Rapid blind plate switching device

A fast-switching, blind-plate technology, applied to valve devices, valve operation/release devices, sliding valves, etc., can solve the problems of reduced production time, worker poisoning risks, and impact on efficiency, so as to reduce leakage and meet safety and The needs of the process, the effect of protecting the safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

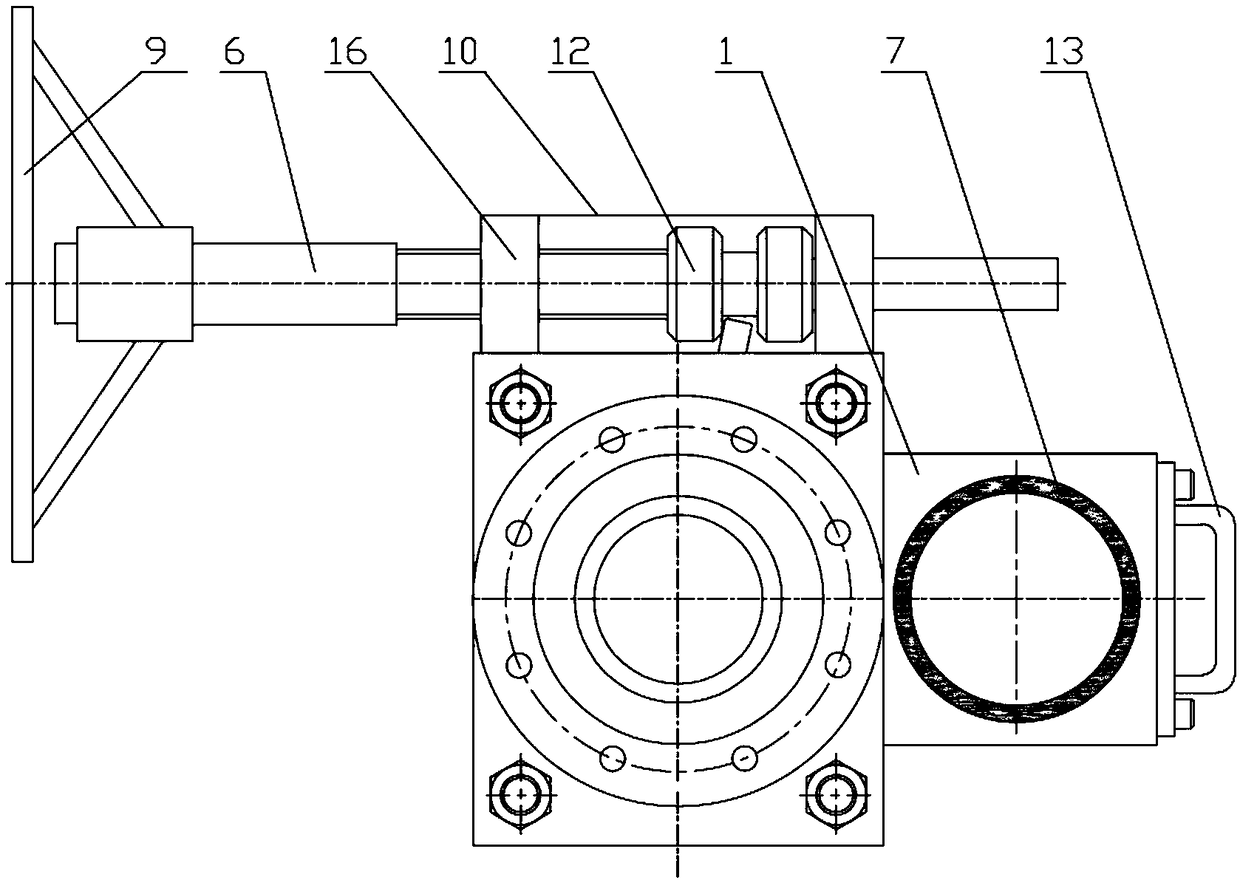

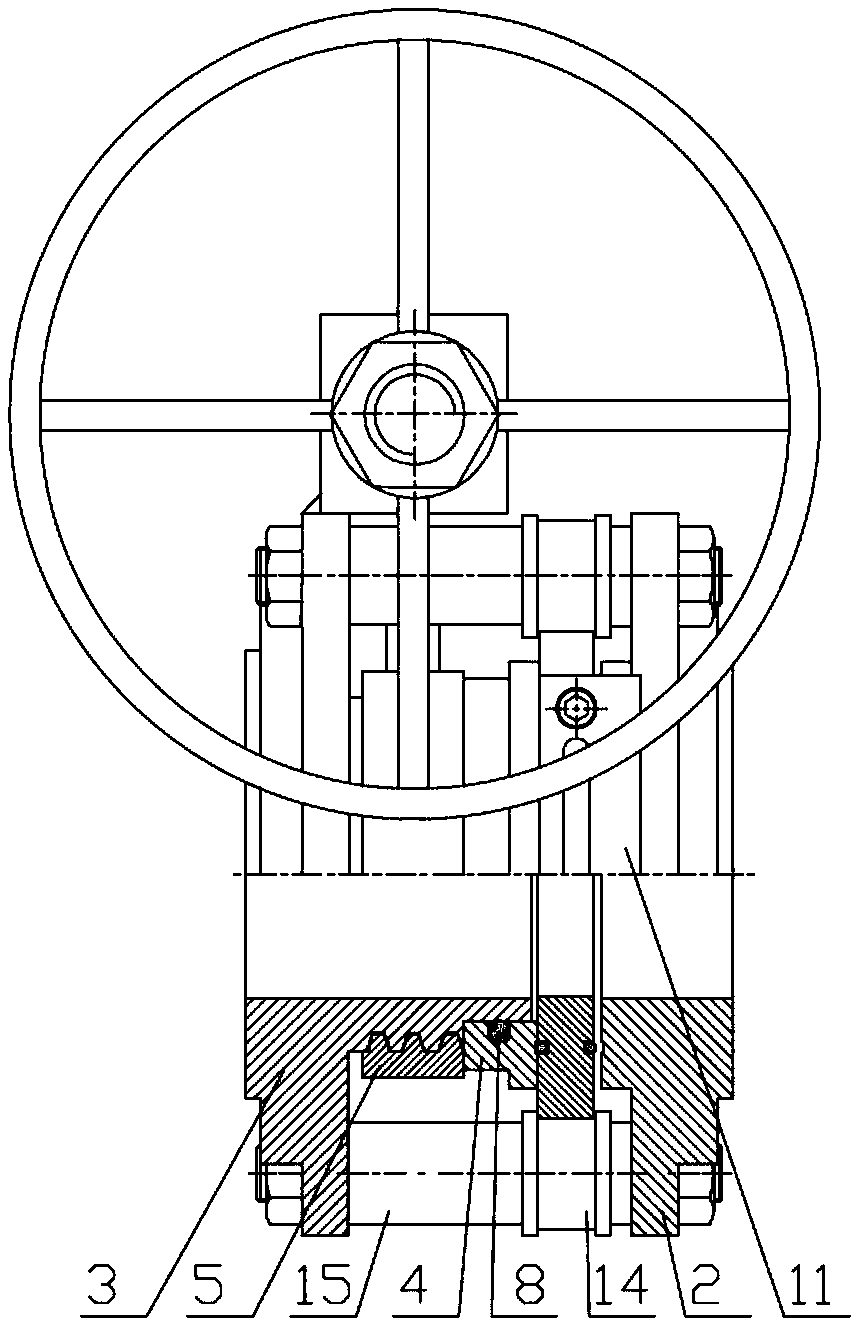

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] like figure 1 and figure 2 As shown, the present invention is a fast switching device for a blind plate, which includes a blind plate 1, a connecting support frame I2, a connecting support frame II3, a sealing seat 4, a transmission nut 5, a transmission rod 6, a seal I7, a seal II8, Hand wheel 9, indicating plate 10, baffle plate 11, baffle ring 12, handle 13, rolling ring 14, support ring 15, transmission support platform 16;

[0038] The support ring 15 is arranged between the connection support frame I2 and the connection support frame II3, and a stud is set in the support ring 15;

[0039] The connection support frame I2, the connection support frame II3 and the support ring 15 are fastened together by stud nuts to form the overall structure of the support device;

[0040] The sealing seat 4 is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com