Inverse-magnetostrictive central axle torque sensor

A technology of inverse magnetostriction and magnetostriction, which is applied in the field of sensors, can solve the problems of installation and use, restrict the popularization and application of torque sensors, and poor versatility, and achieve the effect of improving the degree of versatility, ideal versatility, and simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

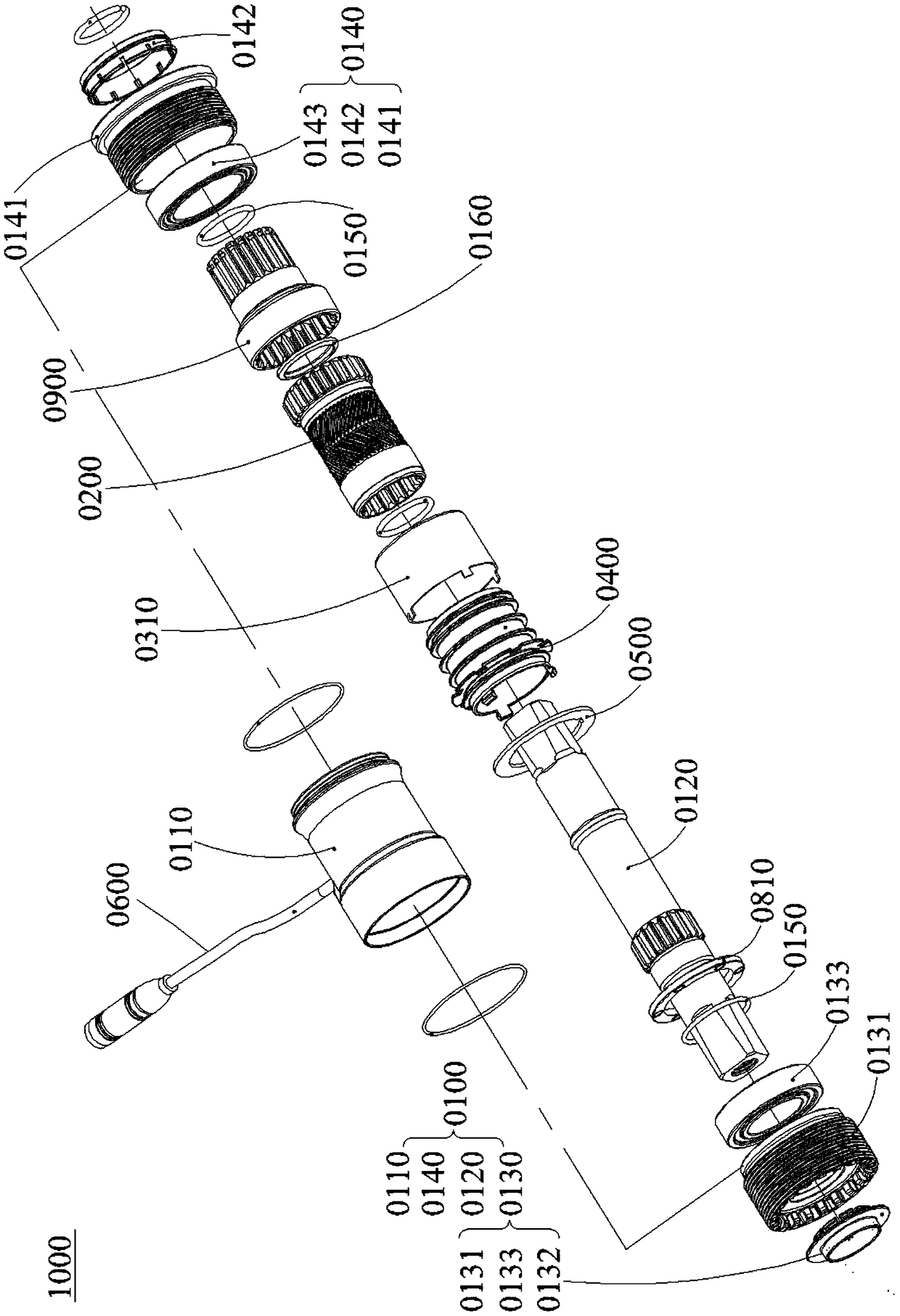

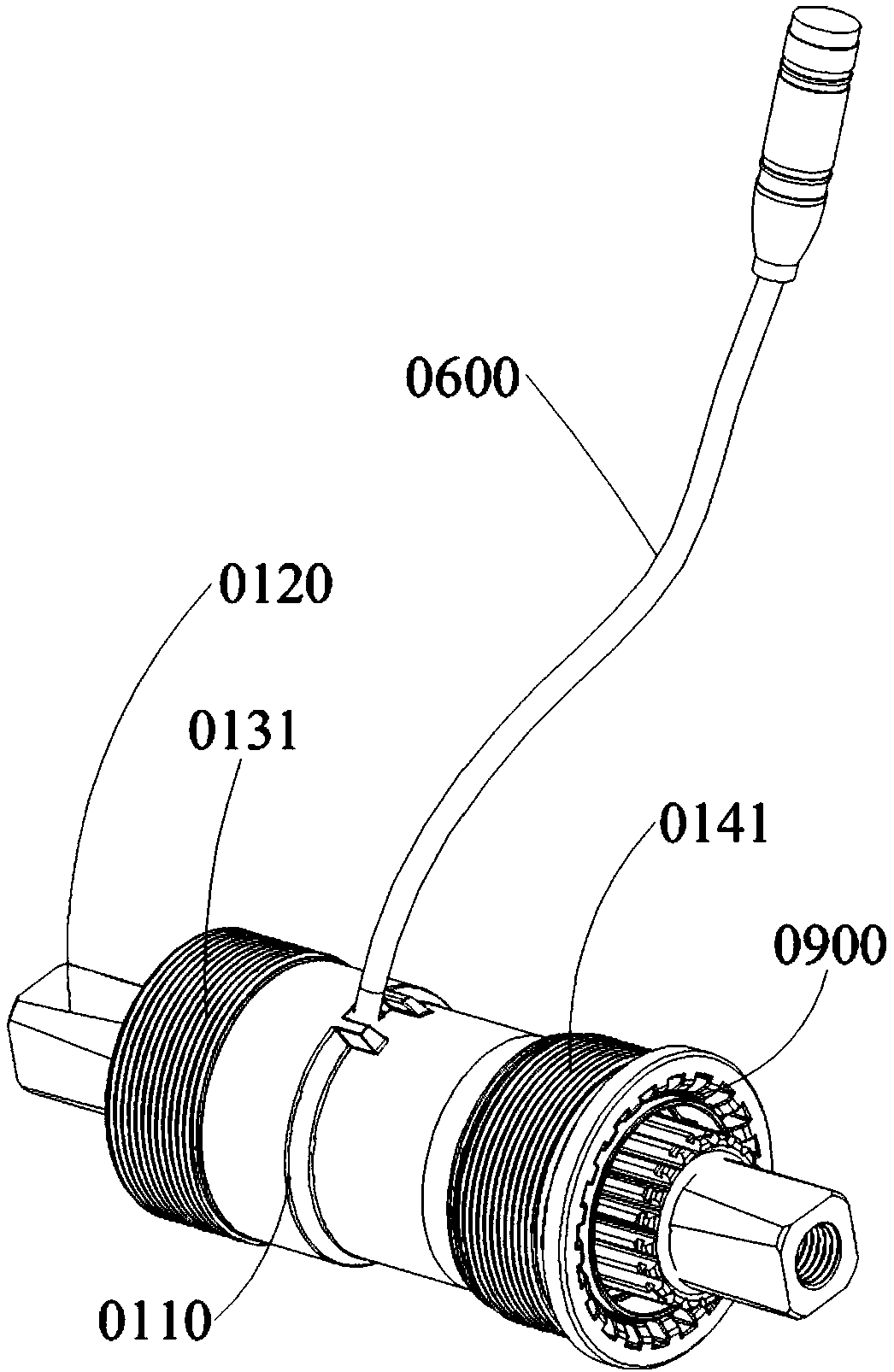

[0040] see figure 1 , this embodiment discloses an inverse magnetostrictive central axis torque sensor 1000, including a central axis 0100, a strain sleeve 0200 and an induction coil 0300, which are used for direct installation and application on existing general structures, providing ideal sensitivity and Sensing accuracy.

