A wing installation and fixing mechanism

A fixed mechanism and wing technology, which is applied to self-propelled bombs, offensive equipment, projectiles, etc., can solve the problems of the thickness of the mounting seat, differences, and difficulty in ensuring assembly consistency, and achieves easy and quick disassembly and assembly, and aerodynamic performance. The effect of reducing and lowering the requirements for fit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

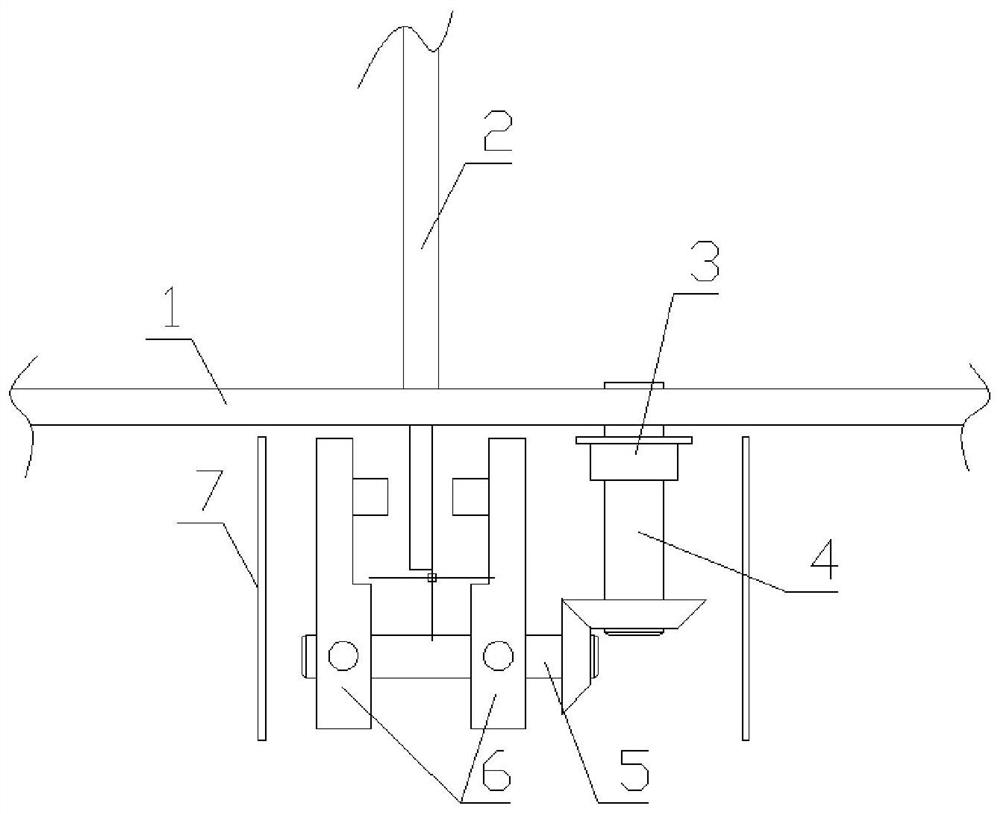

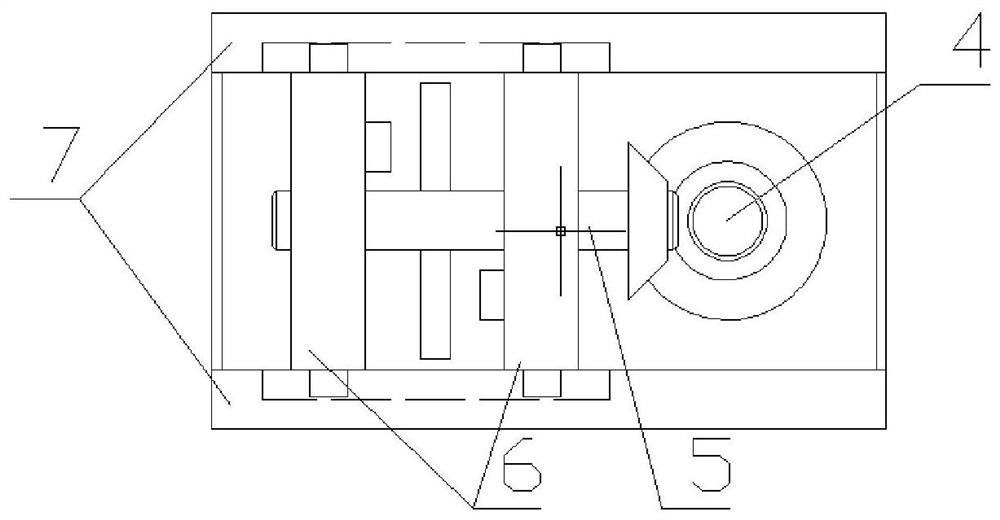

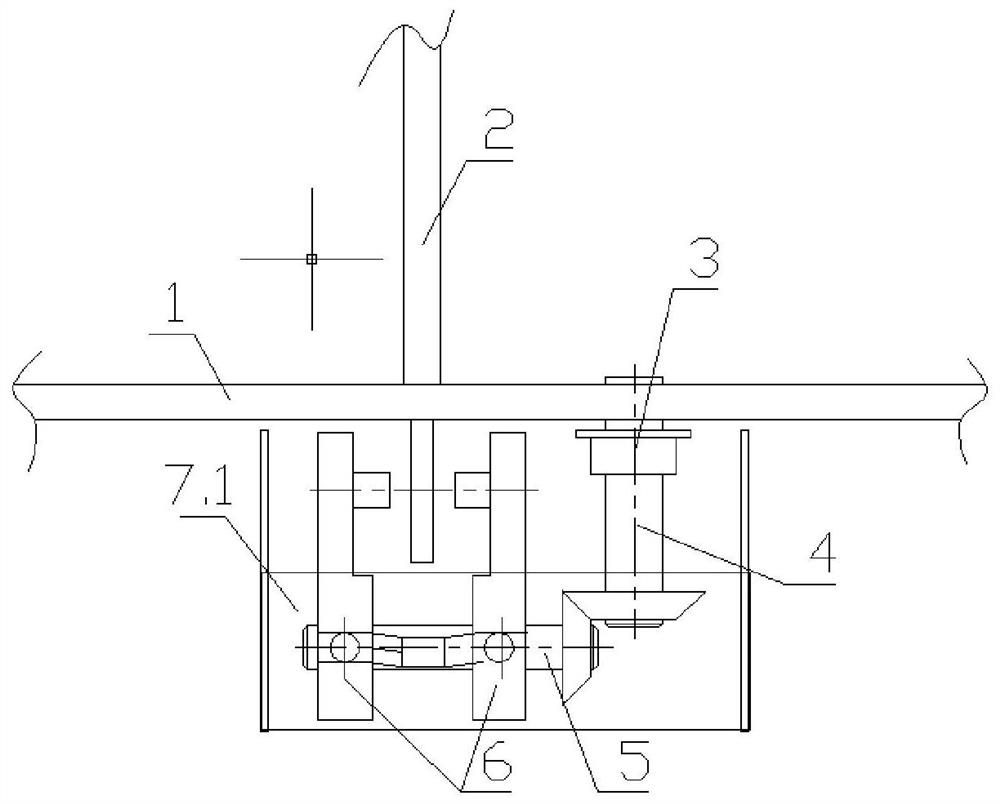

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] The invention mainly consists of two sets of helical gear transmission rods, a symmetrical clamping plate and a housing. One set of helical transmission rods passes through the skin and connects with the self-locking nut with self-locking function placed in the housing under the skin. Only the screw head with a "cross" groove is exposed outside the skin for operation. The symmetrical clamping plate is installed on the two sides of the shell through two hanging shafts. There are threaded holes with different rotation directions in the middle of the symmetrical clamping plate, which are connected with another set of helical gear transmission rods. The pinion gears are meshed, and the two transmission rods are in the form of a right angle. The casing connects each mechanism as a whole, and is fixed in the shell itself. There are grooves with guiding groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com