Anti-sticking and non-extrusion brown sugar quantitative sorting machine

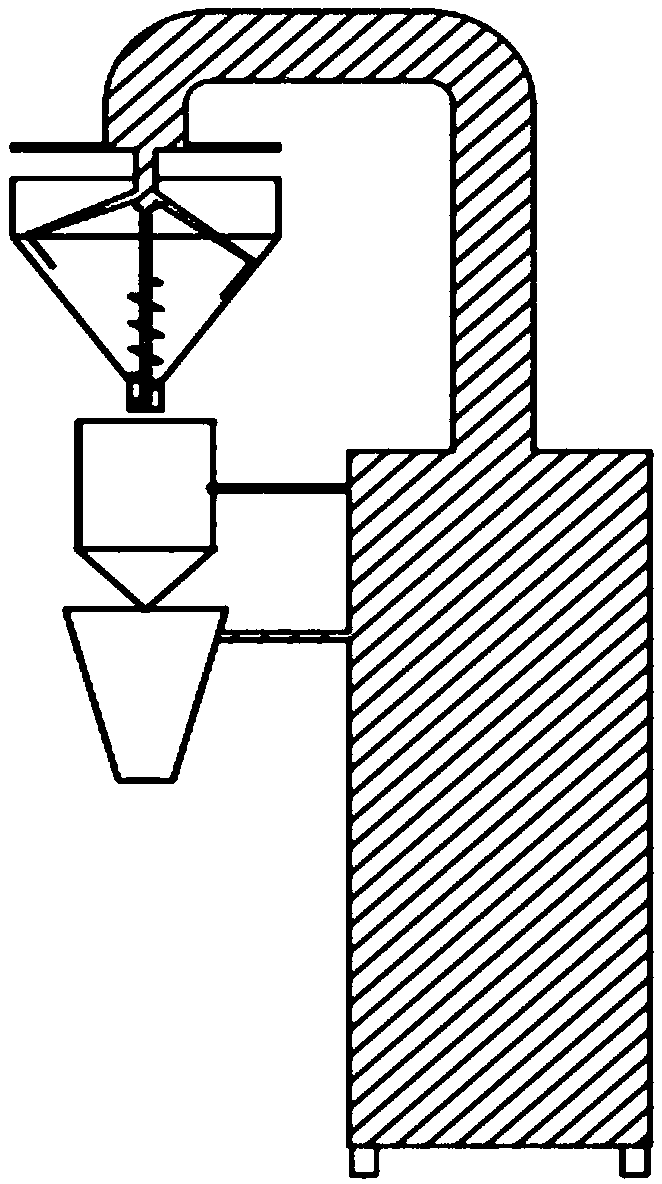

An anti-sticking and packaging machine technology, applied in packaging and other directions, can solve the problems of sticky machines and equipment, inaccurate measurement accuracy, etc., and achieve the effects of improving production and packaging efficiency, easy operation, and preventing brown sugar from sticking and clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

