High-elasticity polymer material equipment

A polymer material and high-elasticity technology, applied in the field of multi-color rubber, can solve the problems of long time-consuming, inconvenient quantitative discharge of multi-color rubber formula raw materials, uneven mixing, etc., to improve uniformity, increase mixing efficiency, Effect of Reducing Mixing Proportioning Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

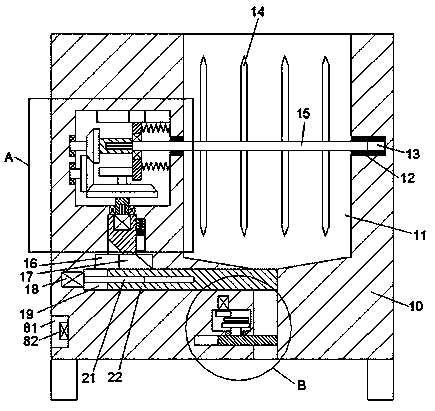

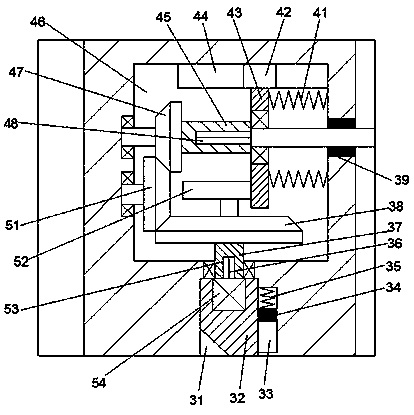

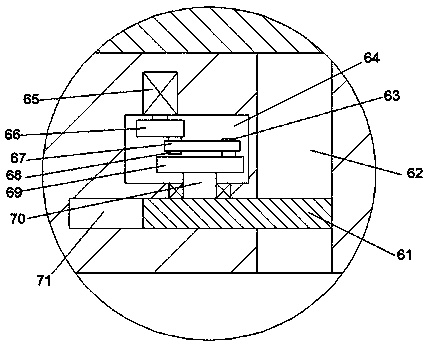

[0016] Combine below Figure 1-3 The present invention will be described in detail.

[0017] refer to Figure 1-3 , a high elastic polymer material device according to an embodiment of the present invention, including a base 10, a mixing chamber 11 is provided in the top end surface of the base 10, and the base on the left side of the mixing chamber 11 10 is provided with a first conduction chamber 46, and a rotating main shaft 15 is installed between the conducting chamber 46 and the mixing chamber 11 with a gap. The right side wall of the stirring chamber 11 is opposite to the rotating main shaft 15 with a slot 13, the rotating main shaft 15 extends into the slot 13, the rotating main shaft 15 extends into the first conduction chamber 46 and the outer circumference A push plate 43 is installed in rotation fit, and a guide slide plate 42 is fixed on the top end surface of the push plate 43, and the guide slide plate 42 is slidably fitted in a slide rail 44, and the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com