Liquid crystal display cleaning device

A technology for cleaning devices and liquid crystal screens, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., capable of solving problems such as increasing the complexity of cleaning and mixing cleaning liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

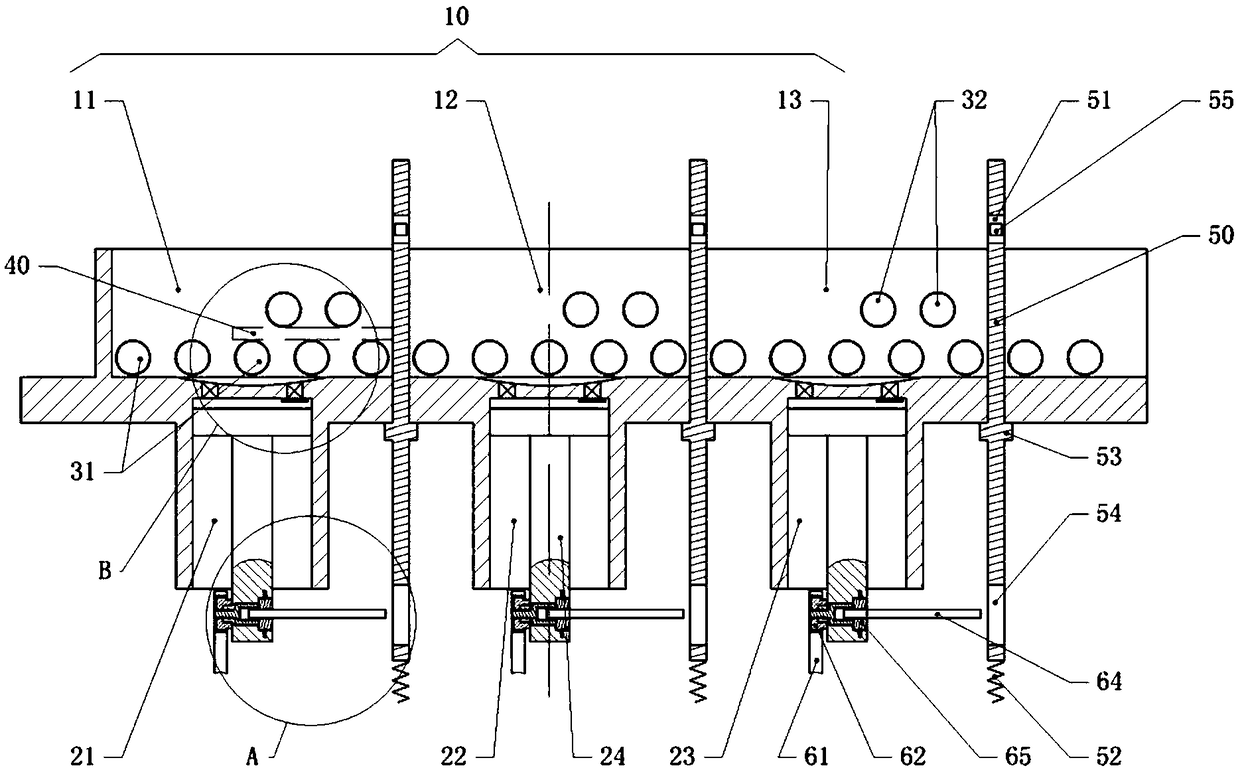

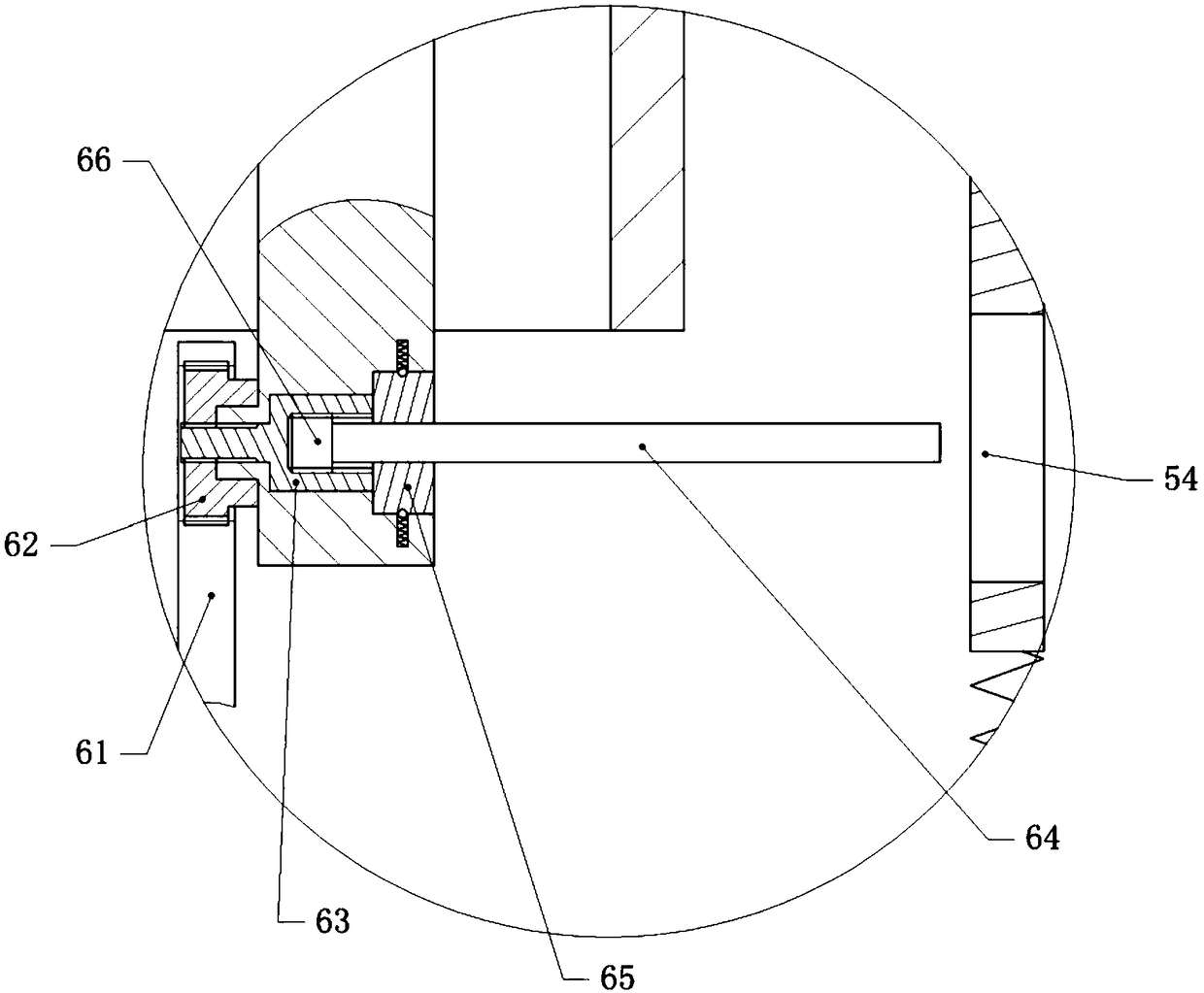

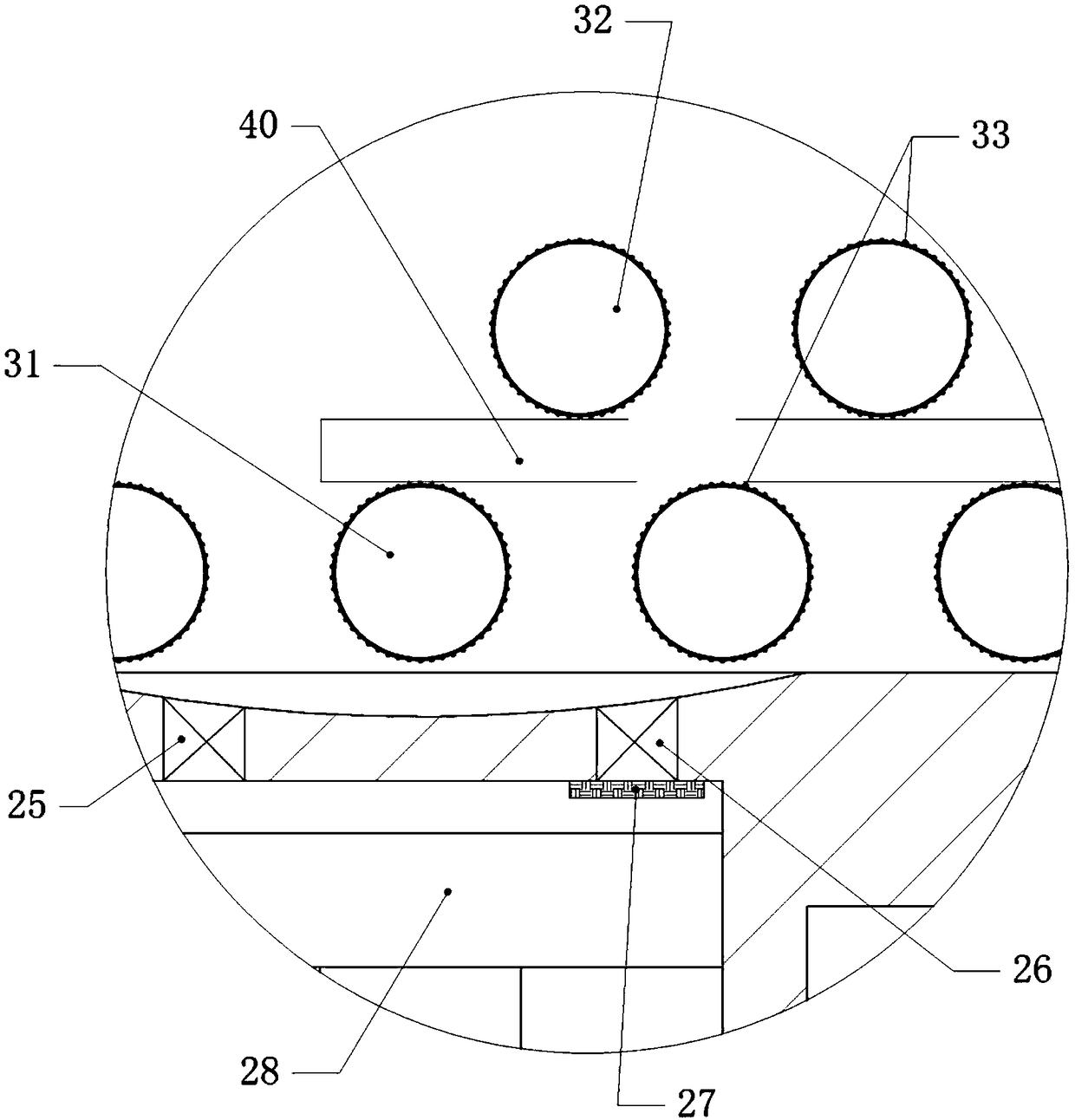

[0021] The reference signs in the drawings of the description include: cleaning tank 10, first cleaning chamber 11, second cleaning chamber 12, third cleaning chamber 13, first cleaning liquid storage chamber 21, second cleaning liquid storage chamber 22, third cleaning liquid storage chamber Cleaning liquid storage chamber 23, push rod 24, liquid inlet one-way valve 25, liquid outlet one-way valve 26, filter screen 27, piston 28, transmission roller 31, pressure roller 32, rubber sleeve 33, LCD screen 40, partition 50. Passing hole 51, return spring 52, limit edge 53, linkage groove 54, push switch 55, rack 61, gear 62, threaded sleeve rod 63, square shaft 64, torque controller 65, threaded section 66.

[0022] as attached figure 1 As shown, the liquid crystal screen 40 cleaning device includes a cleaning tank 10 and a driving mechanism. The bottom of the cleaning tank 10 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com