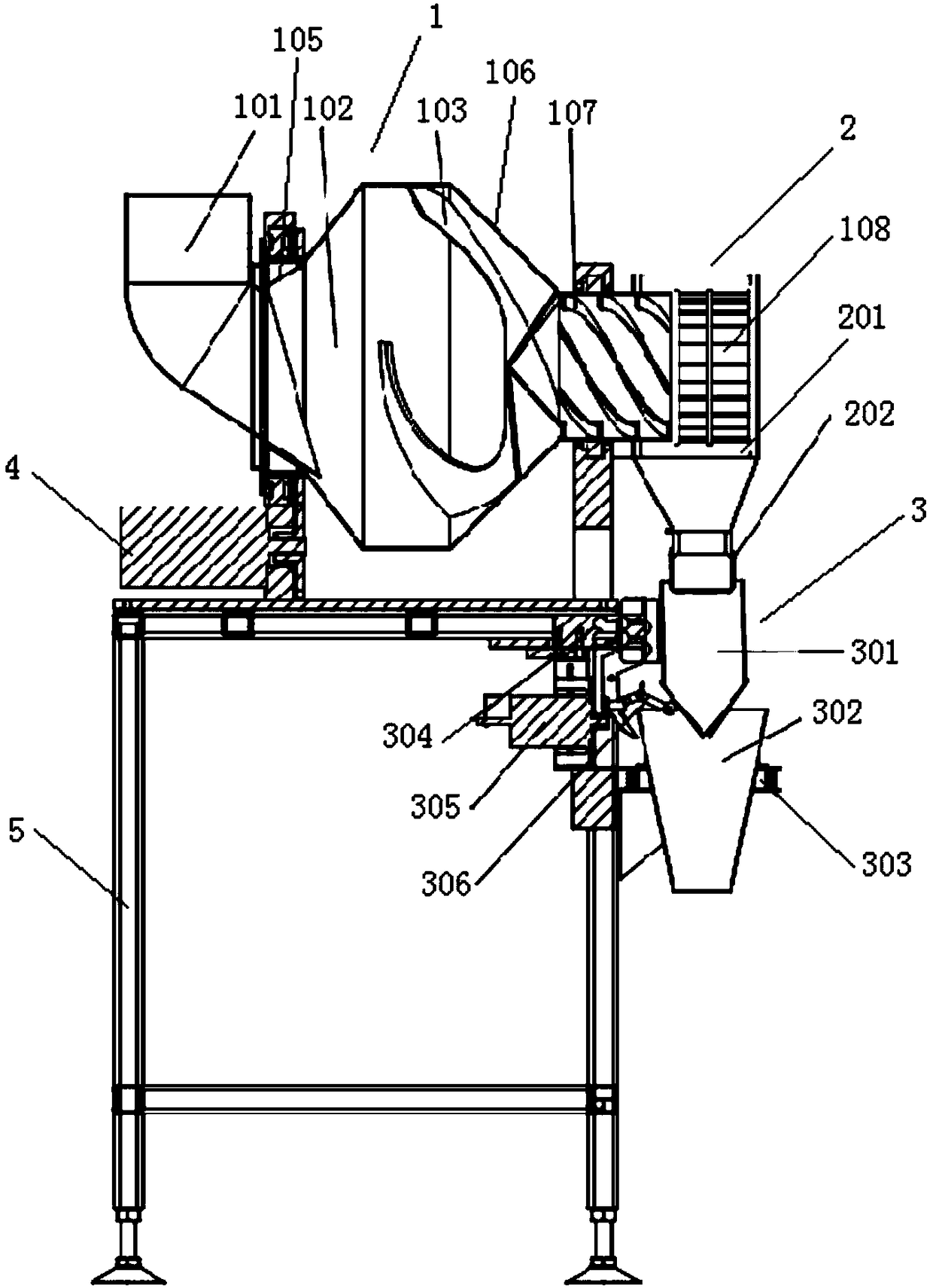

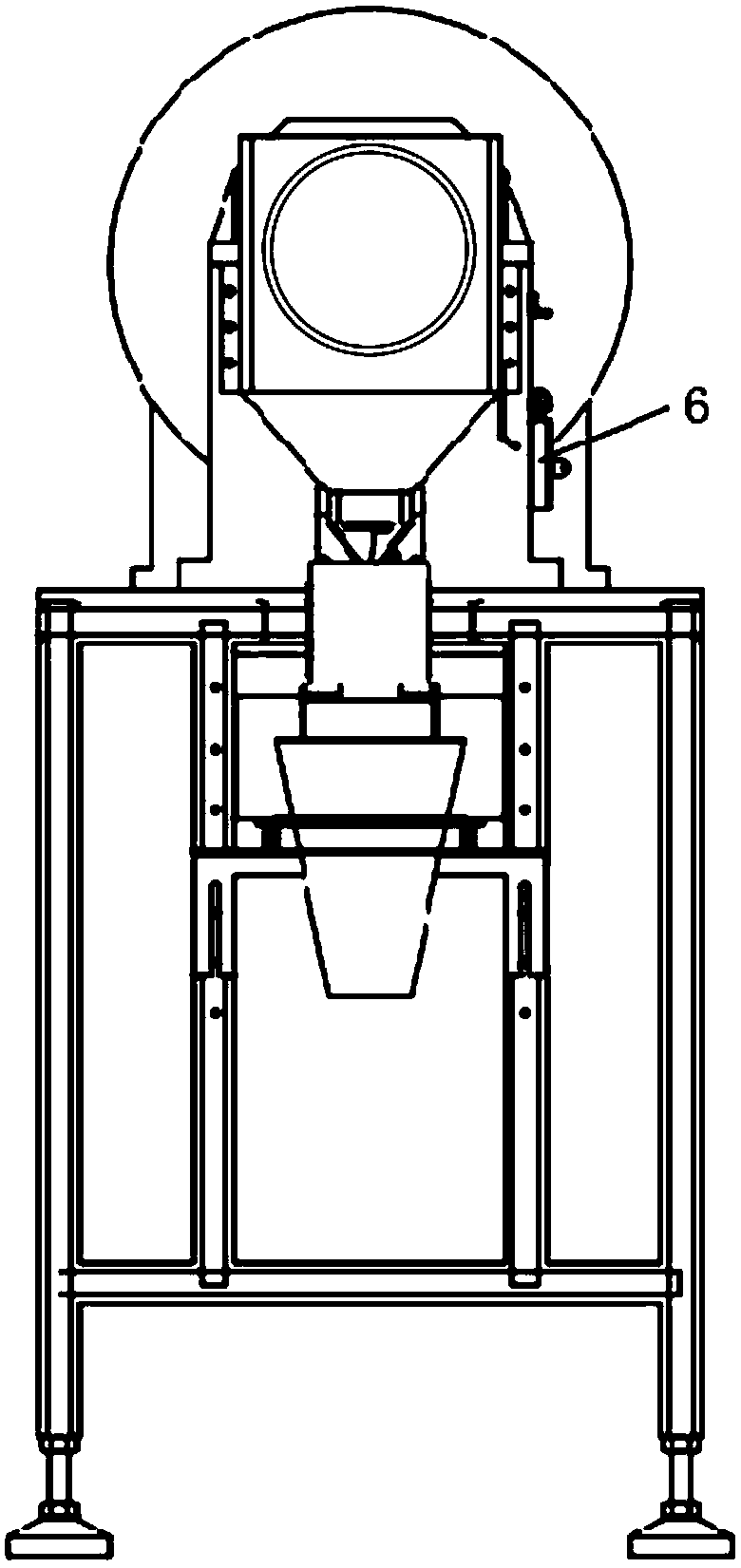

[0026] Anti-sticky non-extrusion brown sugar quantitative dispensing machine, such as figure 2 , image 3 As shown, it includes a frame 5, a feeding device 1, a quantitative switch valve 2, a quantitative metering device 3 and a transmission device. Both the feeding end and the discharging end of the conveying device 1 are installed on the frame 5 through the raceway, the feeding end of the conveying device 1 is connected with the motor 4 through the transmission device, and the discharging end of the conveying device 1 is connected with the quantitative switch The material storage cavity 201 of the valve 2 is butted. Quantitative on-off valve 2 and quantitative metering device 3 are installed on the same side of frame 5 , quantitative on-off valve 2 is installed directly above quantitative metering device 3 , and quantitative on-off valve 2 communicates with quantitative metering device 3 through first valve 202 .

[0027] Such as Figure 4 As shown, the conveying device ...

Embodiment 2

[0030] The working process of the anti-sticking and non-extruding brown sugar quantitative dispensing machine is as follows:

[0031] 1. Pour the brown sugar from the feeding bin 101, the brown sugar enters the mixing bin 102 through the feeding slideway, and the motor 4 drives the transmission device to drive the stirring bin 102 to rotate, so that the brown sugar can be repeatedly lifted in the mixing bin 102 ;

[0032] 2. When the brown sugar is lifted and falls, the guide plate 103 will send a certain amount of brown sugar into the spiral distribution mechanism 104, and the spiral distribution mechanism 104 will rotate with the mixing bin 102, and the brown sugar will flow evenly through the spiral blade 1042. In the storage chamber 201 of the quantitative switching valve 2, the brown sugar flows into the quantitative metering device 3 after passing through the first valve 202;

[0033] 3. When the amount of brown sugar flowing out reaches the required weight, the load cell...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap