Valve with anti-freezing function

A valve and function technology, applied in the field of valves with antifreeze function, can solve the problems of low practicability, user inconvenience, and the valve cannot be used normally, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

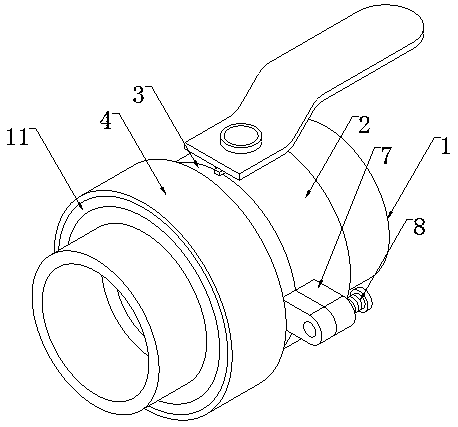

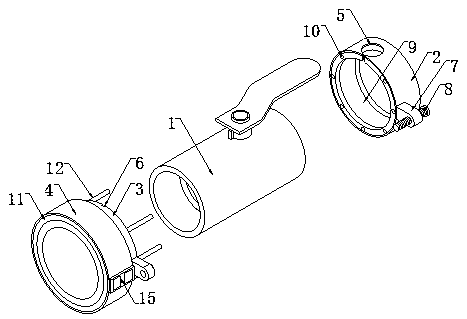

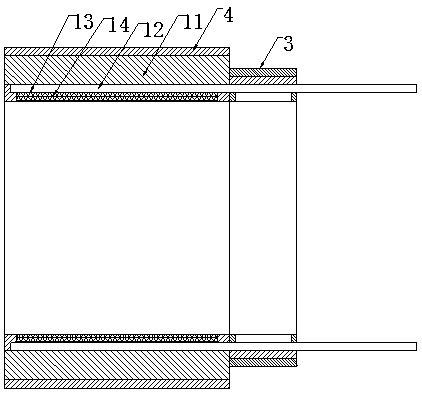

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a valve with antifreeze function of the present invention includes a valve body 1 and a first cylinder 2, and the valve body 1 is preferably FW-1001 type, and the first cylinder 2 is interspersed with one side of the valve body 1. One side of the top end of the first cylinder 2 is provided with a first slot 5, one side of the first cylinder 2 is provided with a connecting cylinder 3, and the inner side of the first cylinder 2 and the connecting cylinder 3 is embedded with an annular heat conducting block 9, And the annular heat conduction block 9 is made of copper metal, the side of the top of the connecting cylinder 3 is provided with a second slot 6, and the second slot 6 and the first slot 5 are matched with the top of the valve body 1, and the valve The other side of the main body 1 is inserted with a second cylindrical body 4, and one side of the second cylindrical body 4 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com