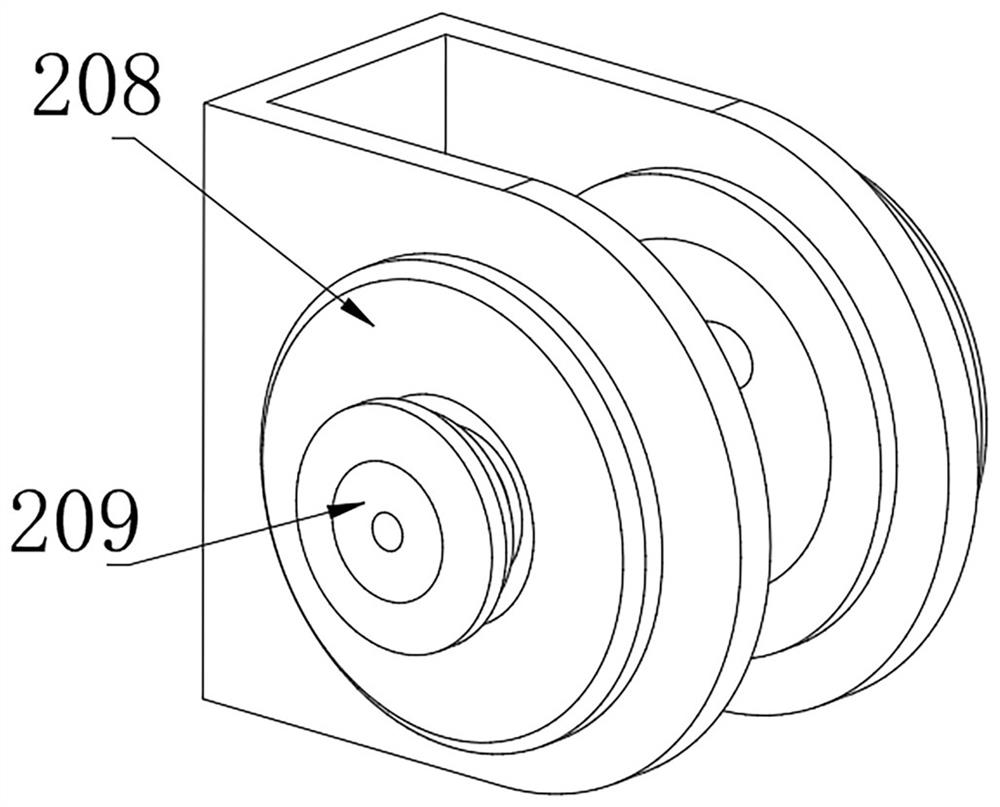

[0035] like Figures 1 to 12 As shown, the embodiment of the present invention provides a high-altitude cable installation mechanism with a pre-tightening function, including an installation plate 1, and an end lock assembly 2 is fixedly installed at the front end of the installation plate 1, and the end lock assembly 2 A No. 1 motor 3 is provided on one side surface, a No. 2 motor 4 is fixedly installed at the front end of the end lock assembly 2, a winding sleeve 5 is fixedly connected to the front end of the No. 2 motor 4, and the front end of the winding sleeve 5 is fixed The No. 2 tightening plate 13 is rotatably arranged, the front end of the No. 2 tightening plate 13 is fixedly connected with a force relief assembly 6, the front end of the force relief assembly 6 is fixedly installed with a lead 7, and the upper end of the winding sleeve 5 is fixed. A No. 1 tightening plate 11 is coaxially fixedly connected, and two No. 1 fixing rings 8 and two No. 2 fixing rings 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com