Air blowing system with rotary air pipe

A technology of rotating air and air ducts, which is applied in the field of air blowing systems, can solve problems such as time-consuming and laborious, fixed blowing nozzles, and low operating efficiency, and achieve high efficiency and high quality of completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

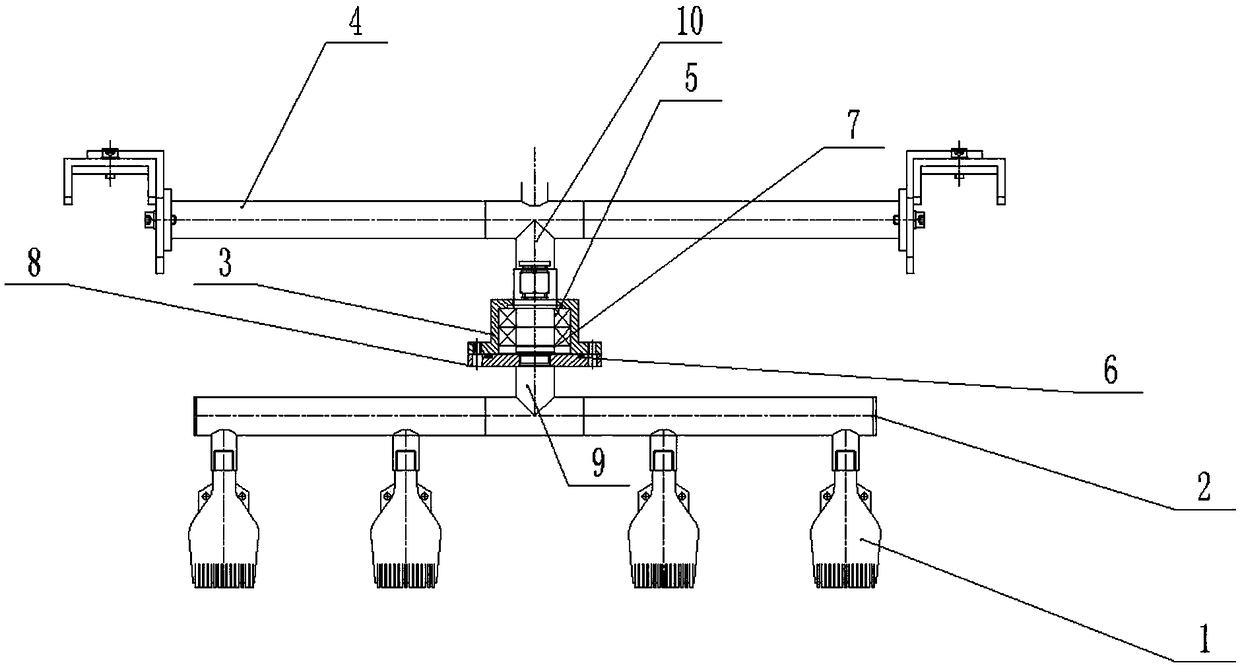

[0016] Please refer to the figure, in the embodiment of the present invention, a blowing system with a rotating air duct includes a blowing nozzle 1, an air duct 2 and a fixed air duct 4; a plurality of blowing nozzles 1 are fixed on the air duct 2, and Evenly distributed on the air pipe 2, the rotating main pipe 9 is connected to the midpoint of the air pipe 2 through a tee, and the branch pipe 10 is connected to the fixed air pipe 4, and the branch pipe 10 is connected to the rotating body 3 through the rotating body. On the main pipe 9, and the rotating body 3 communicates with the rotating main pipe 9 and the branch pipe 10, so that the wind in the fixed air pipe 4 enters the rotating body 3 through the branch pipe 10, and then enters the rotating main pipe 9 from the rotating body 3 And enter in the air pipe 2, blow out by the mouthpiece 1 on it.

[0017] The rotating body 3 is fixedly connected to the connecting flange 8 welded to the end of the rotating main pipe 9 by b...