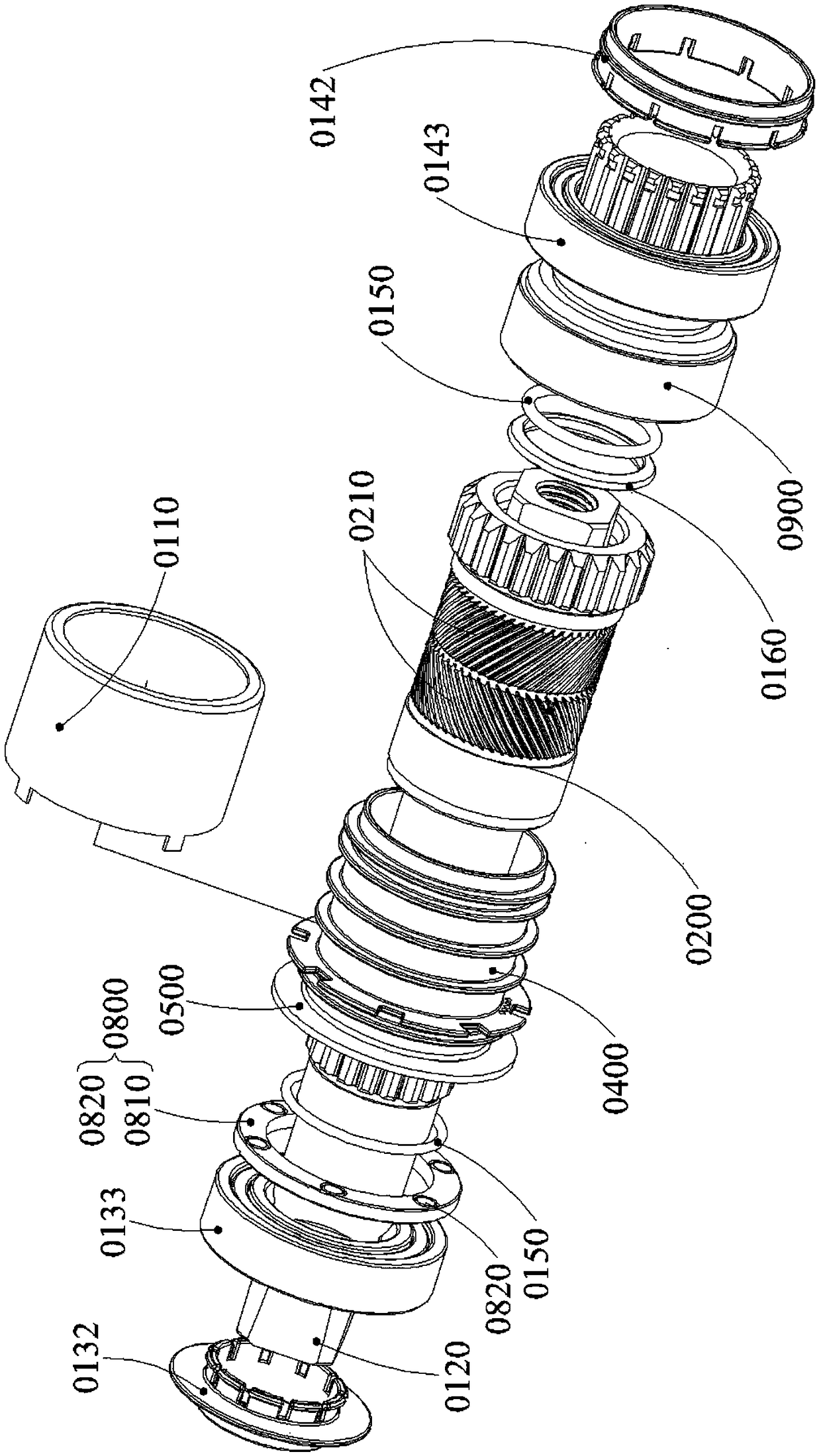

[0041] Please refer to Figure 2~4 , the central shaft 0100 includes a shaft sleeve 0110, a first end assembly 0130, a second end assembly 0140 and a mandrel 0120, the four surround and form an annular accommodation space for accommodating and installing other structural components. Wherein, the first end assembly 0130 and the second end assembly 0140 are respectively closed at both ends of the shaft sleeve 0110, and the mandrel 0120 rotatably passes through the shaft sleeve 0110, the first end assembly 0130 and the second end assembly 0140 in sequence .

[0042] Please refer to Figure 4 and Figure 6, the shaft sleeve 0110, the first end assembly 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com