Electrode type hot water boiler module

A technology for hot water boilers and electrode boilers, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex control, inapplicability to small and medium-sized heat users, and heavy installation and commissioning workload to achieve safety high performance, maintain high efficiency operation, simplify the control mode and the effect of installation and commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

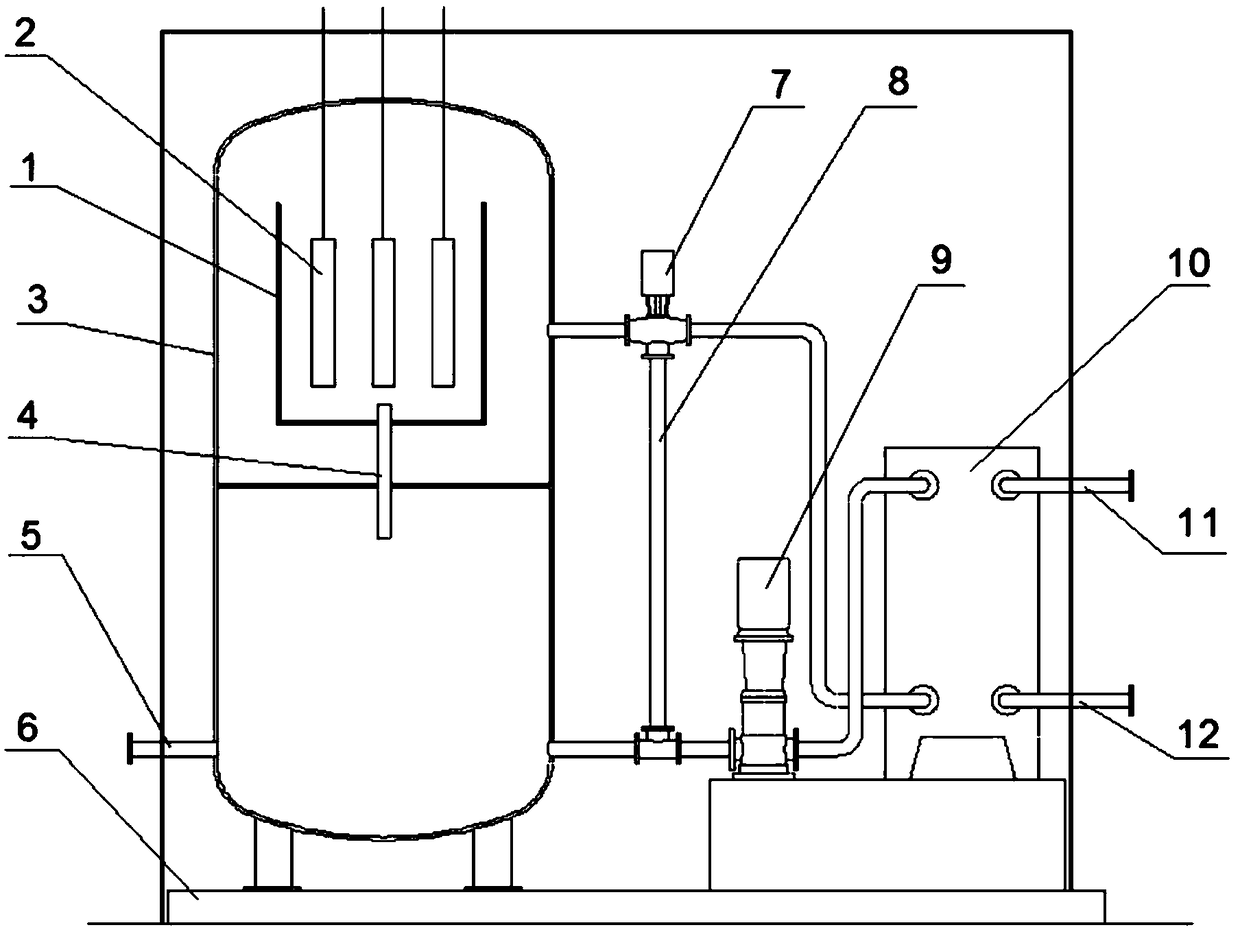

[0014] In the electrode type hot water boiler, when the voltage between the electrodes (phase electrode and zero electrode) is constant and the electrolyte concentration is constant, the number of ions in the unit volume remains unchanged. At this time, the contact area between the electrode and the electrolyte solution determines the heating power. size. The immersion depth of the electrode is changed by adjusting the height of the electrolyte liquid level, thereby changing the contact area between the electrode and the electrolyte solution, and the purpose of regulating the heating power can be achieved.

[0015] The present invention will be further elaborated below by specific embodiment:

[0016] Such as figure 1 As shown, the electrode type hot water boiler module includes an electrode boiler body, a circulating water pump 9, a heat exchanger 10, and an electric three-way valve 9. The lower part of the electrode boiler body is connected to the suction port of the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com