Embodiment 2

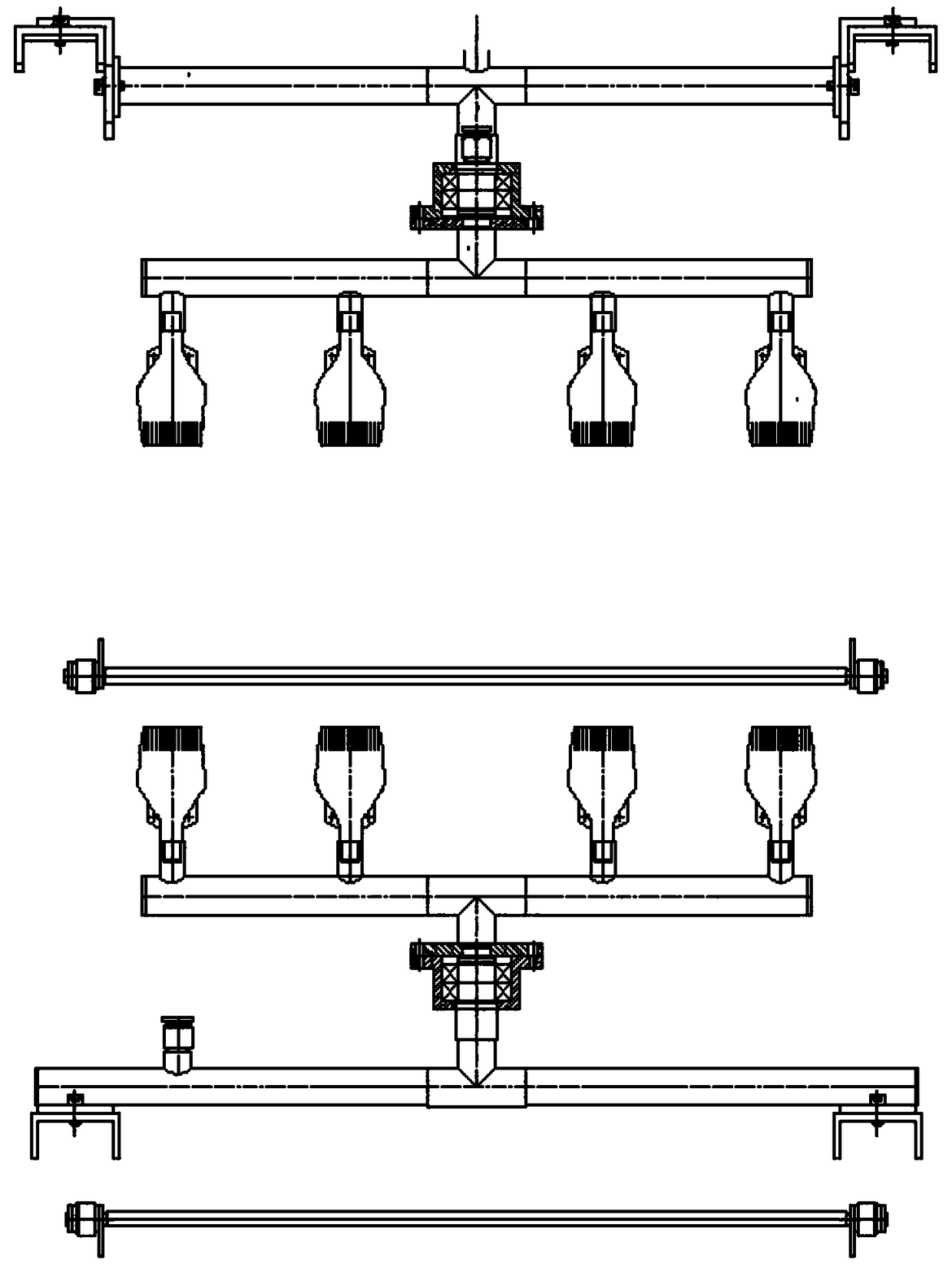

[0020] The fixed air duct 4 is connected with a plurality of branch pipes 10, and the branch pipes 10 are all connected with the same structure as the branch pipes 10 in Embodiment 1, so that multiple groups of air blowing systems can operate simultaneously.

Embodiment 3

[0022] The system can be arranged opposite to each other so that the blowing nozzles 1 on both sides are relatively blown, and air can be blown from both sides correspondingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com