Formaldehyde adsorption machine

A formaldehyde adsorption and adsorption net technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of firm looseness, adsorption of large particles of dust and inconvenient cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

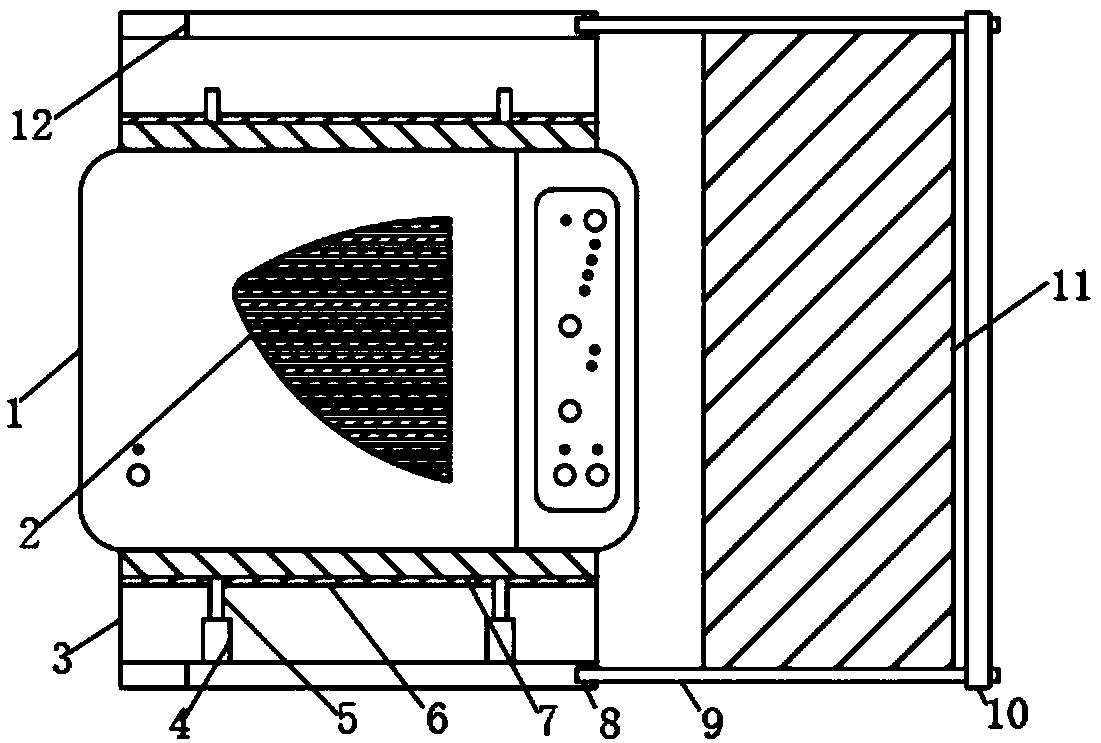

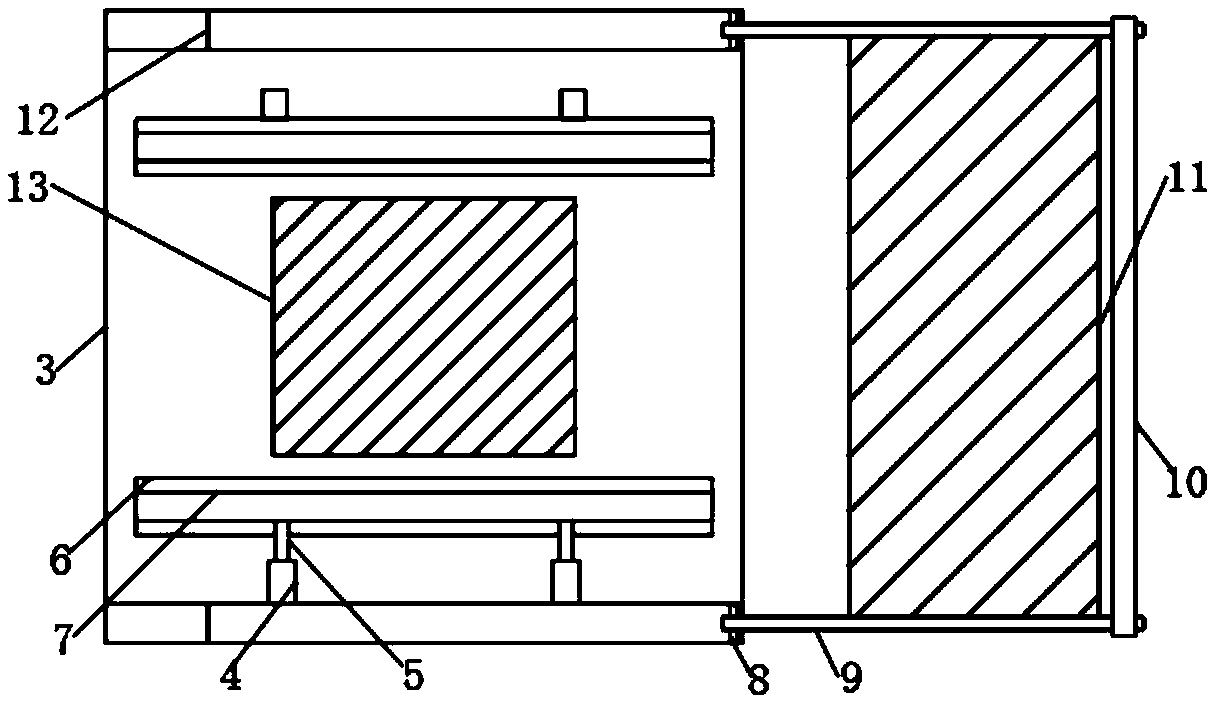

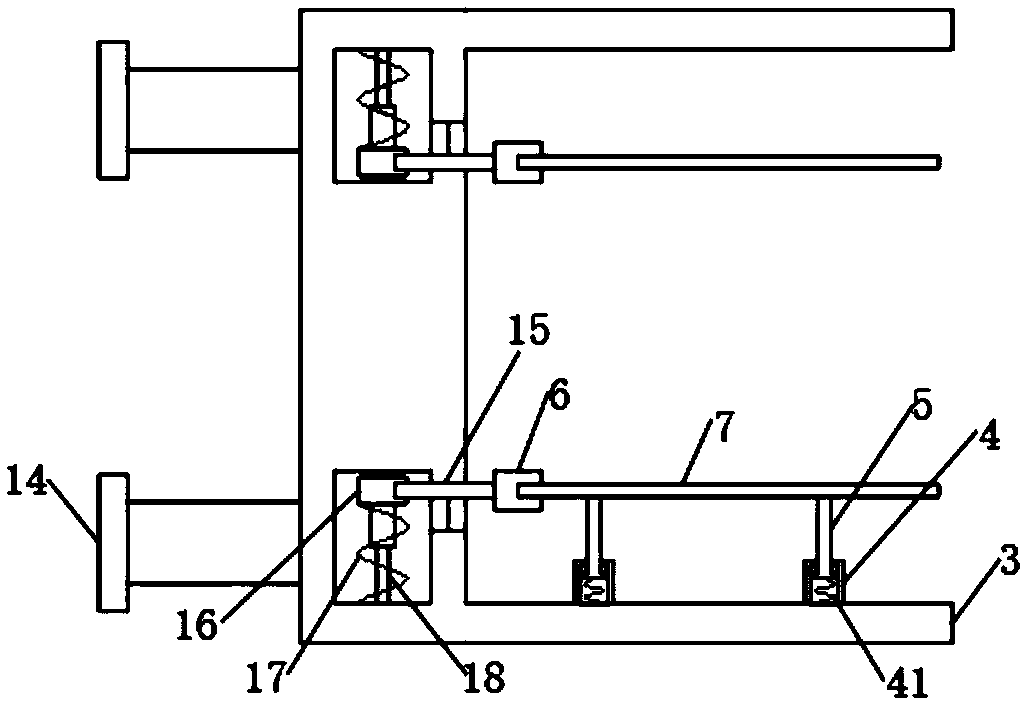

[0021] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a formaldehyde adsorption machine, including a formaldehyde adsorption body 1, an adsorption net 2 and a fixed box 3, the adsorption net 2 is located in the middle of the surface of the formaldehyde adsorption body 1, and the formaldehyde adsorption body 1 is located in the middle of the fixed box 3, fixed The bottom surface of the box 3 is screwed and connected with four fixed columns 4, the top and bottom surfaces of the formaldehyde adsorption body 1 are respectively screwed and connected with the limiting plate 7, and the top of the fixed column 4 is provided with a movable column 5, And the top of moving column 5 is connected on the bottom surface of limit plate 7, and the surface of fixed box 3 top and bottom is symmetrically provided with moving bar 15, and one end of moving bar 15 is connected with moving plate 6 by screwing, and the fixed box 3 The four corners of the...

Embodiment 2

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a formaldehyde adsorption machine, including a formaldehyde adsorption body 1, an adsorption net 2 and a fixed box 3, the adsorption net 2 is located in the middle of the surface of the formaldehyde adsorption body 1, and the formaldehyde adsorption body 1 is located in the middle of the fixed box 3, fixed The bottom surface of the box 3 is screwed with four fixed columns 4, and the interior of the fixed columns 4 is provided with a second spring 41, and the top and bottom surfaces of the formaldehyde adsorption body 1 are connected with the limiting plate 7 by screws. , the top of the fixed column 4 is provided with a moving column 5, and the top of the moving column 5 is connected to the bottom surface of the limit plate 7, the surface of the fixed box 3 top and the bottom are symmetrically provided with a moving bar 15, and one end of the moving bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com