Corn processing integrated machine having breaking and separating function and using method of maize processing integrated machine

A technology of corn processing and integrated machine, which is applied in the direction of grain processing, etc. It can solve the problems of poor crushing effect, inability to separate impurities and corn cobs, and achieve good crushing effect and avoid falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

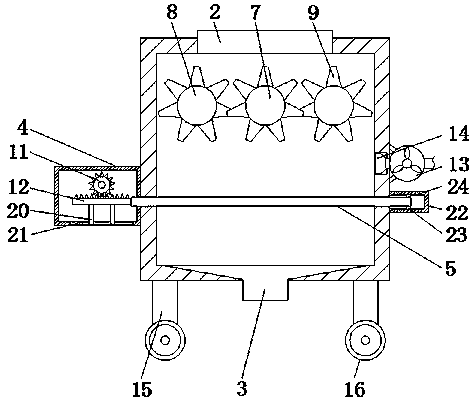

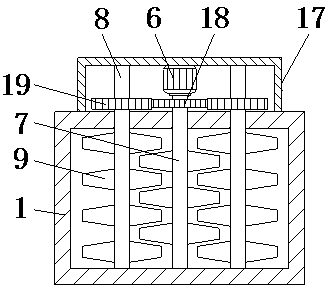

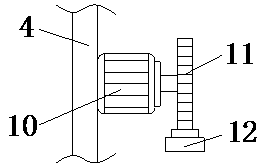

[0035] First, the threshed corn cobs are added into the box body 1 through the filling pipe 2, and then the first motor 6 drives the first smashing rod 7 to rotate, and the first smashing rod 7 also drives the second gear 18 to rotate, and the second gear 18 drives the third gear 19 to rotate through the meshing of the teeth, and the third gear 19 also drives the second smashing lever 8 to rotate simultaneously, and the first smashing lever 7 and the second smashing lever 8 drive the smashing block 9 to rotate, which can The corn cob is smashed, and then the second motor 10 drives the first gear 11 to rotate, and the first gear 11 drives the tooth plate 12 to shake back and forth in the first placement box 4 through the meshing of the teeth, and the tooth plate 12 also drives the filter screen 5 in the Shaking in the box body 1 can separate the crushed corncobs and impurities. At the same time, the fan 13 is running, and the dust and impurities generated in the box body 1 can b...

Embodiment 2

[0037] In embodiment one, add following operation:

[0038] Step (1) It is necessary to select the corn before filling, and select the moldy corn cobs and impurities.

[0039] First, the threshed corn cobs are put into the box 1 through the filling pipe 2, and the moldy corn cobs and impurities are selected, and then the first motor 6 drives the first crushing rod 7 to rotate, and the first crushing rod 7 also drives the The second gear 18 rotates, the second gear 18 drives the third gear 19 to rotate through the engagement of the teeth, and the third gear 19 also drives the second smashing lever 8 to rotate, the first smashing lever 7 and the second smashing lever 8 Drive the broken block 9 to rotate, corn cobs can be broken, and then the second motor 10 drives the first gear 11 to rotate, and the first gear 11 drives the tooth plate 12 to rock back and forth in the first placement box 4 through the meshing of the teeth. The toothed plate 12 also drives the filter screen 5 t...

Embodiment 3

[0041] In embodiment two, add following operation:

[0042] Step (4) After the discharge, the corn cobs can be stored in ammoniated cement cellar or earth cellar.

[0043] First, the threshed corn cobs are put into the box 1 through the filling pipe 2, and the moldy corn cobs and impurities are selected, and then the first motor 6 drives the first crushing rod 7 to rotate, and the first crushing rod 7 also drives the The second gear 18 rotates, the second gear 18 drives the third gear 19 to rotate through the engagement of the teeth, and the third gear 19 also drives the second smashing lever 8 to rotate, the first smashing lever 7 and the second smashing lever 8 Drive the broken block 9 to rotate, corn cobs can be broken, and then the second motor 10 drives the first gear 11 to rotate, and the first gear 11 drives the tooth plate 12 to rock back and forth in the first placement box 4 through the meshing of the teeth. The toothed plate 12 also drives the filter screen 5 to sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com