A lead connecting device for electric power field wiring

A wire connection, on-site technology, applied in the direction of connection/disconnection, connection, and contact assembly/disassembly, etc., can solve problems such as affecting the wire connection effect, large gap between bending coils, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

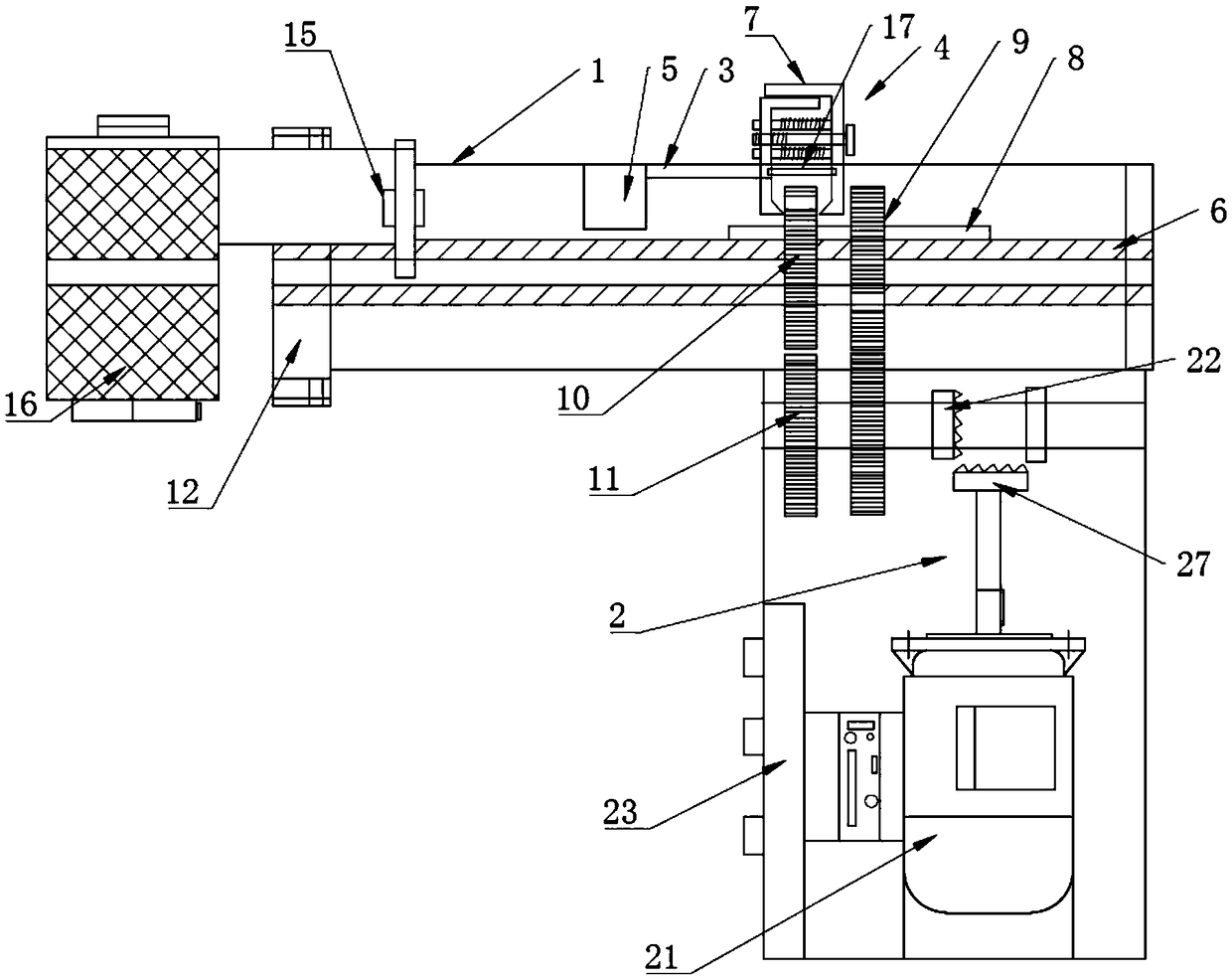

[0044] Such as Figure 1-Figure 7 As shown, a wire connection device for field wiring of electric power includes a bushing 1 and a power part 2, a sliding groove 3 is opened on the upper part of the bushing 1, and a clamping part 4 is slidably installed in the sliding groove 3, and the clamping part 4 The lower part is fitted with a sliding gear 10, and the end of the sliding groove 3 is provided with a ring groove 5 arranged around the center of the casing 1. The inside of the casing 1 is fitted with a rotating shaft 6, and the outside of the casing 1 is provided with a mounting hole. A thread clamping part is installed in the hole, and the thread clamping part is installed coincident with the center of the rotating shaft 6; a central hole is opened at the center of the rotating shaft 6, and a sliding key 8 is installed on the rotating shaft 6, and a fixed gear 9 is installed on the sliding key 8 With the sliding gear 10, the lower part of the sleeve with the feather key 8 is...

Embodiment 2

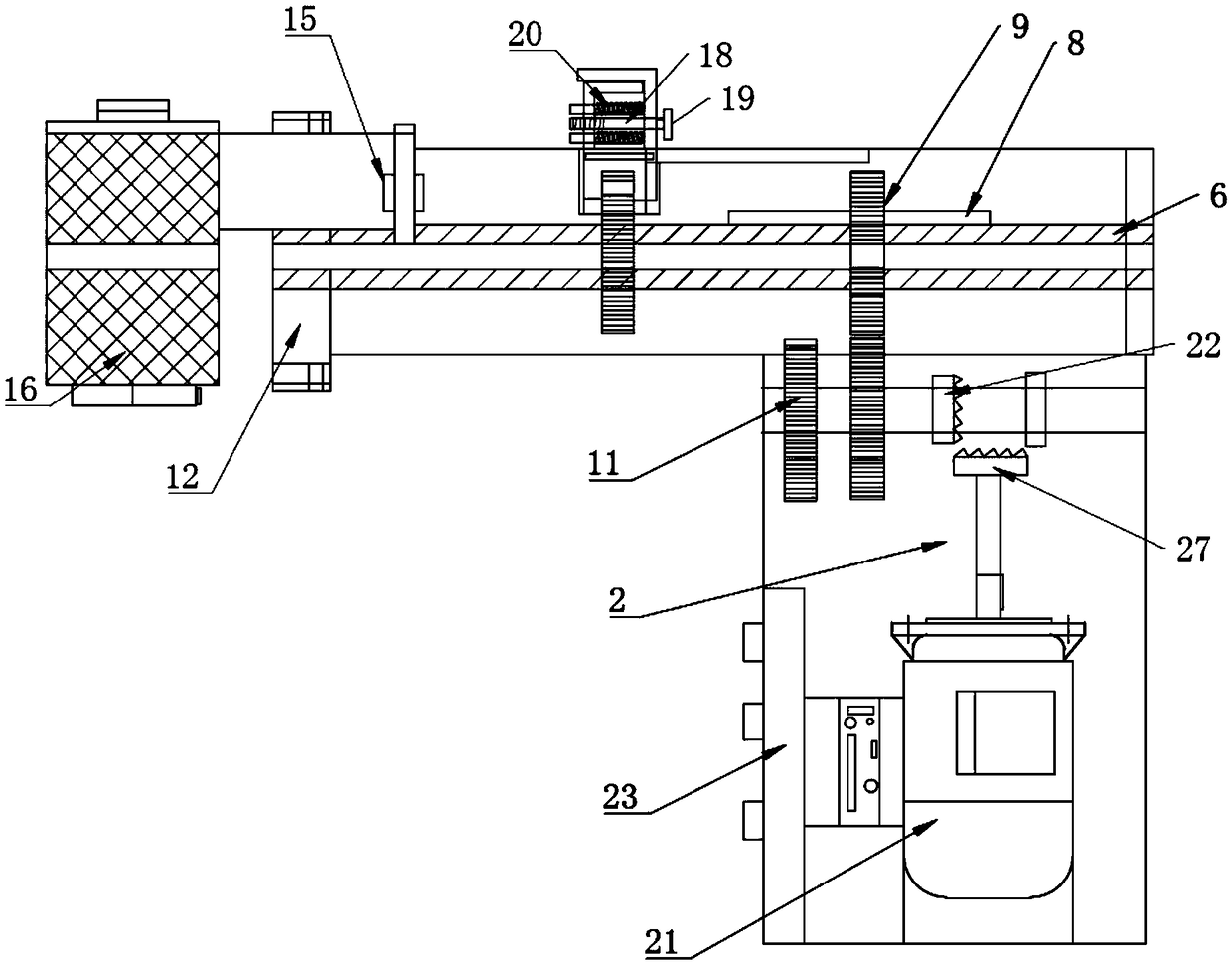

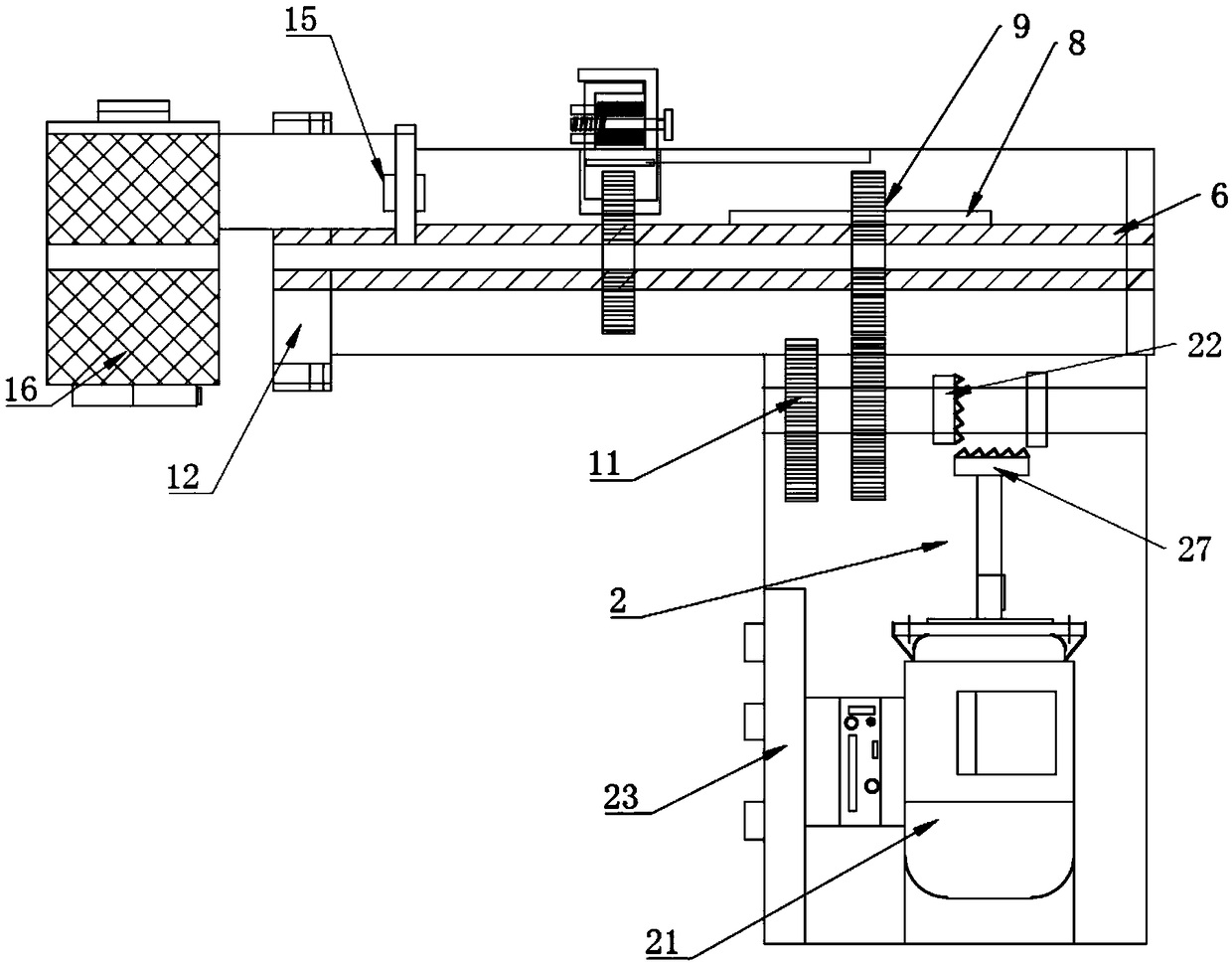

[0059] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 lies in the following two aspects:

[0060] The clamping frames 7 are hinged, and the part of the adjusting column 18 set between the clamping frames 7 is set with a return spring; the clamping frame 7 has a simple structure and is easy to operate;

[0061] The power part 22 comprises a first sprocket 24 and a rotating handle 26, the sprocket is installed on the power shaft, the rotating handle 26 is equipped with a second sprocket 25 connected with the sprocket by a chain, and the outer diameter of the second sprocket 25 is larger than The outer diameter of the first sprocket 24; the first sprocket 24 and the second sprocket 25 are connected by a chain, and the large outer diameter of the second sprocket 25 can drive the power gear 11 to rotate more quickly, save energy, and can achieve connection role.

[0062] Using the above-mentioned technical scheme, the following are two actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com